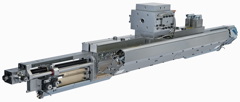

Nordson Re-Engineers Extrusion Coating Die

- Published: June 19, 2013

CHIPPEWA FALLS, WI | Nordson EDI has completely re-engineered its EPC edge bead-reducing extrusion coating die, which now reportedly yields a more robust system, is easier to operate, and cuts back on downtime for width changes and cleaning.

The EPC system is the most advanced yet available, incorporating: 1) an Autoflex VI automatic gauge profile control; 2) an Ultraflow V feedblock for multilayer coatings; 3) a new-design deckle system for rapid width adjustment and simplified removal for die cleaning; and 4) a device for quick removal of die buildup. Within the Ultraflow V feedblock are adjustable “combining planes,” located where the melt streams join the central flow channel, that operate in two modes—either automatically adjusting layer material flows or permitting fine tuning through manual adjustment.

“Nordson EDI’s next-generation EPC die eliminates the need to disassemble the deckle system for cleanouts of carbonized polymer buildup inside the lip, replacing a job that used to take an hour or an hour and a half with a simple procedure that takes just five minutes,” says chief technologist Sam G. Iuliano. “And because it is now possible to remove the entire deckle assembly as a self-contained unit, it takes half the time to completely open the die for ‘split-and-clean’ maintenance.”