Modern Drying and Curing

- Published: September 19, 2024

Pioneering Advances in UV to LED Conversion, Chemistry Transitions and Sustainable Practices

By Chris Davis, Head of Sales-Web and Industrial, IST America

In the fast-evolving landscape of industrial printing and web converting, the drying and curing process remains pivotal. It's not just about "setting" inks, coatings and adhesives but about achieving the optimal crosslinking or chemical conversion that ensures durability, vibrancy and efficiency.

As we navigate the future of this industry, three major trends have emerged: The transition from traditional UV to LED curing systems, the ongoing shift in ink and coating chemistries to align with LED capabilities and the increasing focus on sustainability. Let's delve into these transformative trends shaping modern drying and curing technologies.

Transitioning from UV to LED Curing

Traditional UV curing systems have long been the backbone of industrial printing and converting processes. However, the shift toward UV LED curing is gaining momentum due to its numerous advantages. LED curing systems bring a level of efficiency and precision that traditional UV systems struggle to match. The ability of UV LEDs to produce consistent output throughout their lifespan contrasts with the degradation observed in arc lamps, which start losing efficiency from the first strike.

Adopting LED technology is not just a matter of replacing light sources. It involves understanding and leveraging LEDs' different light geometries and profiles. Unlike traditional UV systems, which rely on reflectors and shutters to direct energy, LEDs emit light from a flat source, which generally makes it more susceptible to energy loss due to the distance from the source. This, however, can be compensated to some degree with optics.

Moreover, LED systems offer immediate operational benefits. They can be turned on and off instantly, eliminating the warm-up and cool-down phases required by conventional UV systems. This on-demand functionality significantly enhances production efficiency and reduces energy usage, contributing to lower operational costs and environmental impact.

Hybrid platforms, which combine UV and LED capabilities, are becoming increasingly popular. These systems allow manufacturers to retrofit their existing UV setups with LED modules, providing a versatile solution that can adapt to different production needs. This flexibility is particularly valuable as industries continue to explore the optimal applications of LED technology across various substrates and processes while retaining the ability to run UV-based inks, coatings, etc.

Evolution of Inks and Coatings Towards LED Compatibility

As LED curing technology advances, there is a corresponding shift in the formulation of inks, coatings and adhesives to align with LED curing requirements. Traditional UV inks and coatings rely on photoinitiators that react to specific UV wavelengths (absorption). However, LED curing typically operates at narrower wavelength bands (365, 385, 395, and 405 nm). These PIs are different from the UV variety and often require supporting chemistry to function similarly to the UV variant, necessitating the reformulation of these materials to ensure effective curing.

This transition is not without its challenges. The chemical complexity involved in formulating LED-compatible inks and coatings requires extensive testing and validation. However, the industry is making significant strides in this area, driven by the demand for more efficient and environmentally friendly solutions.

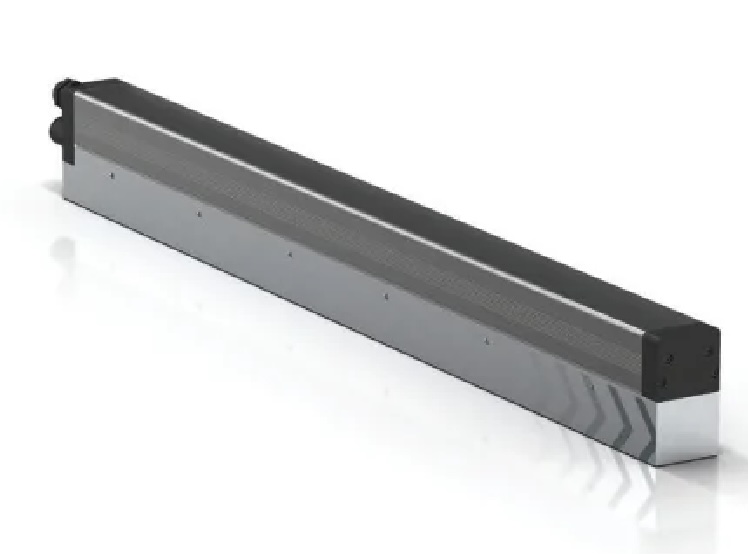

That said, innovative new UV platforms such as IST's FREEcure technology are also to be considered. Designed to provide ultra-high UVC output and eliminate the need for photoinitiators, FREEcure is a solid alternative to electron beam (EB) curing systems. It is particularly suitable for food packaging applications. This development underscores the industry's commitment to creating safer, more sustainable curing processes.

Manufacturers are increasingly investing in LED curing units for their laboratories, indicating a strong push towards developing and validating new chemistries that can take full advantage of LED technology. This investment in LED-compatible chemistries supports the transition to LED curing and opens up new possibilities for product innovation and performance enhancement.

Embracing Sustainability in Curing Technologies

Sustainability is at the forefront of modern manufacturing, and the drying and curing segment is no exception. LED curing systems inherently support sustainability goals due to their lower energy consumption and reduced environmental impact compared to traditional UV systems.

One of the key advantages of LED systems is their ability to operate at lower energy levels without compromising curing quality. Unlike UV arc lamps, which require continuous high energy to maintain the ionized gas state, LED systems can adjust their output to match the exact requirements of the curing process. This capability not only conserves energy but also extends the operational life of the equipment, reducing the frequency and cost of replacements and maintenance.

Integrating digital platforms and artificial intelligence (AI) into LED curing systems further enhances their sustainability credentials. Companies can easily capture and track key KPIs and OEE numbers, allowing for easier reporting to sustainability goals. Advanced systems leverage Al to optimize curing settings based on real-time data from ink providers. This ensures that energy usage is precisely matched to each job's curing requirements, minimizing waste and maximizing efficiency.

Conclusion

As the industrial printing and converting industries continue to evolve, transitioning from UV to LED curing, adapting ink and coating chemistries, and prioritizing sustainability are redefining the landscape of modern drying and curing technologies. These advancements not only offer operational efficiencies and cost savings but also align with the broader environmental goals of reducing energy consumption and eliminating hazardous materials.

About the Author

Chris Davis, Head of Sales-Web and Industrial, IST America, is a degreed mechanical engineer. He joined the industry in 1993, driving web press and converting equipment sales. He has contributed to numerous trade magazines and has given speaking engagements. His areas of expertise include converting and industrial radiation curing applications.