Adapting for Digital or Conventional Labels

- Published: August 12, 2024

By Mike Agness, Executive Vice President, Americas, HYBRID Software

Just by the nature of the job, there is a difference between printing different types of packaging, from labels to flexible packaging to corrugated. So, what makes label printing so unique? For starters, label printing tends towards digital.

With the availability of digital printing, as more brand extensions are entering the market or being tested, they aren't initially done in million run lengths. They're printed in much smaller quantities.

The challenge owners need to address is to look at labels from the business perspective. Digital printing of labels is here to stay. When adapting digital, at what point do they cross the tipping point for revenue and how does one make that profitable? This can't be done in a vacuum. To generate the same revenue and greater profits with smaller quantity jobs, it takes more digital jobs to reach that crossover point.

Several years ago we talked to customers about the convergence between revenue of digital to flexo jobs. While you're selling a digital job for $1,000, a traditional job on a conventional flexo press can cost the customer $5,000 to $10,000 or more. Yet practically every digital job requires the prepress department to "touch" that job.

For example, repeat jobs don't just mean pulling plates and printing again. You won't be competitive selling $1,000 jobs when every touch costs $25 to $50 in time against that revenue stream.

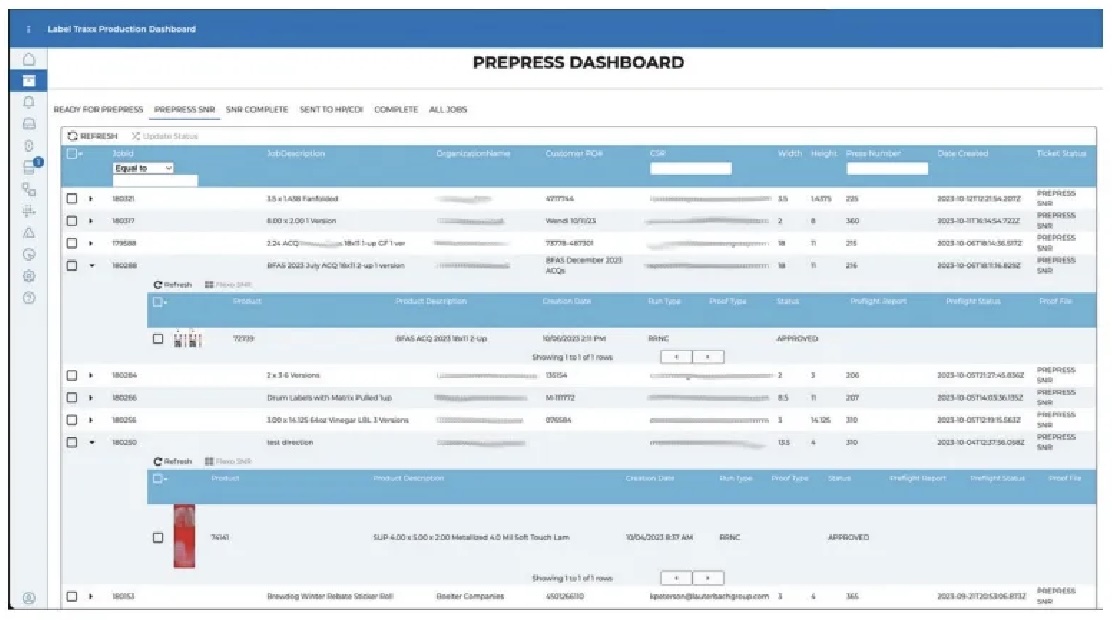

Whether digital or traditional, all these steps, except for platemaking, occur for both digital and traditional presses. Digital just accelerates the process. You have to gain efficiencies, and this comes from the assistance of software.

Digital printing can reduce consumables and time — a reduction of "spend," so to speak. While you think about the crossover revenue point, there are other variables. For example, if you print on a flexo press, you can get more ink coverage, making the label stand out more. However, this also increases ink costs and can slow down the press, adding job costs. There's a balancing act to consider.

Who knows what drupa is bringing? The industry is getting closer to digital label presses that can match or surpass the speed of some flexo presses. It will be easier to match run lengths without most of the changeover costs. However, digital ink costs will still be measurably more expensive than that of flexo, and there will still be the challenges of "feeding the monster." How do you prepare files for an extremely fast-running digital press with the least amount of touches — and the fewest changeovers of print stocks? Automating production as much as possible, from a Web2Print or MIS system, becomes almost imperative.

Fewer Ink Units, Greater Color Gamut?

