Surface Treatment: The Importance of Getting it Right

- Published: May 20, 2024

By Jan Eisby, Chief Business Officer, Vetaphone A/S, Denmark

With the growth in demand for flexible packaging predicted to continue at a rapid rate for the foreseeable future, it is important that printers and converters know exactly what substrates they are dealing with to ensure optimum productivity.

Surface treatment, usually referred to as Corona, is all about adhesion and the issues associated with non-absorbent materials, where matching the surface energy of the ink or lacquer to the substrate is essential. If they don't match, there will be problems with adhesion. Corona treatment is how we change the surface structure of the substrate to ensure good adhesion. We measure this surface energy in dynes, which is a function of watts of energy applied per square meter per minute.

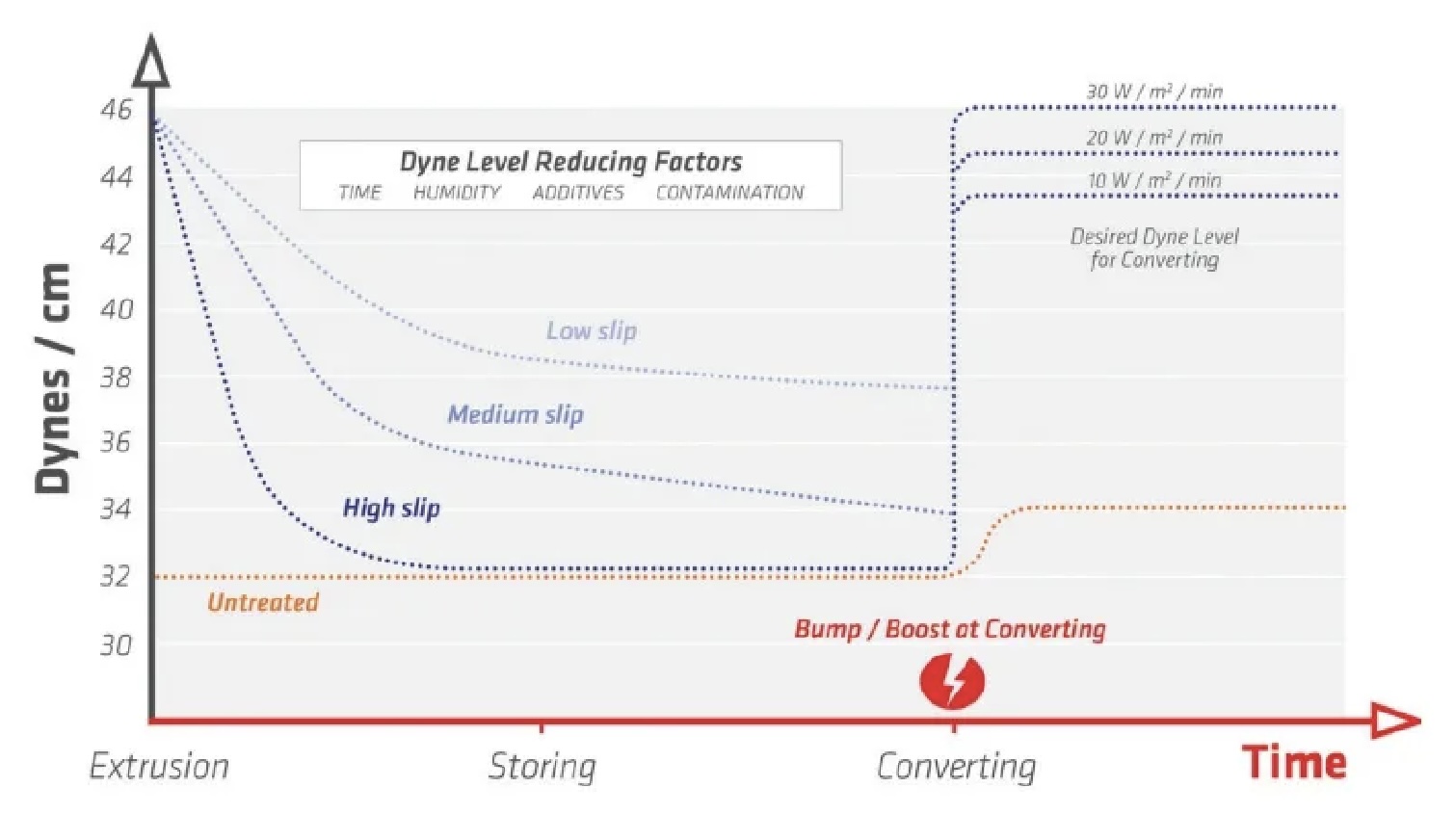

It is important to understand this because all plastic film intended for packaging is surface treated at extrusion. But films change over a period, and under different storage or transport conditions, and even from roll to roll of the same substrate because of the action of additives or contamination. That's why it's essential to test it before you use it, and if necessary, re-treat it, because different films are used for different applications and behave differently - it's a bit of a moving target!

