Treating Your Business (and Your Customers) with Corona Treatment

- Published: November 30, 2023

By Dr. Alexander Rau, Product Manager, Baldwin Technology

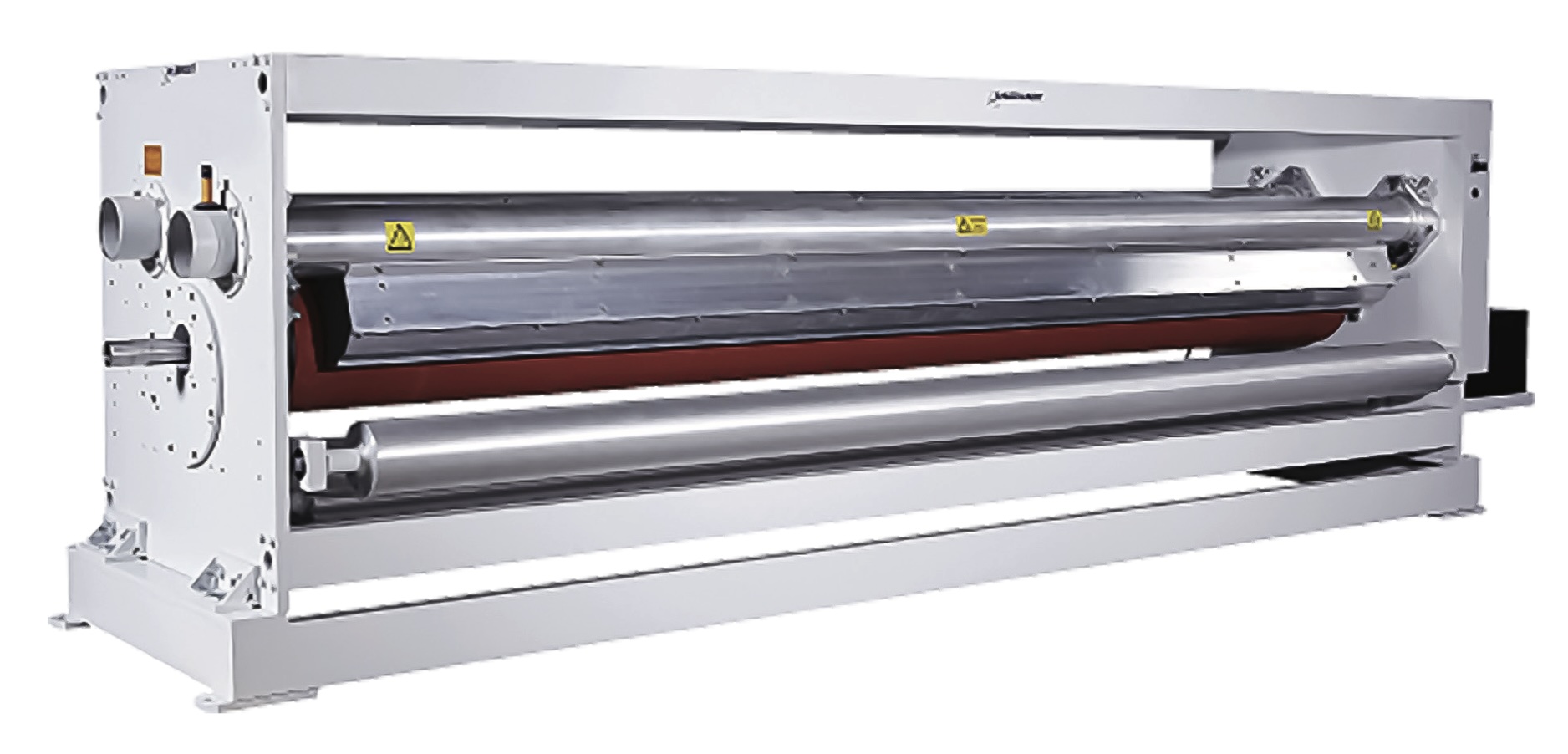

Converting and flexography benefit from corona treatment to ensure premium printed quality and optimized line speeds. Increasing the surface energy of plastic films, papers and foils means that they can be printed on or coated with exactingly uniform results and with great adhesion.

Advanced corona treatment is a prime example of how smart equipment upgrades offer cost-effective solutions to today’s most pressing challenges: Competitive pressures, labor contraction and the shifting regulatory landscape.

Competitive Pressures

Margins are small in this competitive industry. Corona treatment is allowing traditional offset printers to grow their businesses by moving into the flexible packaging space, with in-mold labeling (IML) applications top of mind. Packaging historically printed on flexo is migrating toward its being offset-printed.

The ability of corona treatment to increase surface tension and achieve high levels of adhesion for the new generation of eco-friendly inks offers convertors and printers additional competitive advantage. The high-quality graphics required by brands for IML and other flexible packaging applications wrest additional value from high-speed offset with optimized corona treatment systems.

Labor Contraction

The unemployment rate continues its descent, the workforce is contracting and a tsunami of skilled workers are retiring. Recruiting, training and retaining the next generation of workers is key. Corona treatment systems have an important role to fulfill now and in the future. The newest systems feature the easy change replacement of electrodes and rapid cleaning and removal of residues such as fiber and dust in mere seconds – with minimal technical expertise required.

The latest slate of downloadable mobile apps and simplified Human Machine Interfaces (HMI) enable easier machine operation and maintenance; complete line control can now be achieved with a few keystrokes.

Regulatory Landscape

The rapidly shifting regulatory environment – and consumer preference for more sustainably-advantaged brands and products – means that the nature of film is changing and will change further. Key components of an inclusive approach will include the inclusion of more recycled film materials or substrates that are laminated with paper. As the substrate landscape expands, Corona treatment will be even more important in order to secure unified surface quality.

From a process perspective, the latest technology removes corona treatment’s ozone emissions by converting ozone into oxygen. A catalyst bed of metal oxides, with easy monitoring and replacement of filters for optimum catalyst protection, purifies the air. Good for the environment overall and for employees alike.

Conclusion

The industry is facing a trio of challenges as we head into 2024: Tight margins, labor contractions and a regulatory landscape favoring more sustainable approaches. Corona treatment is one way to literally treat your business and your customers to a scalable, ROI-friendly solution that addresses these important concerns.

About the Author

Dr. Alexander Rau is product manager at Baldwin Technology for corona, plasma and spray coating systems. He brings 20 years of experience in understanding surface technology for plastic, metal and textiles.