Static Beat | How Do Static Wands Work?

- Published: May 18, 2012

Wound rolls of PET, BOPP, PE, and other insulators often have high levels of static that pose a shock risk to operators that cut end samples or handle the rolls. When the rolls are wound, static charges on these webs are stored inside. To avoid shocks, the wound rolls are often treated with static wands.

After treatment, the shock hazard is reduced when handling the roll. However, operators that cut samples from the roll are still at risk for static shocks. How does the static wand work? And why does the treated roll still pose a risk to operators cutting samples from the roll?

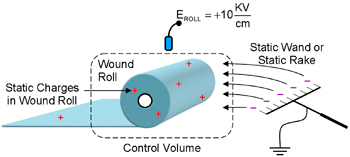

The static wand in Figure 1 is a handheld device used to treat the wound roll before it is unloaded from the winder. This static wand resembles a rake, so it is often called a static rake. Positive static charges are stored inside the roll in Figure 1.

To see how the static wand works, imagine a control volume around the wound roll. The static wand responds to the charge inside the control volume just like an electrostatic fieldmeter. The fieldmeter reading EROLL confirms that control volume contains positive static charge. The sharp needle points on the static wand generate negative charges, which are attracted to the positive charges inside the control volume.

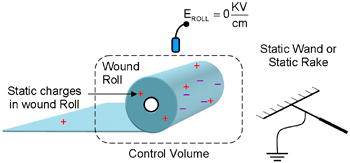

In Figure 2, the negative charges formed by the static wand move through the air and deposit on the surface of the wound roll. After the static wand treats the wound roll, the charges inside the control volume are balanced. The fieldmeter reading EROLL is zero, confirming that for every positive charge inside the wound roll, a negative charge from the static wand has been deposited on the roll surface.

However, fieldmeter reading EROLL should not be taken to mean that the wound roll is static free. PET, BOPP, PE, and many other polymers are electrically insulating. The negative charge on the roll surface cannot move through the insulating web to neutralize the positive charge inside the roll. Static charge remains inside the roll.

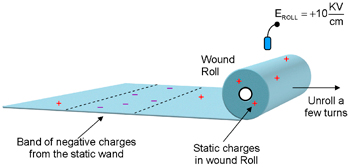

Imagine that we unload the treated roll, put it on the floor in Figure 3 and unroll it several turns. The charges from the static wand will form a band on the bottom surface of the web. Positive static remains in the wound roll. Fieldmeter reading EROLL confirms that positive static charges remain inside the wound roll. Treating the wound roll with a static wand has not neutralized the static inside the roll. In the next operation, the high static levels are visible on the treated roll after the outer lap is unwound. Check out our top-rated and highly recommended Australian Gambling Sites - www.i-casinos.net

The static wand deposits charge only on the exterior surface of the wound roll. Static charges inside the roll are not neutralized by the static wand. After the wound roll is treated with a static wand, the static charges inside remain, and they pose a shock risk when an operator uses a metal knife blade to cut though the outer layers of the roll to take an end sample. Instead of using a static wand, it is better to find sources of static charging and neutralize the charge at the source before the web is wound onto the roll.

I invite you to ask questions about this column and to suggest future topics. My email address is: Kelly.Robinson@ElectrostaticAnswers.com.

Static control expert Dr. Kelly Robinson, president of Electrostatic Answers, has 27+ years of experience in problem-solving and consulting. Contact him at 585-425-8158; kelly.robinson@electrostaticanswers.com; www.electrostaticanswers.com.