Non-Contact Laser Gauges Pave the Way for Higher Accuracy Length and Speed Measurements at Converting Plants

- Published: September 30, 2021

Precision speed and length measurements are critical for controlling manufacturing production costs and improving process control.

By Jerome Dapore, Technical Product Manager at NDC Technologies

More than ever before, converters are being pressured to deliver higher quality products faster while continuously reducing production costs in order to remain economically competitive. But this is not so easy if you're using a contact-type measurement system to control the length and speed of web-based products. A contact gauge with inaccuracies as much as 2 percent can cost your organization a significant amount of money in unnecessary expense due to product give-away, waste, maintenance and system downtime.

This has led manufacturers to look at non-contact laser measurement techniques to accurately monitor the length and speed of products in converting applications involving continuous length measurement, differential speed control, cut-to-length control and product positioning, to name a few. Non-contact laser measurement technology is enabling converters to realize real production gains by significantly reducing measurement errors and improving process control.

Non-contact length and speed measurement offers numerous quality, process efficiency and financial advantages.

Demanding production environments pose real measurement challenges

Depending on the application, converting plant environments can be very tough on measurement devices used to control processing operations. Currently, most length and speed measurements are made using contact methods such as tachometers and wheel/roller encoders. All contact length and speed measurements are indirect measurements relying on physical contact and friction between the product surface and another surface which turns an encoder that increments a counter. Length is calculated from the amount of rotation of the contact wheel as measured by an encoder. However, contact wheel encoder systems by their very nature have several fundamental flaws that make them prone to measurement errors. These include:

- The amount of slippage or jitter between the wheel and the measurement surface;

- Day-to-day wear of the contact wheel, causing the radius to change; and

- Build-up of product material, debris or other material between the wheel and product.

Also, many products are marked, scored or creased by the contact of a measurement device, possibly resulting in damaged product.

In general, most contact wheel encoder systems provide a length error of 0.5 percent or higher; greater than 1.0 percent error is common. A contact encoder attached to the drive roller or capturing pulses off the drive roller encoder has the same problems. From a quality standpoint, contact tachometers have the potential to mark the product, thereby creating a defect. From a maintenance perspective, contact measurement systems require periodic calibration and service. The ideal length and speed measurement technique is a non-contact method that directly measures the material length and speed.

Typical contact length and speed measurement methods are problematic.

Non-contact approach eliminates errors

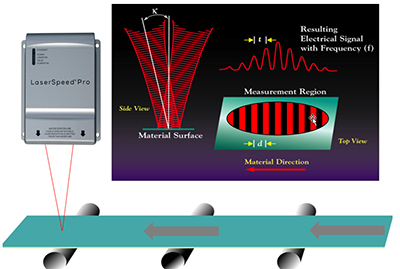

Non-contact length and speed measurement systems avoid the measurement pitfalls encountered by mechanical contact systems. For example, non-contact encoders use a unique, laser-based measurement technique that does not make contact with the product. How it works is that the laser velocimeter encoder projects a unique laser-based pattern on the surface of the product. As the product moves, light is scattered back to the instrument. This information is translated into product speed and pulses are produced to determine the product length. In many cases, non-contact laser encoders can measure any type of product, regardless of color, shape or texture. Length and speed measurements are captured with high accuracy and repeatability.

Non-contact laser encoders, such as NDC Technologies’ LaserSpeed Pro, measure product length and speed with better than +/-0.03 percent accuracy and +/-0.02 percent repeatability.

Common measurement applications at converting plants

Non-contact laser encoders have been successfully used in a wide range of industries for a broad scope of length and speed measurement applications. The following illustrates some challenging length and speed applications where manufacturers were able to improve process control and realize production savings.

Continuous length at slitter/rewinder

A manufacturer of sanitary products had problems with inconsistent length measurements at the slitter/rewind station. The installed mechanical encoder wheel experienced slippage errors of up to 2.5 percent caused by lubricants on the product. The slippage errors produced a product length longer than the target length. This resulted in shipping too much product to customers. By installing the non-contact laser encoder, the manufacturer reduced the length error by greater than 2.0 percent, saved approximately $40,000 per year and realized a ROI in less than three months.

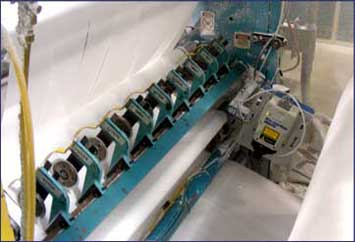

LaserSpeed Pro non-contact laser gauge at slitter/rewinder in sanitary product manufacturing plant.

Cut control in corrugated packaging

A manufacturer of corrugated boxes needed to accurately control the speed of product during normal production and “tail-out” situations. Slippage from contact encoders and "out-of-calibration" pull rolls created variances in the cut which ultimately resulted in material scrap. By using a non-contact laser encoder to accurately measure the actual board’s speed as the product enters the cutting knives, the speed signals from the unit provided the control system with precise pulse counts to control the cross cutter. This accuracy helped to significantly reduce scrap and increase product quality. The company realized savings greater than $200,000 per year.

Corrugated box plant accurately measures board speed and reduces scrap.

Control stretch and draw in paper, film and foil

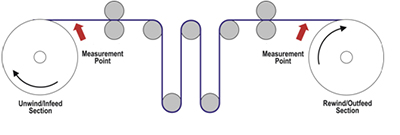

Manufacturers of non-woven, paper, film and foil products have applications where they need to draw down or stretch products to very specific and accurate thicknesses. Most manufacturers depend on the accuracy of their drive speeds or contact encoders. Products typically exhibit a certain amount of slippage on the drive roller based on texture, product composition or tension at other points on the line. A contact encoder attached to the drive roller exhibits the same problems. A contact encoder riding on the product reveals wheel wear, slippage and calibration issues. Placing one non-contact laser encoder at each critical measurement point along the line enables the manufacturer to accurately determine the amount of stretch or draw down of the product.

Placing the non-contact laser encoder at two different measurement points accurately monitors the differential speed

The future for converters looks laser bright

Converters across a spectrum of manufacturing sectors now have a high-precision measurement solution for their production needs. The advantages of non-contact laser length and speed measurement has been proven on all types of applications including continuous length, cut control and speed control, to name a few. This advanced and affordable technology eliminates the measurement errors associated with contact wheel tachometers and drive systems as a result of slippage and mechanical wear. Non-contact laser measurement gives converters the competitive edge, enabling them to control product quality while realizing significant production savings.