Precision Anilox are the Foundation of the Printing Process

- Published: June 13, 2022

By Joe Settanni, Vice President of Sales, Apex International/North America

In printing, the anilox is a method used to provide a measured amount of ink to a flexographic printing plate. An anilox can be a solid cylinder or sleeve and is coated with an industrial ceramic. The surface is then laser engraved creating millions of very fine dimples knows as cells.

These cylinders are normally engraved to a specific LPI (lines per inch) and a volume capacity, referred to as BCM (billion cubic microns). Alternatively, they can be engraved to various other geometries, including open cell structures.

No matter the LPI and BCM configuration of the anilox, it is fair to say these precise printing instruments are the foundation of the printing process. As such, proper handling of your anilox will ensure longevity of the roll itself and can ultimately play a part in reducing costly printing faults, scrap materials and downtime.

A consistently produced anilox, holding very tight volume tolerances, can certainly contribute to faster make-readies and, perhaps more importantly, consistent results. As the industry trend of production run lengths continue to get shorter and shorter, and as graphics continue to become more challenging for the converter, having these fine printing instruments manufactured consistently is only the beginning. Ultimately, the care one takes with these instruments determines how long those consistent results will continue.

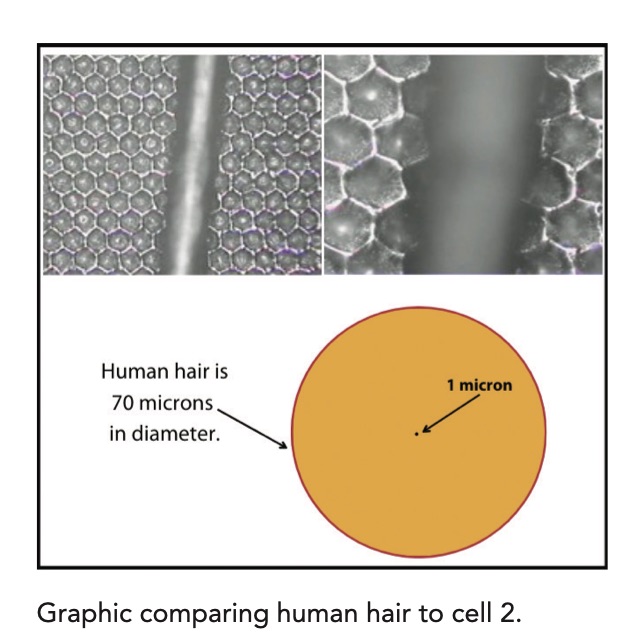

If we start by understanding just how fine these engravings are and how the smallest area of damage can affect the performance of the roll (and ultimately the print result itself), we can perhaps understand how important handling is.

For example, the image shows an engraving of 600 LPI and has a cell opening of approximately 36 microns. Compare this to a single human hair laid across it at 70 microns. As we zoom in, we can see how much of an area of this anilox is affected. Notice the rows of cells impacted by this blemish. Can we imagine what this will look like on the printed result?

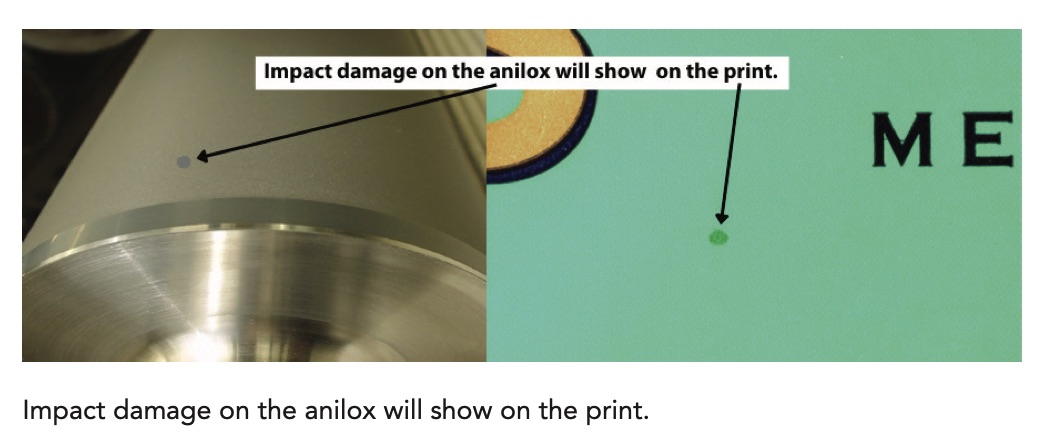

Knowing how sensitive the anilox is and having seen an anilox under magnification, it is easier to understand how many cells can be affected in a seemingly small area of damage. With that in mind, it is extremely important to minimize impact damage to an anilox.

