Passive, Active and Intelligent IQ Electrostatic Eliminators

- Published: August 21, 2023

By Manuel C. Blanco, Senior Electrical Design Engineer, Simco-ION, an ITW Company

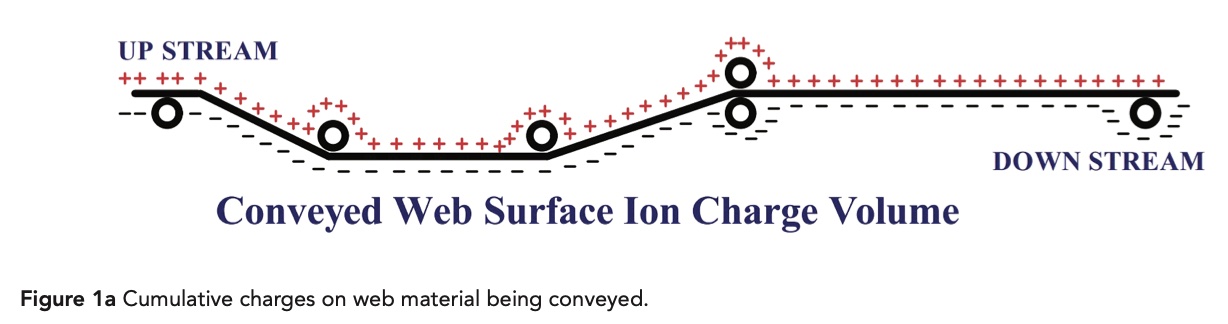

Across a wide array of industries, static electricity is the principle obstacle to achieving higher processing speeds and the main cause of quality problems. Significant surface charge levels build up as a by-product of the material being conveyed, Figure 1a. Fundamentally, charges exist as two polarities (+) Positive and (-) Negative ions. The attraction and repulsion force between the two charges is defined by Coulomb’s Law, which states opposite charges will attract and similar charges will repel each other.

The processed conveyed material is in motion, and typically stretched/put under surface tension as it wraps along several types of circular rollers made up of chemically dissimilar, insulative or conductive materials than that being processed. Insulators have their electrons strongly bounded to each atom, prohibiting the movement of charge freely so charge concentrations can be localized and have a natural tendency to spread to the surface because of repulsive forces. Conductors have their electrons loosely bound to each atom so they can move about allowing conductive charge flow within the conductor.