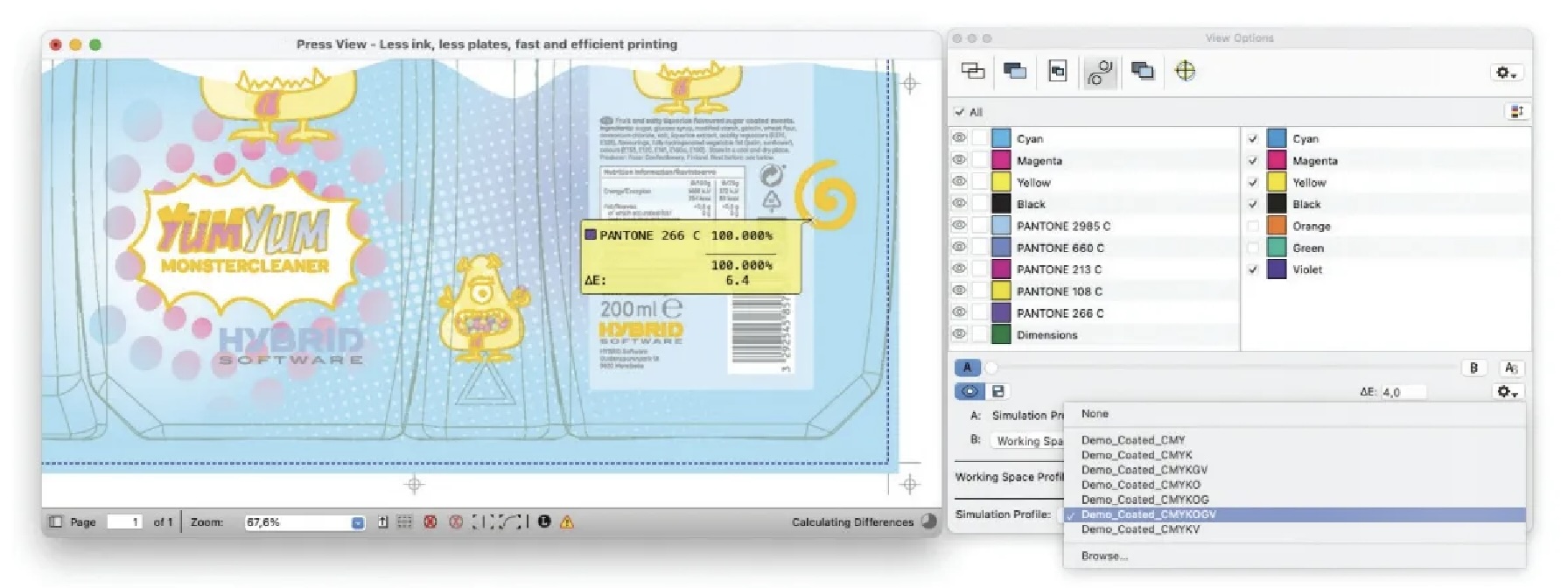

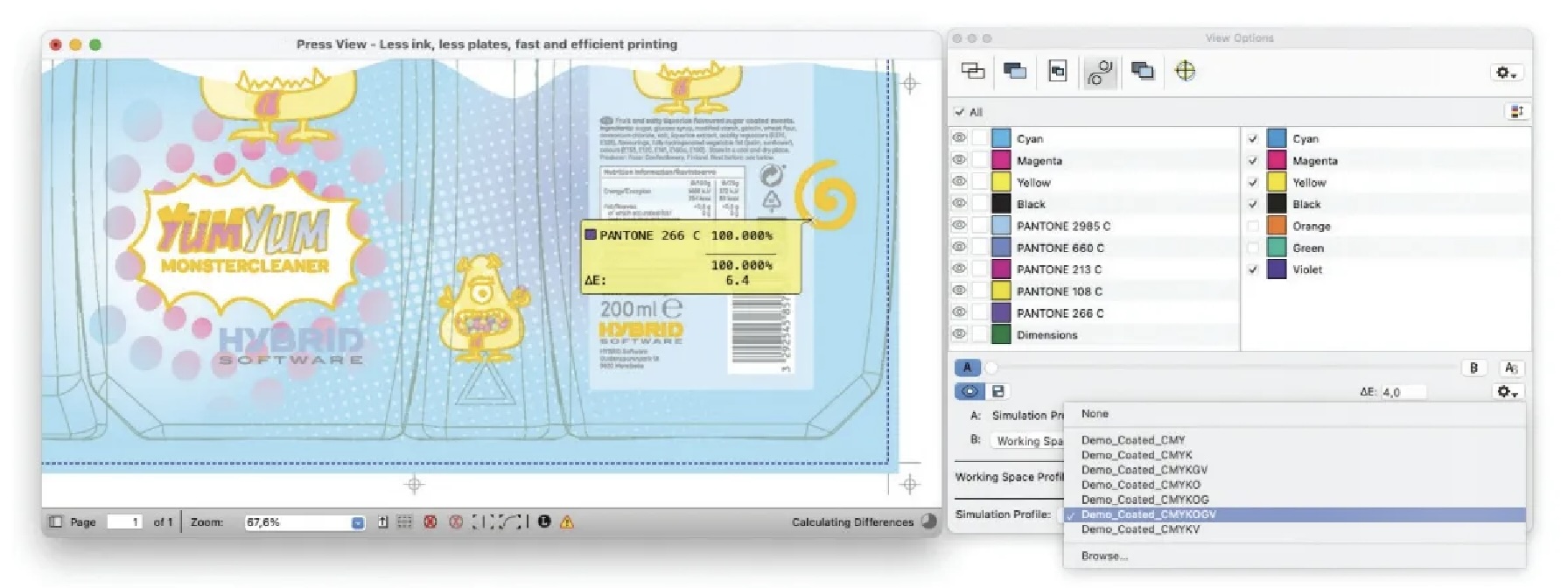

A flexo press can have as many as 10 or 12 units, making it easy to print brand colors with special inks. Times have changed, and many flexo jobs are printed with expanded gamut (an entire story on its own), but there are still color challenges.

If a label printer moves from flexo back to digital - which happens with many brand extensions — color space coverage issues can arise. Marketers need to understand that six-color ink sets, for example, can closely match the special inks that they've relied on, although depending upon the brand colors and ink set, there could be challenges. Can the brand color be printed with an acceptable variance from spectral color, and can you predict that process?

Forward thinking might suggest that it would be wise to prepare different graphic designs if you think that a brand will be going from 100,000 to 1 million labels — which most likely will not run on a digital press. If you print a new label design digitally, there will likely be some minute color differences that occur between digital and flexo/offset. If you're a new brand coming to market, you might want to invest upfront resources designing correctly for both print processes, betting that you'll be using both.[

Make Yourself Indispensable

While there are still many label shops, there has also been a lot of consolidation. Smaller shops — those who haven't merged or been acquired — are being pressured to differentiate themselves with value-added products and services, like specialty finishing or exceptional online customer service. A lot of vendors are happy to help you upgrade.

This means even more pressure on production workflow software. A good software system can help create the layers - the inks, the separations and where they should be specified - and also provide 3D proofing to help visualize the finished product. The 3D prototype are also needed for purchase that is not transitioning to the "Add to Cart" button on an e-tail website.

