Static Gets Worse at Higher Line Speeds: Keys Toward Maintaining Good Static Control

- Published: May 13, 2024

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Static charges on webs can cause discharges that can ignite fires, shock operators and damage digital control systems. The static charges can also cause cut sheets to stick and edge trim to jam. The static control system limits the charge levels to avoid these problems.

Think about one of your most productive lines. Profits would be even better if we could just increase the line speed by 20 percent. What do we need to do to make this happen?

One of the many things to think about is static control. Why do static levels increase with line speed? What can we do about it? Static levels increase with line speed for two reasons: Air entrainment and charge motion. First, let's look at air entrainment.

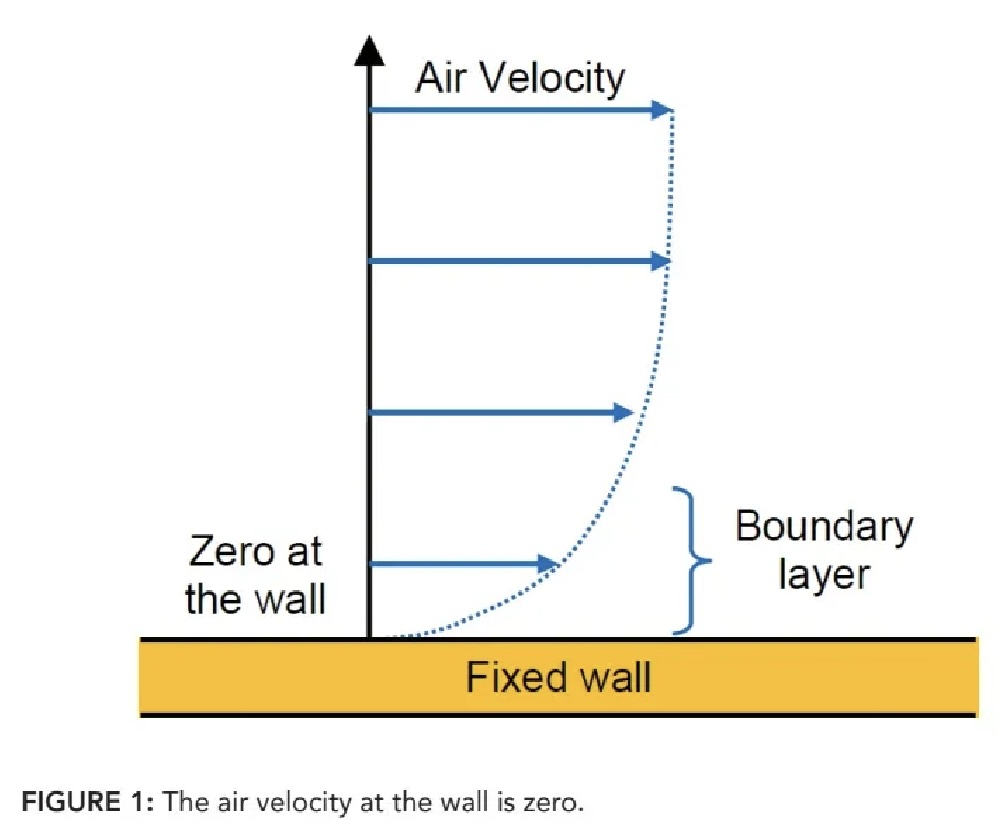

Air Entrainment — A moving web pumps air caused by the air boundary layer. The air in Figure 1 moves at a constant velocity far from the wall. However, the air velocity at the wall surface is zero, which is the "zero slip condition." The boundary layer is the transition from "zero slip" at the wall surface to constant velocity far from the wall.