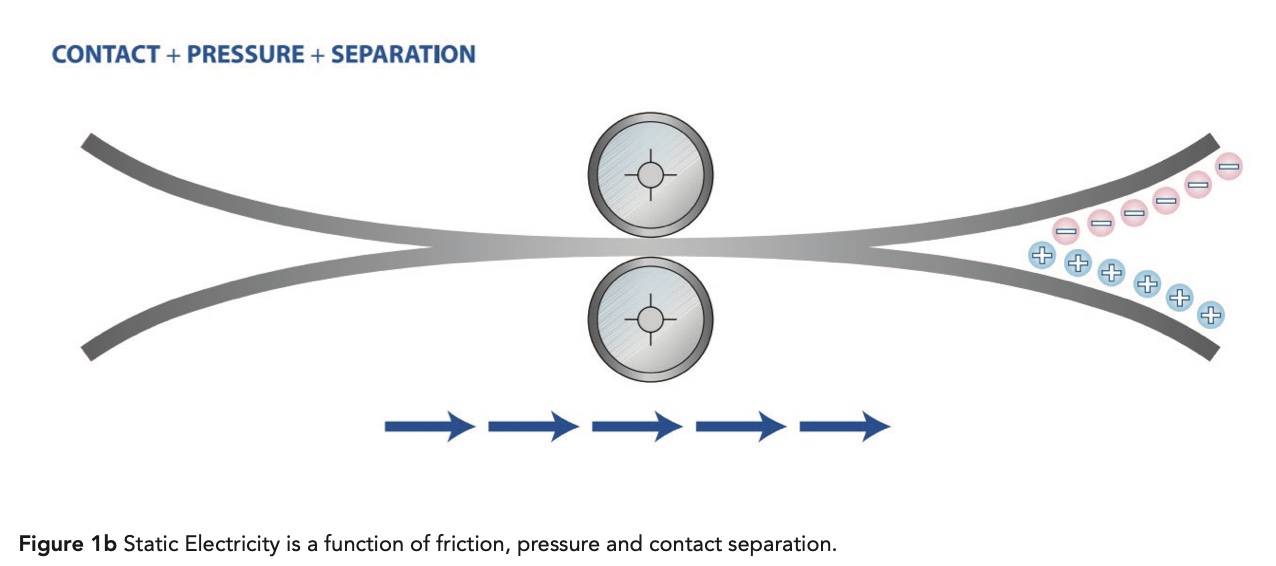

These dissimilar insulative or conductive surfaces meet, come in contact with each other, and separate along the circular, curved, tangential contour of the roller, Figure 1b. This results in triboelectric charge distribution governed by Gauss’s Law which relates the distribution of electric field and electric flux across an enclosed surface as a function of the electric charge, surface area and the normal angle that forms between the electric field lines and the web surface.

At the contact interface of both surfaces, insulative and conductive, an electron migration exchange takes place such that when the dissimilar surfaces separate the surface material which has given up electrons becomes (+) Positively charged and the surface that has gained electrons becomes (-) Negatively charged. The charge polarity of each surface is governed by the triboelectric series, which is an organized enumerated list of insulative and conductive materials that can acquire a Positive, Neutral or Negative charge based on charge strength.

These electrostatic charges now in motion accumulate to high levels, leading to the formation of elevated voltages and currents spread along the conveyed web materials surface and are related to the moving web parameters involved: Web Width [cm], Web Speed [FPM], Material Surface Charge Density [nC/cm2], and roller Velocity [cm/s]. Other charge level dependencies include ambient temperature [°C] and air humidity[g*m3].

Process conveyed web materials have been well known to accumulate high charge concentration levels ranging from 1KV to 100KV. At these charged levels, ambient dust and fiber particulates cause contamination, manufacturing non-uniformities, material damage, spontaneous arc flash discharge, damage to sensitive programmable logic controllers (PLC) electronics and become a shock hazard to operators putting their safety and those around them at risk.

As a result of these operational consequences the selection of electrostatic eliminator technology — Passive or Active: AC, Pulsed DC or Intelligent Systems — needs to be understood and correctly implemented in the manufacturing process to reduce charge levels to a manageable degree where material damage is reduced, quality yield is improved and operator safety is paramount, with minimal operational down time for maintenance.

Passive, Active and Intelligent Eliminators

Modern manufacturing demands requiring faster web speeds, increased productivity volumes and through put have led to elevated charged levels and production bottlenecks requiring the need for more optimized electrostatic control with intelligence. To overcome these process obstacles, several evolutionary technologies in electrostatic eliminators are available to the customer based on their process requirement needs. An understanding of static eliminator technology is essential for implementing and solving electrostatic problems.

Electrostatic Eliminator Technology

Passive Jurassic Methods, such as Tinsel, use fine copper filaments arranged to concentrate charge conduction via direct grounding to the machine frame. Tinsel filaments are directly coupled to the web at very close proximity, but do not make physical contact, and can flake off over time contaminating the conveyed material.

These exposed copper filaments are usually less than one inch away from the web, causing the exposed strands to break into corona utilizing the energy charge flow of the moving conveyed web material producing a single polarity. Over time these copper filament strings will attract contaminants and get dirty causing the corona onset voltage to in- crease resulting in large volumes of charged material passing through untreated, un-neutralized and stripping the web.

Tinsel has no current limiting capability, since it is not resistively coupled, so if charge levels aggressively build up you can arc and punch through the material or at worst cause an incendiary event and expose operators to safety hazards. There is no intelligence with passive ionization — it has no way to homogenize the ion current across the web and cannot provide web charge condition or operational information to establish performance metrics.

Mechanical mounting is a challenge since traditionally it is draped across the surface area of the conveyed material, without making contact. Other slightly improved but fair mounting methods involve magnets for affixing and suspending in air or tinsel

can be purchased in the form of a rod for rigidity, and for obtaining some web distance space regularity. However, extreme caution must be exercised when reorienting a passive ionizer during operation since the device can be drawn into a pinch point causing additional safety concerns. Tinsel and other passive equivalents are not recommended due to various inconsistencies, impracticalities, shortcomings and extremely low efficiencies.

AC Systems: In AC ionization we have a single power supply that produces alternating high voltage sine waves of both polarities to an array of single point emitter pins on a bus. Each independent emitter pin is current-limited and resistively coupled to the web resulting in homogenous generation of both (+) Positive and (-) Negative ions throughout the surface of the conveyed material from a single pin.