Each Label Can Be Unique

Each Label Can Be Unique

We haven't even addressed variable data. What if labels must be serialized, for example? Even flexo jobs often rely on a separate digital unit to assist. Be ready to have software that can prepare this quickly for digital presses. The best way is to rely on the prepress software to do the work rather than the digital press front end. It allows the digital front end to stay dedicated to keeping the digital press running all the time, while relying on the robust prepress workstation to do all the heavy versioning work. That's much faster.

Sustainable Substrates

Particularly in Canada and in some states, there is a greater emphasis on the impact of label material on the environment. For example, in Canada shrink sleeves are essentially banned. So, print stocks need to be eco-friendly, recyclable-friendly or sustainable. The pressure is on stock, inks, recycling, streams and related issues — affecting costs.

Single-use plastics are being considered a thing of the past. How do we replace the labels? Maybe there isn't a label. Everything could be printed just like aluminum cans. Could this mean a trend to direct-to-object printing in the future? One thing is certain. It will most certainly be digital.

The differences between traditional and digital label printing comes down to the inherent nuances presented by the different types of jobs and determining which process makes sense. Good production and accounting departments who are able to cut through the complications presented by many print variables will make the digital vs. conventional decision much easier. The more you can adapt, the better off you'll be.

About the Author

Mike Agness, HYBRID Software executive vice president, Americas and previously vice president of sales for HYBRID North America joined HYBRID Software in 2011 after a long career at Pitman Company and Agfa Corp. He brings a strong blend of technical and sales experience to HYBRID Software and its customers. He can be reached at mikea@hybridsoftware.com.