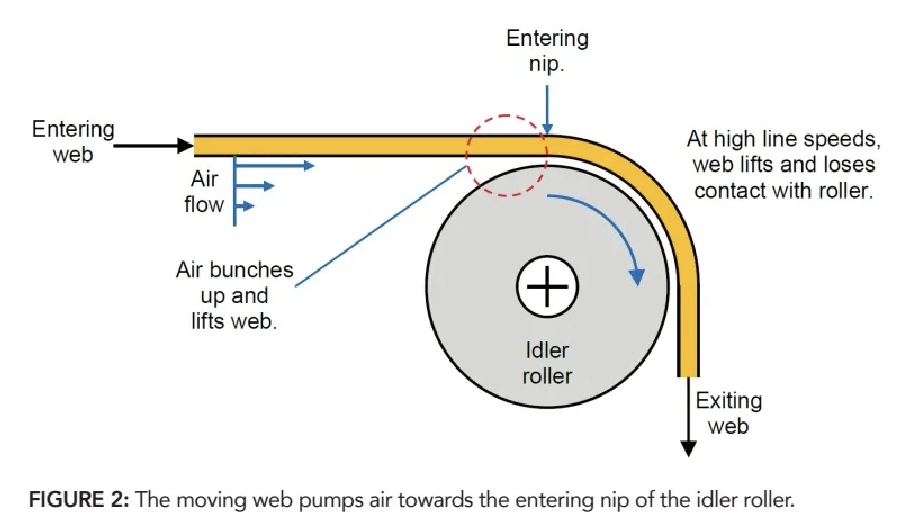

A boundary layer also forms at the surface of the moving web in Figure 2. In this case, the air far away from the web is still (zero velocity) and the "zero slip condition" means that the air at the web surface moves with the web. As the air approaches the entering nip where the web first touches the idler roller, the air must escape out at the edges of the web and the air pressure increases. This happens at each roller the web touches.

As the line speed increases, the air pressure increases enough to lift the web so that it loses contact with the roller. The line speed where this happens depends on the web tension and the venting pattern on the roller surface.

As the web begins to lift and lose contact with the roller, two things happen that increase static charging:

- Bearing drag slows the roller so that it does not turn at line speed. Static charging increases because the web has intermittent sliding contact with the slowly turning roller.

- With low traction, the web is not constrained and begins to weave. Static charging increases caused by the more aggressive motion by web guider rollers.

Web planarity is very important. If the web is baggy in the center, then air entrainment will easily lift the center of the web causing bands of static charges along the edges where the web remains in contact with the roller.

Spreader rollers help prevent wrinkles by stretching to make the web wider. These rollers are designed to have sliding contact that also charges the web. More aggressive spreading means higher web charging.

To maintain good static control at higher speeds, five keys are:

- Increase web tension to maintain good traction with idler rollers.

- Use more open roller venting patterns to maintain good traction.

- Use more planar webs to minimize charging from spreader rollers.

- Install static dissipaters exiting web guiders if needed.

- Install static dissipaters exiting spreader rollers if needed.

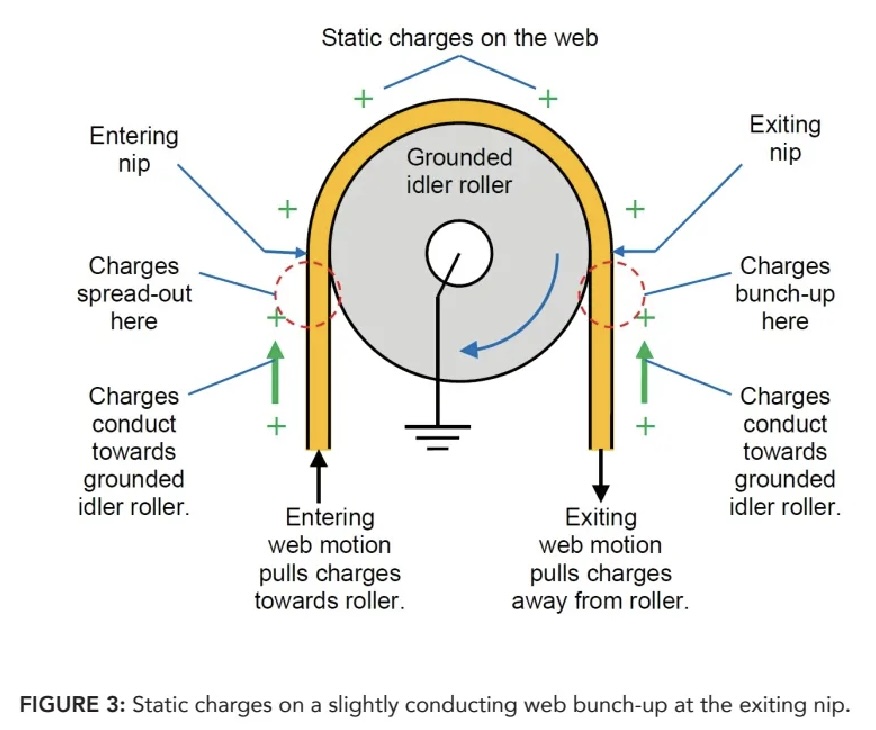

Charge Motion - For a web that has some conductivity (e.g., coated with a water-based coating that retains some water), Ken Clum, my former colleague at the Eastman Kodak Company, found that line speed and the static charge distribution interact as illustrated in Figure 3 (see: K. Clum, "Equilibrium Distribution of Charge on a Moving Conducting Film Web," IEEE Transactions on Industry Applications, Vol. 25, No. 1 Jan/Feb 1989, pg. 36-40).

