Do Not Ruin a Good Thing... Practice Good Static Control in Slitting

- Published: November 13, 2023

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Good static control is needed in slitting because this is often the last production operation before shipping to the customer. Is it OK to dissipate static only in slitting? While this seems sensible, practice good static control upstream to minimize static charges stored on the unwinding wide roll in slitting. The best that we can do in slitting is “not to ruin a good thing.”

The two over-arching static control goals are (1) to deliver static-free product to customers and (2) to minimize air-borne debris deposition on the slit web. Slitting can generate a large amount of slitter debris; particles and slivers that break away from the slit edges.

Static charges on the web attract this air-borne debris. While we can minimize contamination with good air flow management, we also need to dissipate static charges on the web entering the knives. And, we need to neutralize static charges on the winding slits.

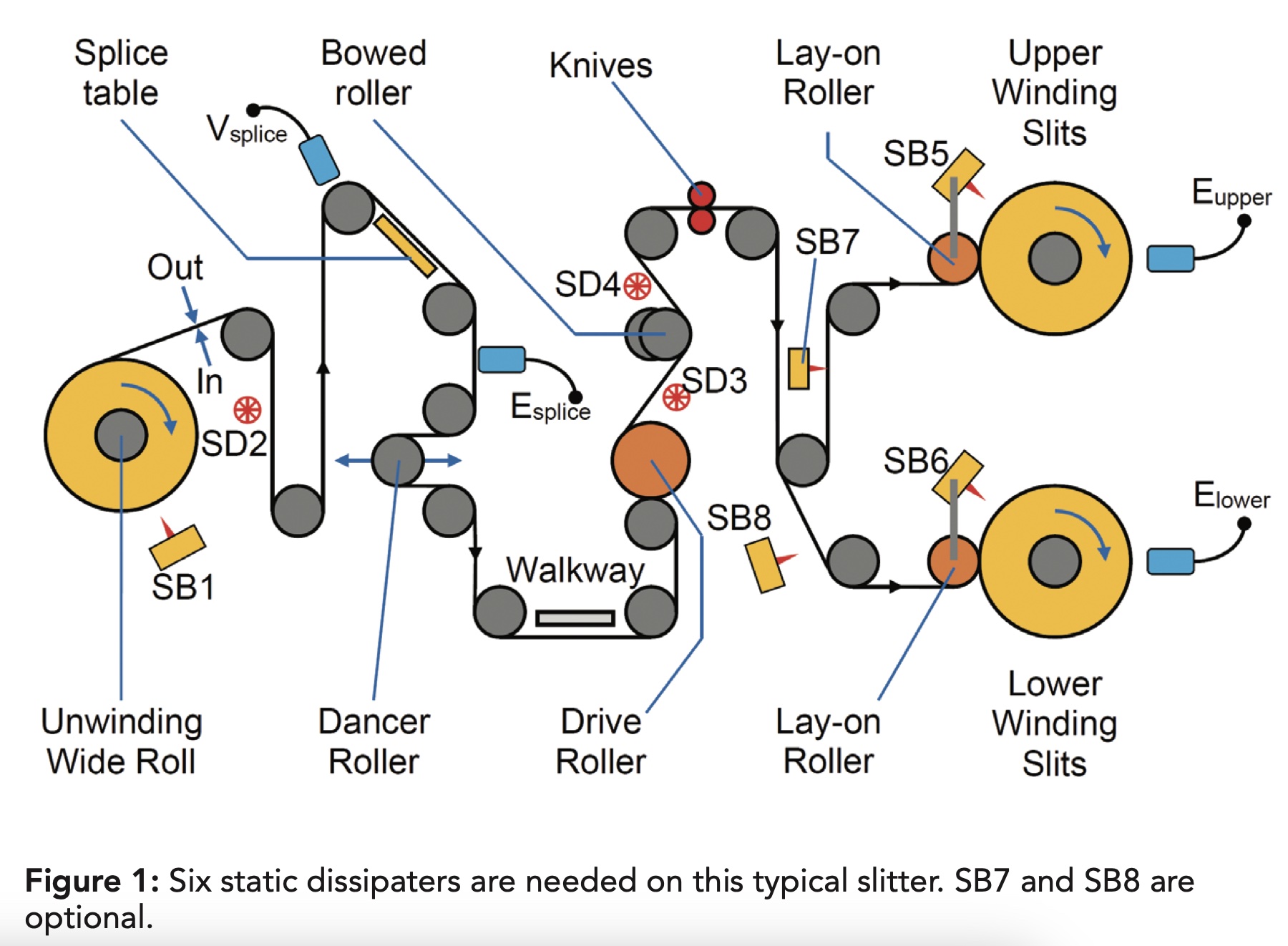

The typical slitter in Figure 1 may be divided into three zones, each having its own static control goals.