Most modern packaging films are multi-layer because they have multi functions — like preventing contamination in food packaging or guaranteeing hygiene for medical applications. A typical coffee pack, for example, is often a multi-layer material. Corona treatment will be required on the PP surface to allow it to be printed and subsequently have an adhesive applied before laminating it to a metalized film - in every case, we need to know the dyne level and requirement of each layer before we can recommend the power required and operational production speed.

To add another variable into the equation, different rolls from the same supplier can behave differently, while supposedly the same material from a different supplier can pose even bigger problems. Typically, rolls of a particular film that vary significantly in price will do the same in terms of performance. Lower purchase price normally indicates the need for more power to reach the correct dyne value and a lower running speed, or both. As with much in life, you get what you pay for! But, of course, you need to know this information in advance, and that's why testing is so important because it can be the difference between being able to run at 1000 ft/min or 100 ft/min with the effect that has on the profitability of the job.

As the inventors of Corona treatment, we have 70 years of data going back to the original patent, so it's likely that we have tested and analyzed most combinations of ink, lacquer and substrate that the packaging sector has ever used — and this information is an invaluable reference point for customers who are experiencing problems or are looking to experiment and develop new products and applications. This is why we say that it is so important to know your films so that you understand "shelf-life."

The various types of plastic film that are used in today's package printing sector, whether for labels, shrink sleeves, pouches or other kinds of flexible packaging, are all non-absorbent and need to be surface treated to allow ink, lacquer or adhesive to adhere securely. As stated previously, this begins with the extrusion process, where the substrate being manufactured is Corona treated to obtain a certain dyne level - but it's what happens to this dyne level over the following days, weeks and months before the substrate is used in production that is important — that is what I'm referring to as its shelf life.

For any liquid to adhere securely to a filmic material, the relative surface energy between the two needs to be adjusted. Untreated film has very low surface energy, which is measured in dynes, so any liquid applied to it will stay on the surface in small beads. Corona treating the material to increase its dyne level will allow the liquid to adhere during the printing or converting process. This will produce packaging of high quality that is commercially saleable and significantly reduce the volume of waste produced.

But the dyne level achieved by surface treatment at extrusion is insufficient for the whole downstream production process. If you look at the stages of production involved, you can appreciate the complexity of the situation. First the film is extruded, then it is printed, then perhaps has an adhesive applied for lamination and maybe a lacquer coating before it becomes the end-product in its finished form. There is normally a time delay between each of these processes — sometimes short, sometimes long, but whichever it is, time is no friend to dyne levels, because all materials will suffer dyne decay from the instant they are surface treated.

To ensure that each process will work as intended, you need to check the dyne level of the substrate before you start. Then, check it before you print and again before you apply adhesive and again before coating. This checking even applies to the narrow web sector where many of the processes are done inline in one pass, so without any time delay. The issue here is that the behaviour of the new digital inks that are becoming increasingly popular is different from the flexo inks they are replacing, so once again we advise regular testing and checking.

The biggest time delay tends to occur between the film being extruded and when it is used for printing. This can be a matter of a few days, but more often stretches into weeks and occasionally months. So, storage of the film is critical. The problem is that substrate manufacturers do not give clear guidance on this subject in the datasheets relating to the different films they produce.

Some customers are better equipped to handle storage than others, and dyne decay is not necessarily consistent, so each case is different. It is also essential that the film was correctly surface treated at extrusion because this will have an impact on its shelf life and ability to be boost treated after storage. There are four factors involved in dyne decay during storage: Time, humidity, additives and contamination. These make up what we call the "decay profile."

In general terms, the more you have of each of the four factors, the greater the dyne decay will be. Using a dyne pen is a simple, reliable and inexpensive method of testing, especially if you compare it with the cost of attempting the next process with mis-matched surface energy levels between liquid and substrate.

To summarize, I'd say that knowing your film parameters is essential — how pure is it, how many ppm of additive does it have, what is its granulation? These are all key elements, so you really need to master the decay profile or go for "JIT" production where storage is not an issue.

If you are storing film, keep the temperature in the 60-70 Fahrenheit range (15-20 Celsius), and the humidity between 50-60 percent. Some transport trucks are air-conditioned, which is good, and make sure you keep the rolls wrapped to keep out dust and dirt.

Finally, to understand the converting parameters, you need ink/adhesive surface tension data from your suppliers. If you then measure the film surface tension, you can use the curve profile to calculate the boost dosage needed to reach the correct dyne level at each process stage.

About the Author

As Chief Business Officer at Vetaphone A/S, Denmark, Jan Eisby helps Vetaphone offer a unique knowledge of corona and plasma technology toward the perfect surface adhesion in the film and foil packaging industry. Learn more at www.vetaphone.com.