Label Tech Inc. Selects Flint Group’s nyloflex® Xpress Thermal Processor

- Published: March 08, 2019

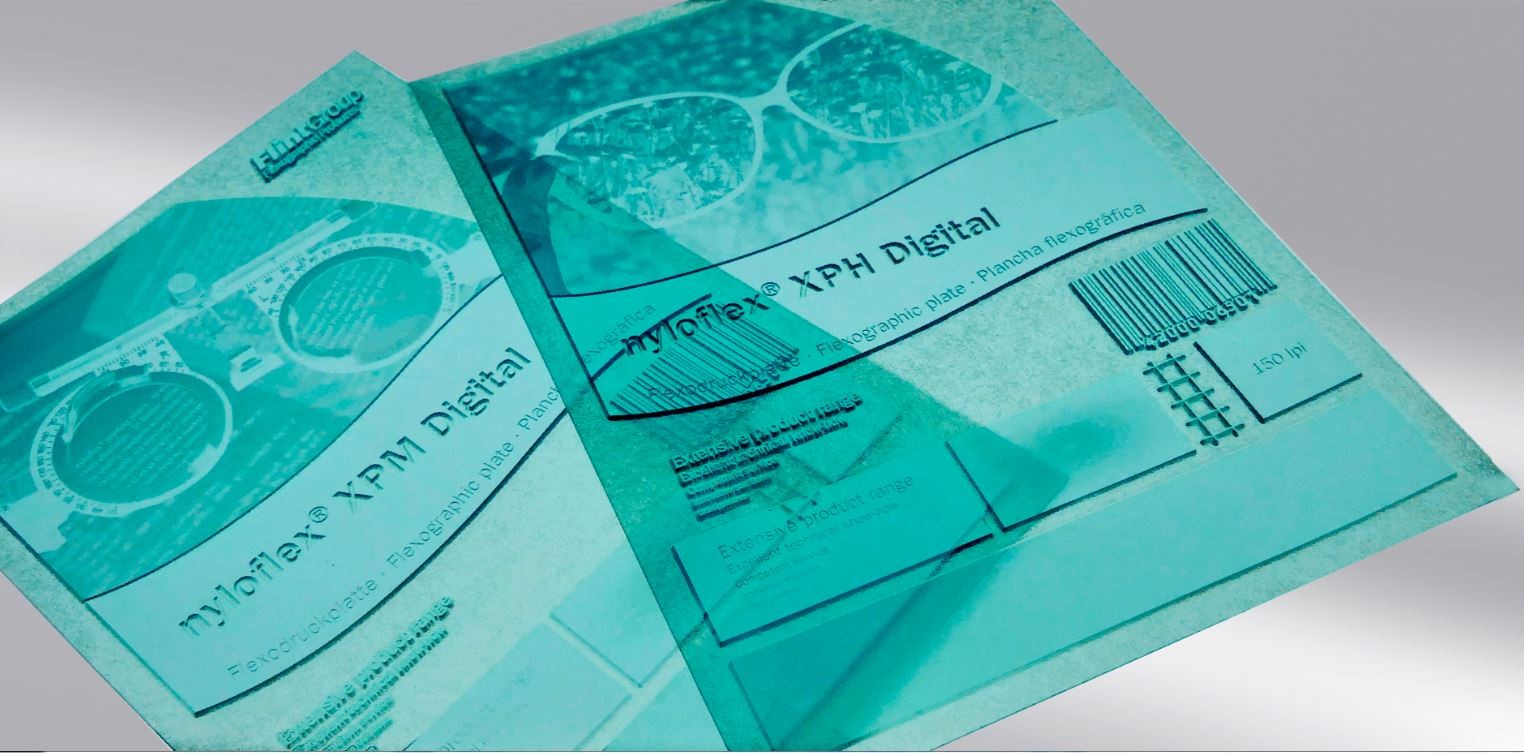

For customer-centric Label Tech, ensuring on-time deliveries with top quality products was reportedly a must-solve issue. The company therefore decided to consider a new nyloflex® Xpress Thermal Processor.

For customer-centric Label Tech, ensuring on-time deliveries with top quality products was reportedly a must-solve issue. The company therefore decided to consider a new nyloflex® Xpress Thermal Processor.

“Like any label shop, we have some very demanding deadlines. We were running into delays because we’d have an issue with the plate processor but could not get the response we needed,” said Jonathan Routhier, prepress manager at Label Tech.

The technologies team of Anderson & Vreeland (A&V), a distributor of Flint Group, and A&V regional manager, Peter Spain, recommended the nyloflex Xpress Thermal Processor.

“It is a similar concept to our older machine, but the Xpress is a modern design that uses a system of plate materials and other consumables that are meant to work together,” said Routhier. “We find the plates do a better job of transferring ink to the substrates so colors are more saturated, and there is also less plate distortion.”

W ith a fleet of flexographic presses on the shop floor, the decision to change plate processors had to be carefully thought out.

ith a fleet of flexographic presses on the shop floor, the decision to change plate processors had to be carefully thought out.

“The A&V technologies team was right there with us to answer questions and make sure we understood everything we needed to know,” said Routhier. “Then we sent in files to make sure plates we’d be producing would meet our needs. When we saw that they did; we made the decision.”

Since the new machine came online over a year ago, day-to-day advantages have reportedly shown up as better productivity along with fewer registration issues, because plates need less on-press adjusting.

For more information, visit www.labeltechinc.com.