Prevent Opening Failures of Bags and Pouches with Good Static Control

- Published: February 13, 2023

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Static control is important for operator safety, manufacturing productivity and product quality. Easy opening is one important product quality for bags and pouches. Static charges can cause opening failures, which can jam machines causing significant down time. When static charges are the root cause, good static control can prevent opening failures.

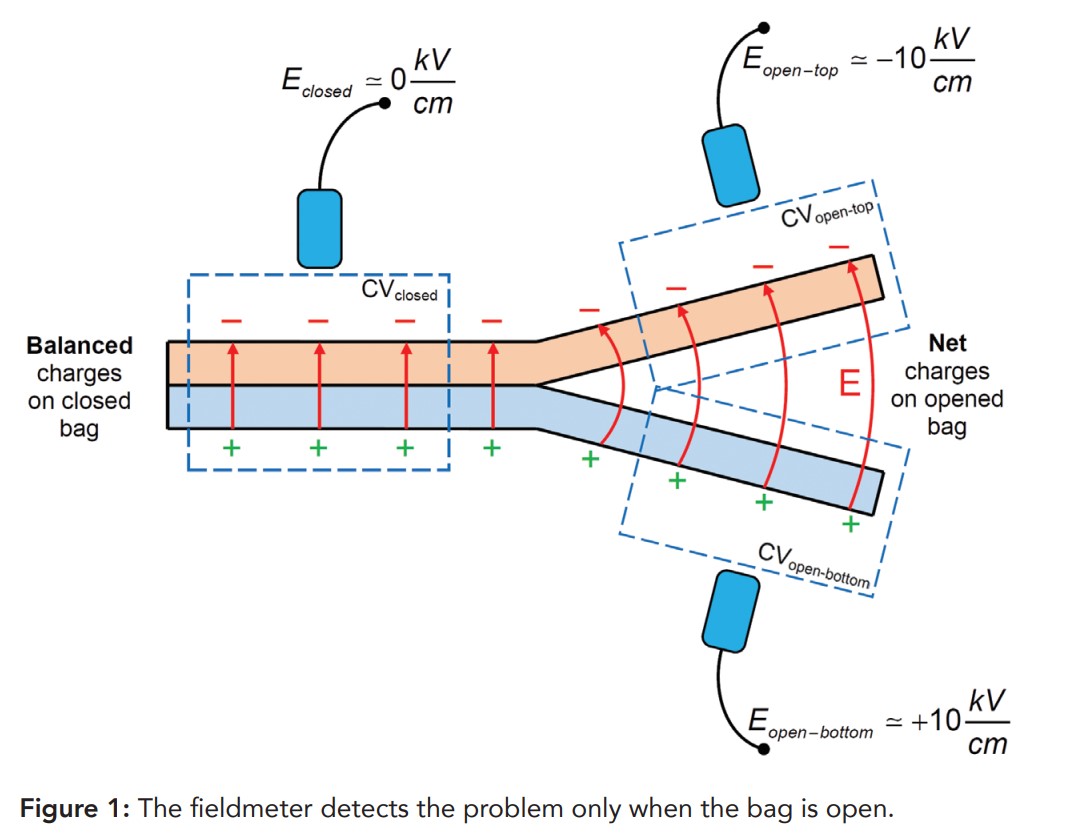

When static charges cause a bag opening failure, diagnosing the problem is difficult because the bag must be open for the fieldmeter in Figure 1 to detect the charge. When the bag is closed, fieldmeter reading Eclosed is nearly zero because the fieldmeter responds to all of the static charges inside control volume CVclosed. In this case, for every positive charge on the top of the closed bag, there is also a negative charge on the bottom of the bag. There is no net charge in CVclosed and reading Eclosed is zero.

When we take fieldmeter readings on the line when the bags or pouches are closed, we might think that there will be no problem opening the bags. However, the top of the bag is firmly pinned to the bottom of the bag. The strong electric field across the closed bag represented by the red arrows inside CVclosed indicates the attraction of the charges.

To diagnose the problem, take a bag or pouch from the end of the line. Open the bag or trim the edges so that we can separate the top of the bag from the bottom of the bag. Opening the bag or separating the top sheet from the bottom sheet separates the static charges.

