Spectral Analysis of Color Worth the Investment

- Published: February 07, 2022

By Robert Buongiorno, President, BST North America

In the last 40-plus years, color quality demands have increased in every area of the printing industry. At one time, the best quality printing was only found on printed auto brochures, high-end jewelry and fashion brochures, and large corporation annual reports. Today we find these same demands for cereal boxes, packaging pouches and other packaging products.

In the last 40-plus years, color quality demands have increased in every area of the printing industry. At one time, the best quality printing was only found on printed auto brochures, high-end jewelry and fashion brochures, and large corporation annual reports. Today we find these same demands for cereal boxes, packaging pouches and other packaging products.

Why has this demand grown?

One theory is the influence of electronic media. Ask yourself this: What did TVs look like 20 years ago compared to today? Early computers had an amber CRT screen, then advanced to a grainy color screen. Essentially, improvements in electronics have conditioned our eyes to see color better. These expectations have caused all aspects of the printing industry to deliver better color.

In the packaging industry, delivering this quality has proven considerably more challenging than in the commercial offset industry, since our primary printing process is flexo. Unlike offset, you can’t just adjust the ink keys or the ink-water balance. While a job is on the press, all you can do is adjust the pigment strength of the ink (assuming the plate pressure is correct) and hope you haven’t missed your target.

What can we do in the flexo packaging industry to consistently deliver the quality demanded by end users? Further, how do you ensure a product printed on one press, or in one plant, will be reproduced the same on another? For the answer, we need to look to the offset side of our industry where they have been using spectral color data as part of their quality control for years.

In web offset, the spectral data is read inline and automatically adjusts ink keys to hold the color to a predetermined target.

In sheetfed offset, the data is generally read offline through sample inspection (while the press continues to run). However, some manufacturers offer inline systems, as well. In roll-to-roll flexo, we stop the press, splice out a sample, and complete a handheld analysis of the color, splice the web back together then restart the job; a cumbersome procedure that costs time and money.

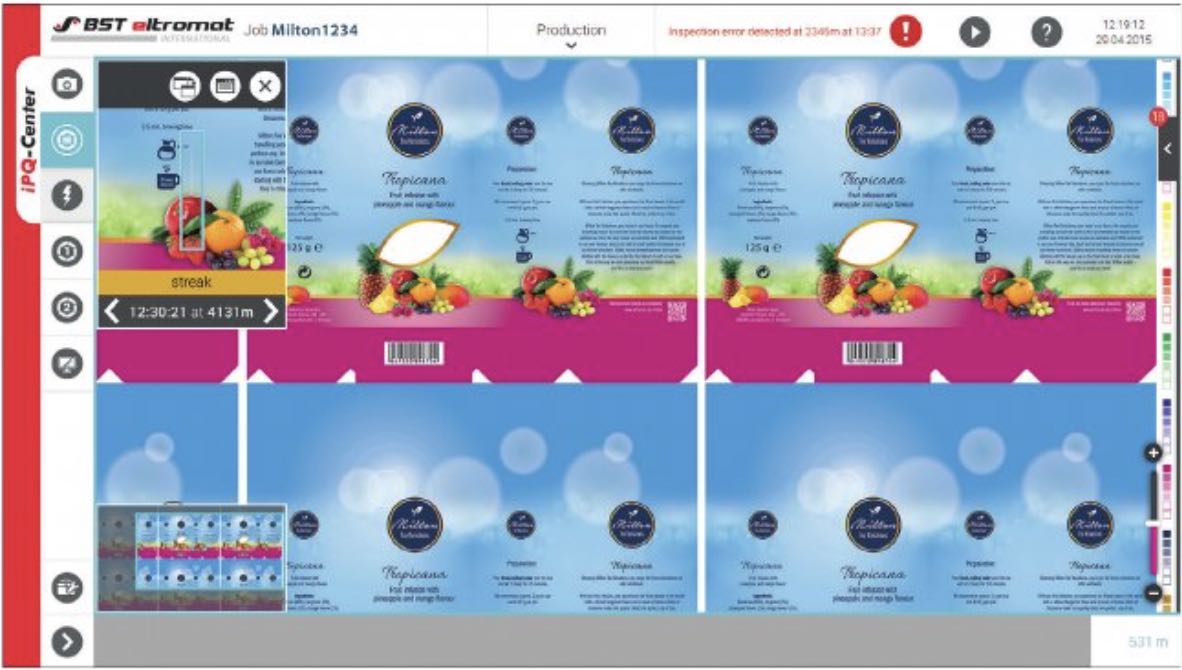

Inspection systems that offer 100 percent product inspection are common. These systems have kept a lot of bad products from going out to your customer. Unfortunately, use of 100 percent inspection with spectral analysis of color is not common.

Most (not all) packaging printers today that use inline spectral have done so because their customers have demanded the spectral color data. However, this data can be much more useful for your own plant’s quality control.

Understanding that the color you’re printing is the color the client requested, or that the color printed on press: 1) appears identical to the color printed on press, and 2), that you can do this while the press is running, saves time and money on sample analysis. Understanding what you’re printing throughout the run, not only at the beginning and finish of a roll, is the key to the future of color management.

The ability to save time, waste and provide real-time, quality color control is a major benefit to the printer. If this is the case, then why are so many packaging printers hesitant to embrace this technology? Frankly speaking, the answer is often, “We really don’t have a problem. Why should we invest the money?”

The answer is, the avoidance of one rejected job or one lost customer makes the ROI for purchasing spectral color analysis simple math. Quality control starts with a commitment to understanding data and using it to improve your processes. The biggest challenge is making the commitment and embracing the technology that is available today.

About the Author: Robert Buongiorno is president of BST North America. BST North America has been serving customers in Canada, the U.S. and Mexico for over 30 years. For more information, visit www.bst.group or www.bst-northamerica.com.