- Unwinding Wide Roll to Drive Roller – Neutralize static on the Unwinding Wide Roll.

- Drive Roller to Knives – Dissipate static charges from Drive Roller.

- Knives to Winding Slits – Neutralize static charges accumulating on Winding Slits.

In Zone 1 from the Unwinding Roll to the Drive Roller, two static dissipaters are needed to neutralize static on the web exiting an unwinding roll.1 Powered static bar SB1 in Figure 1 neutralizes static charges on the outside of the unwinding roll. Passive static dissipater (e.g., tinsel, static brush, ionizing cord) SD2 neutralizes static charges on the inside surface of the web exiting the unwinding roll. Powered static bar SB1 must be a long-range static bar because the distance from SB1 to the unwinding roll increases as the roll expires.

The web entering the Splice Table should be nearly charge-free with SB1 and SD2. Verify this by measuring the static charges on the web. Slitters are often congested making it difficult to find locations to reliably measure static charges on the web. However, usually there are measurement locations near the splice table. Use an electrostatic voltmeter to measure Vsplice to verify that powered static bar SB1 is functioning properly. Vsplice should not exceed ±0.5 volts per micron of web thickness. For example, when running 2 mil (50 um) thick polypropylene, Vsplice should not exceed ±25 volts. Use an electrostatic fieldmeter to measure Esplice to verify that passive static dissipater SD2 is functioning properly. Esplice should not exceed ±5 kV/in.

In Zone 2 from the Drive Roller to the Knives in Figure 1, two static dissipaters are needed to neutralize static from the Drive Roller and from the Bowed Roller. Passive static dissipater SD3 neutralizes static charges on the web from touching the Drive Roller. Polymer covered rollers can deposit large amounts of static charge on the web. The charge is on the web surface that touched the polymer roller. Install SD3 on the web span exiting the Drive Roller facing the web surface that touched the Drive Roller.

The Bowed Roller in Figure 1 prevents wrinkles and creases in the web entering the knives. While this is very important, bowed rollers can deposit significant amounts of static on the web surface that touches the roller. This static charge can attract slitter debris. Install passive static dissipater SD4 on the web span exiting the Bowed Roller facing the web surface that touched the roller. The web entering the knives should have only a low level of static charge. However, measuring the web charge in this area is difficult because this area of a slitter is often congested and guarded.

In Zone 3 from the Knives to the Winding Slits in Figure 1, the slits will have some static charges along the slit edges, which is difficult to neutralize. Usually, installing powered static dissipaters SB5 and SB6 to neutralize static charges on the winding slits is sufficient. These static bars may be installed on the frames of the lay-on rollers so that the distance from the static bar to the surface of the winding slits remains constant. Use a mechanically strong static bar because vibrations will limit the service life. Choose a static bar having epoxy-case component rather than a bar having a plastic housing held together with screws.

Use an electrostatic fieldmeter to measure Eupper and Elower in Figure 1, which detect the static charges on the winding slits. Eupper and Elower should not exceed ±5 kV/in.

To further improve static control to minimize web contamination, install powered static bars SB7 and SB8 on the slit webs to neutralize static charges along the slit edges. Powered static bars are needed because the passive static dissipaters will not neutralize static along the slit edges.

Use good static control upstream of slitting to minimize static charges stored on the wide roll. The overarching static control goals for slitting are to deliver charge-free slits to the customer and to minimize contamination from slitter debris.

1 K. S. Robinson, “Static Control for Roll-to- Roll Manufacturing,” IEEE Transactions on Industry Applications, vol. 59, no. 1, pp. 93-103, Jan.-Feb. 2023

About the Author

Dr. Kelly Robinson writes on static issues occurring in converting processes. Robinson founded Electrostatic Answers, has 40-plus years’ experience in industrial problem solving and was named Top Manufacturing Consulting Services Provider 2023 by Managing MFG. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..