Take fieldmeter reading Eopen-top in Figure 1 on the top sheet of the open bag. Reading Eopen-top responds to all of the charges in control volume CVopen-top and the negative charges inside CVopen-top are detected by the fieldmeter. To confirm that static charges are causing opening failures, take reading Eopen-bottom in Figure 1. The polarity of reading Eopen-bottom should be opposite to Eopen-top and the magnitudes should be approximately equal. And, the top of the bag is strongly attracted to the bottom of the bag indicated by the electric field E represented by the red arrows.

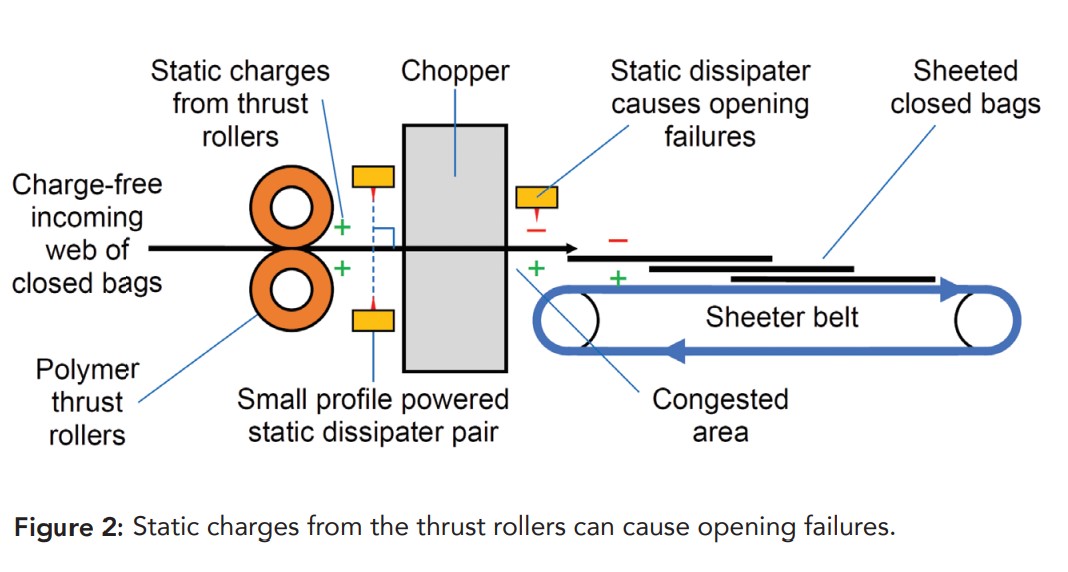

Now that we have confirmed that static charges cause the opening failure, we need to dissipate the charges to solve the problem. One common source of opening failures relates to the polymer thrust rollers in Figure 2 just before the chopper. These polymer nip rollers thrust the closed bags into the chopper. The chopper cuts across the web width and finished bags exit onto a sheet belt. The sheet belt commonly moves slower than the web speed so that the bags are partially stacked.

Polymer nip rollers can deposit large amounts of static charges on webs. Since both thrust rollers in Figure 2 have a polymer or rubber coating, static charges are deposited on both the top and bottom surfaces of the bag exiting the thrust rollers.

Often, we try to dissipate these charges with a powered static dissipater in Figure 2 exiting the chopper facing the top of the bags. Installing this static dissipater exiting the chopper can cause bag opening failures. This powered static dissipater deposits neutralizing ions only on the top of the bags exiting the chopper. The bags exiting this static dissipater look just like the closed bag in Figure 1.

Better is to install a pair of small profile static bars, some only 1/2 inch wide, exiting the thrust rollers. This pair of static dissipaters should be installed symmetrically. By this, I mean two things:

- The distance from the web to each bar must be the same; and

- A line drawn from one static bar to the other must intersect the web at a right angle.

With this static bar pair installed, the web entering the chopper is nearly charge-free. And, the static charges causing the opening failures are effectively neutralized.

This pair of small profile static dissipaters may be installed exiting the chopper. Often, this area is congested and the tail of the bag exiting the chopper is loose, which makes it hard to install a static dissipater below the bag exiting the chopper.

Bags and pouches must be easy to open. Bags and pouches must be opened to diagnose opening failures. If static charges are the root cause, installing a static dissipater exiting the chopper can make the problem worse. Instead, install a pair of static bars exiting the thrust rollers to solve the problem.

For more information, contact Kelly.Robinson@ElectrostaticAnswers.com.