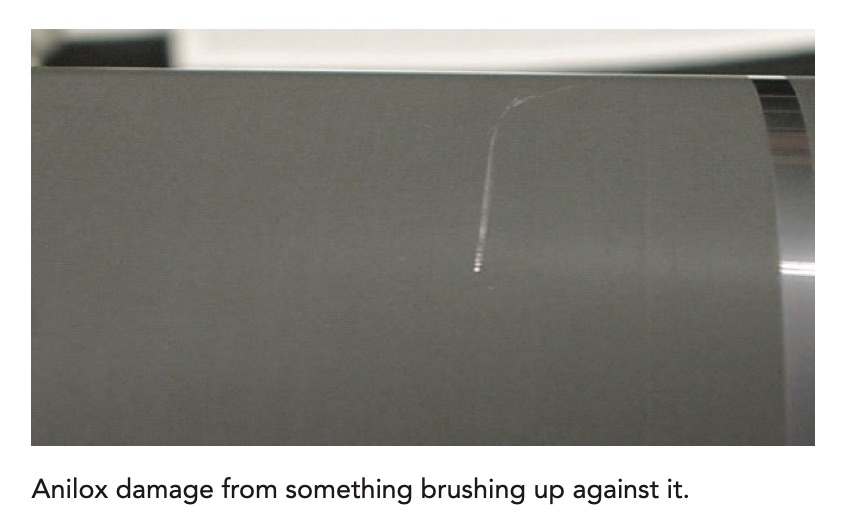

Although industrial ceramic is indeed very hard, it can be damaged easily by impact. Common causes of damage on an anilox occur while loading, storing or cleaning the anilox roll by scraping it against other equipment, jewelry (rings), belt buckles, buttons, cleanup supplies, etc.

Whenever possible, we want to keep such items away from anilox handling or storage in order to avoid this type of contact. This is an example of something as simple as brushing up against another piece of equipment or possibly a belt buckle.

The more obvious impact damage is simply dropping something, say a wrench, onto the surface of the roll. Again, although appearing to be a very small area of the roll impacted, you can see what will result in each repeat of the final print.

As with any precision device, maintenance and cleaning also play an important part in longevity and performance of the anilox. It is important to understand, regardless of the ink system (water-based, UV or solvent), to never let ink dry on the surface of the anilox itself.

There are many deep cleaning systems on the market today, however, for daily cleaning a stainless-steel brush and non-corrosive cleaner are still the best recommended practice. Often, rolls that are not clean, or possibly plugged, can perform as if they are worn. This will certainly cause print variances and printers will find themselves chasing desired results. This adds to costly downtime and use of materials such as ink and substrate.

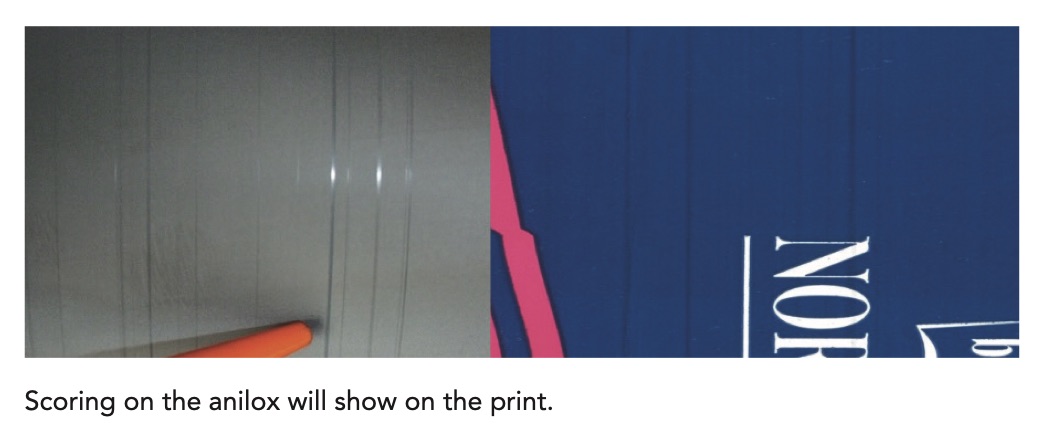

Perhaps the biggest enemy to ceramic anilox rolls is scoring. Scoring is a term that is widely used to describe a line around the anilox, which can be deeply grooved or lightly polished, and will often show in the print.

Although there are many factors that play into scoring, it is often not directly related to the anilox itself. It is caused by foreign objects (metal shavings from doctor blades, dry ink build-up, etc.) becoming lodged behind the doctor blade. Eventually, this will cause grooves in the ceramic.

It is recommended that converters systematically review all related systems (doctor blades, blade alignment, chamber alignment, end seals, etc.) to ensure that proper housekeeping, maintenance and operator training procedures are implemented and followed regularly. Keeping detailed records of anilox changes, blade changes, ink changes, activities within specific print stations and maintenance/training records will not only help identify potential problem areas, but will hopefully allow converters to repair the root cause.

Proper care of your anilox inventory can not only play a big part in achieving highest potential print results, but also help converters do so consistently. These are just a few examples of how proper care of your anilox can add to the longevity of these fine precision instruments which are so vital to our print process

About the Author

Joe Settanni has more than 25 years experience in package printing and a reputation of providing industry leading solutions. Apex International is an award-winning global manufacturer of anilox rolls, sleeves, glue sets, metering products and print maintenance solutions.