Since AC ionization uses a single point emitter to produce opposite polarity ions, some ion production is lost due to recombination effects. Also, ion production does not occur immediately since the voltage at the emitter points must be greater than 3KV to break the pin into corona. As a result of the wave shape, only about 40 percent of the sine wave peaks produce ionization, rather than the entire cycle.

These AC systems are also shockless to the operator posing no safety hazards and can be securely mounted on a machine frame or gantry arm suspended over the web without making contact. Despite the minor ion loss, higher neutralization efficiencies can be obtained because separate ion voltage levels are produced. Also, by implementing analog feedback techniques to isolate the ion production at each half cycle, an indication of bar and web performance can be obtained for maintenance and cleaning of the electrostatic eliminator.

Pulsed DC Systems utilize two individual power supplies for generating separate (+) Positive and (-) Negative ions. Square pulses used by this technology allow near 100 percent ion production and more instantaneous power supply turn-on. Recombination effects are minimized by positioning and spacing of emitter pin pairs.

These systems can apply both polarities to a single emitter pin or to separate, closely spaced pair of emitters points each independently running on a separate voltage bus. These Pulsed DC systems are also shockless having each emitter pin resistively coupled and current limited, homogenizing its output across the bar and web.

Separate high-voltage generation for each polarity means we have flexibility for adjusting several tuned parameters such as voltage, current, power, phase, frequency and modulation with analog feedback to achieve ion balance and maintain neutralization at farther distances from the target web material. This added flexibility translates to stable mounting onto the machine frame or gantry arm at various distances facing the web, adding more focalized and adaptable electrostatic elimination solutions.

Intelligent Systems utilize the same method of ion production as Pulsed DC Systems with the addition of intelligent microprocessor-controlled math algorithms adaptively formulated for electrostatic solutions, e.g., closed loop feed-back, (CLFB). Individual switch-mode power supplies — utilizing high frequency switching magnetics enabling a multitude of switch-mode topologies — are used for the high-voltage generation of (+) Positive and (-) Negative ions. They can be miniaturized and embedded into the electrostatic eliminators based on the required output voltage, current and power levels implementing regulated ion production independent of charged web load demands.

This also permits the embedded power supplies to be driven off +24Vdc for ease of interfacing and installation to programmable logic controllers (PLCs), and can be powered with a DC wall adapter that utilizes power factor correction techniques to reduce electromagnetic interference noise and improve overall power system losses.

This intelligent technology facilitates the implementation of monitoring capabilities that capture real-time data of emitter pin and bar conditions as it interacts with the conveyed web material and can discern if any contamination, insulative or conductive, is affecting the bar efficiency by direct measurement of the ion currents generated and their charge interactions with the web.

The technology of electrostatic eliminators continues to evolve based on the developments of new materials and the manufacturing demands for faster processing speeds. Triboelectric charging of the conveyed web material continues to impede a multitude of manufacturing operations at these elevated speeds, but it does not have to be that way. Manufacturers have better active electrostatic neutralizer options available that can solve their static problems.

Advances in high frequency switched-mode power supply technology coupled with micro-controllers have led us to present-day state-of-the-art Intelligent Systems, that can implement closed-loop feedback, with Sensor technology for accurate measurement of field intensity at various locations of the charged web or target.

This intelligent Systems design approach allows for various configurations and facilitates the secure positioning of both electrostatic eliminators and sensors across the conveyed web for a complete picture of your electrostatic charge issues. In addition, PLC integration is possible with user-controlled alarms along with monitoring capabilities to give the manufacturing customers the flexibility for selective time interval data points and event logging for planned maintenance. This helps ensure improved process controls, reducing machine down time and increasing production volumes with minimum defects in a safe environment.

About the Author

At Simco-ION, an ITW company, Manuel C. Blanco develops new strategic product design initiatives and market design requests that directly impact the company’s portfolio in broad markets such as medical devices, food and beverage, automotive, flat panel displays, semiconductor devices, and material processing and conveyance. He is part of a team that has several patents in the areas of design, control and calibration methods of switch mode power supplies and high frequency magnetics, analog and digital circuit design as applied to the fields of electrohydrodynamic (EHD), and electrostatic neutralizing and charging systems.