The web in Figure 3 has a little bit of conductivity (surface resistivity < 10+11 Ohm/sq.) meaning that charges on the web can move at speeds comparable to the line speed. For a web that does not move, charges move by conduction towards the grounded roller indicated by the green arrows.

When the web moves, charges are carried along by the web. Charges move by both conduction and convection (web motion). For the entering web, both conduction and the web motion move charges towards the idler and the charges spread out a little bit near the entering nip where the web first touches the roller.

On the exiting web, conduction pushes the charges towards the idler roller and the web motion pulls the charges away from the roller. The result is that charges bunch up near the exiting nip where the web loses contact with the roller.

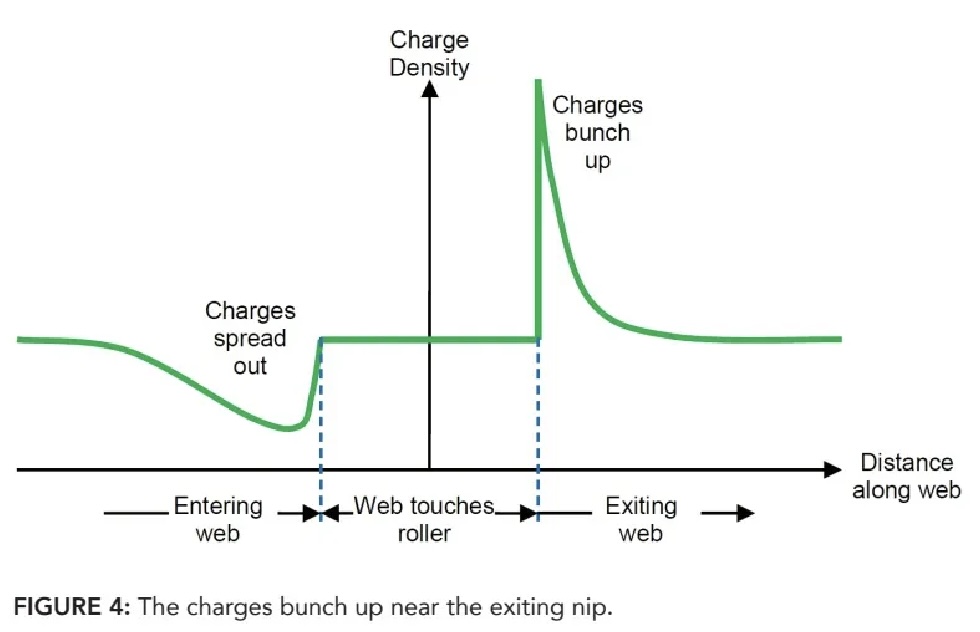

Clum's calculations illustrated in Figure 4 were confirmed with clever experiments with Bob Pazda, another of my former colleagues at the Eastman Kodak Company using a segmented roller (see: K. Clum, and R. Pazda, "Segmented roller: A device for measuring charge density on a moving conducting web," Journal of Electrostatics, Volume 24, Issue 1, 1989, Pages 21-32, ISSN 0304-3886, https://doi.org/10.1016/0304-

3886(89)90005-3).

Bunching up of charges is proportional to (line-speed) * (resistivity). So, if the line speed increases by 20 percent, the web resistivity must decrease by 20 percent to have the same charge densities.

To maintain good static control at higher line speeds, a sixth key is:

- For webs with little bit of conductivity (web resistivity < 10-11 Ohm/sq.), increasing the line speed means that we need to decrease the web resistivity.

In summary, static levels increase when a line runs faster for two reasons: Air entrainment and charge motion. Lack of web planarity worsens charging caused by air entrainment. These six keys can assist in maintaining good static control for higher line speeds.

About the Author

Dr. Kelly Robinson writes on static issues occurring in converting processes. Robinson founded Electrostatic Answers, has 40-plus years experience in industrial problem solving and was named Top Manufacturing Consulting Services Provider 2023 by Managing MFG. He can be reached at Kelly.Robin-son@ElectrostaticAnswers.com.