Surface Tension and Wettability

- Published: May 02, 2024

Key Principles for Quality Production in Converting

By Melissa Lang, Vice President, Jemmco, LLC

Surface tension and wettability are essential principles for achieving quality production in converting processes. Whether involved in film extrusion, coating, laminating, printing or metallizing, converters must understand these factors to ensure the success of their final products.

Understanding Surface Tension and Wettability

Surface tension refers to the attractive force between molecules at the surface of a liquid, while surface energy is the term used when evaluating this force on a solid substrate. For simplicity, we’ll use “surface tension” for both liquids and solids in this article.

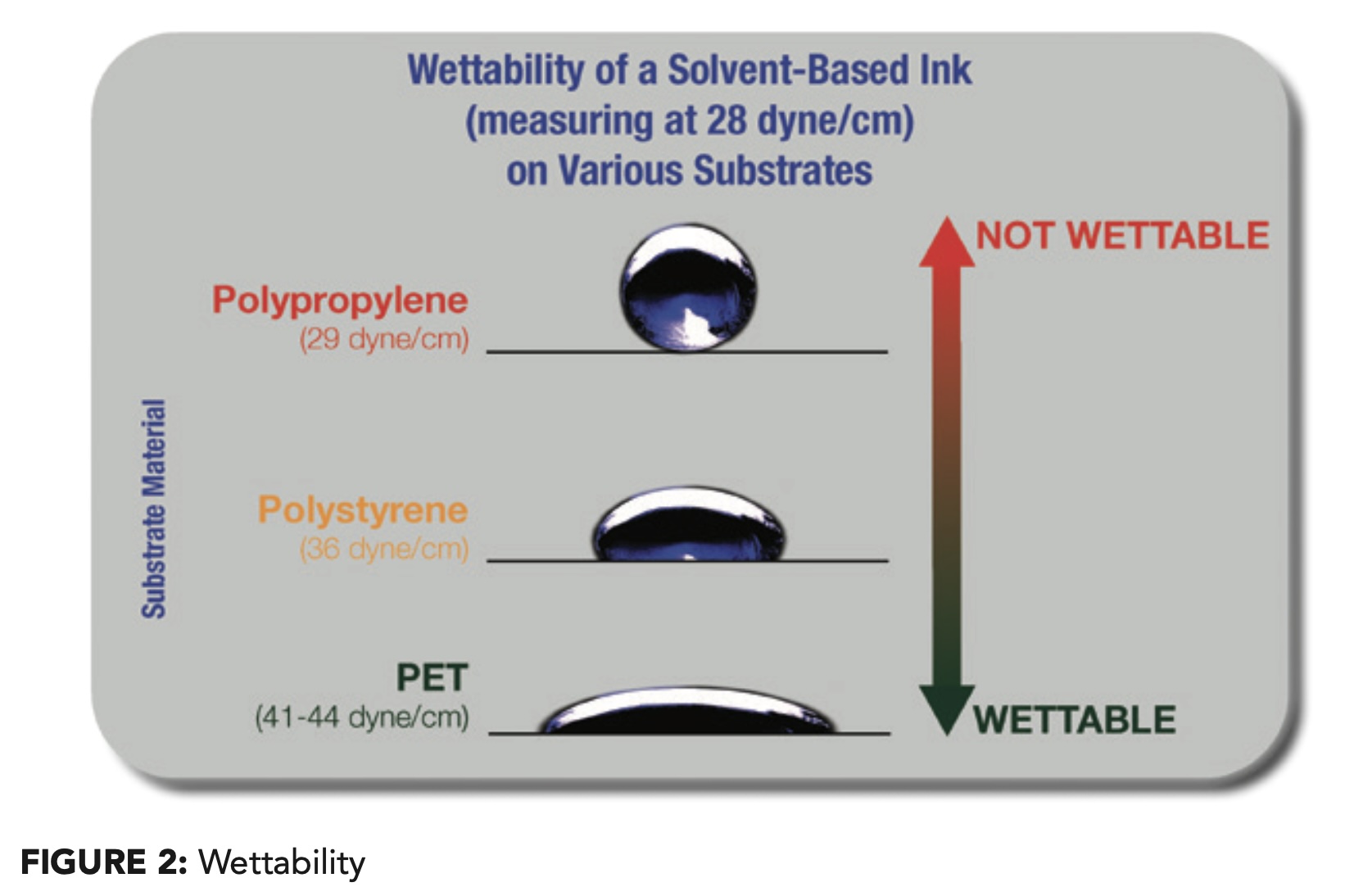

Surface tension plays a pivotal role in predicting how a liquid will spread when applied to a solid substrate — a characteristic known as wettability. A substrate with higher surface tension relative to a liquid will attract the liquid to its surface and spread it out easily (referred to as “wettable”). Conversely, a substrate with lower surface tension will cause the liquid to form into droplets (referred to as “non-wettable”).

The Importance of Surface Tension and Wettability

The basic principle of surface tension and wettability in converting is that for ink, adhesive or bonding agents to adhere successfully, the substrate’s surface tension must be higher than that of the liquid. If the substrate’s surface tension is lower, the liquid won’t spread properly, and adhesion will fail.

Fortunately, converters can use methods like corona treatment or flame treatment to increase the surface tension of substrates, or they can opt for pre-treated materials to improve adhesion.

Understanding materials and the fundamentals of surface tension and wettability is key.

Consider the following scenario: When a solvent-based ink with a surface tension level of 28 dyne/cm is applied to three commonly used substrates, it will exhibit distinct behaviors due to the varying surface tensions of the substrates (see Figure 2).

Whether utilizing untreated material, pre-treated material or conducting in-house corona treatment, surface tension testing serves as a simple yet effective means to prevent costly issues such as poor adhesion, excessive waste, ink rub-off and coating defects stemming from inadequate wettability.

Measuring Surface Tension

The industry-standard method for measuring surface tension involves using wetting tension fluid, also known as dyne test solution. This fluid contains varying concentrations of formamide and 2-Ethoxyethanol (cellosolve), as specified by ASTM-D2578, yielding surface tension levels ranging from 30 to 56 dynes/cm. Additionally, solutions ranging from 57-70 are available from select manufacturers, formulated through different concentrations of distilled water and formamide; these formulations are not yet incorporated into the ASTM-D2578 specification.

Various application methods for wetting tension fluid exist, which can be broken down into two main categories: Dyne solutions and dyne pens. Below is an overview of these application methods. Ultimately, selecting the best method will depend on your specific needs, application and production environment.

Key Considerations for Utilizing Dyne Test Products

While there are various dyne test application methods, each follow the basic principles for interpreting results outlined in the ASTM-D2578 specification, as summarized below.

- Using the lowest dyne solution level, lightly spread the dyne liquid over an area of approximately 1 in 2 of the test-substrate.

- Note the time it takes for the liquid to break up into droplets (reading should be made in the center of the liquid swipe). If the line holds for:

- MORE THAN 2 seconds: The substrate’s surface tension is greater than the dyne level of the tested solution. Retest using the next higher dyne level solution, incrementally, until you find the solution that holds for exactly 2 seconds.

- LESS THAN 2 seconds: The substrate’s surface tension is less than the dyne level of the tested solution. Retest using the next lower dyne level solution, incrementally, until you find the solution that holds for exactly 2 seconds.

- EXACTLY 2 seconds: The substrate’s surface tension is the dyne level of the tested solution.

*Always retest using a new cotton-swab (when applicable), in a clean area of the test-substrate.

Color

Dyne test products are available in colors ranging from light and dark blue to red and purple. ASTM-D2578 specifies a particular blue coloring agent and its maximum concentration level to ensure compliance with required wetting tension fluid standards. While alternative color options or highly pigmented solutions may offer convenience, their usage can compromise the integrity and longevity of the dyne test product.

Permanence of the Line

Customers often ask if the dyne fluid line should hold indefinitely when the dyne level matches that of the substrate. The simple answer is no. The line of fluid drawn during a surface tension test using dyne pens or solution will react in one of three ways, each representing a different test result:

- The dyne solution will bead up, meaning the level of the substrate is lower than that of the solution being used for the test;

- The dyne solution will hold for more than 2 seconds, meaning the dyne level of the substrate is higher than that of the solution being used for the test;

- The dyne solution will hold for exactly 2 seconds, meaning the dyne level of the substrate is the same level of the solution being used for the test.

So, if the line holds indefinitely, or for longer than the 2-second mark, it tells the user that the substrate is higher than the solution being used for the test. It is possible that the line may remain beyond the 2-second mark due to an excessive concentration of dye. In such cases, we recommend conducting the test with an alternative pen

or solution, as the surplus dye has the potential to compromise the integrity of the solution.

Pen-Tip Style

There are two types of pen tip applicators most commonly available: Felt-tip and valve-tip. The felt-tip applicator is similar to a magic marker and ensures a consistent flow of liquid on a substrate for ease of use and accuracy. The valve-style tip is similar to a bingo dauber, where the tip is depressed on the substrate to open the valve and allow solution to flood the tip. This style is more prone to uneven or excessive liquid application, which can cause erroneous readings.

Expiry Period

The two primary chemicals used in dyne solution evaporate at very different rates, leading to disproportionate changes in concentration levels over time and, consequently, alterations in the measured dyne level. Exposure to environmental factors or utilization beyond the stated expiration date – which is four-six months per industry standards – can also result in inaccurate results and can exacerbate the aging process.

Conclusion

The need to test and control the surface tension of a substrate is evident; failure to do so can lead to significant time and financial losses, as well as compromises in quality. When relying on dyne testing to provide critical quality control measurements, it’s essential to utilize high-quality dyne test products formulated per ASTM-D2578 specifications to ensure reliable and precise test results.

About the Author

Melissa Lang, serving as Vice President at Jemmco, LLC, collaborates with converters worldwide, providing innovative and cost-effective solutions to intricate process challenges. With 25 years in business, Jemmco, LLC is a premier provider of supplies and equipment for the converting industry, including dyne test products, rollers and roller coverings, web cleaning supplies and equipment, and more.