Part Two of a Three-Part Series: Ultrasonic Drying of Biodegradable Molded Recycled Paper

- Published: August 26, 2024

By Gene Plavnik, President, Heat Technologies, Inc.

The first of this three-part series discussed a test program conducted by Heat Technologies, Inc's Spectra HE UltraTM drying system aimed at establishing optimized operating parameters of single-serving containers manufactured from recycled paper fiber suitable for food products with contained moisture. In the next two installments, major definitions of the related parties, the equipment, drying tests, quality control tests and data matrix utilized in this test program will be shared.

The first of this three-part series discussed a test program conducted by Heat Technologies, Inc's Spectra HE UltraTM drying system aimed at establishing optimized operating parameters of single-serving containers manufactured from recycled paper fiber suitable for food products with contained moisture. In the next two installments, major definitions of the related parties, the equipment, drying tests, quality control tests and data matrix utilized in this test program will be shared.

Major Definitions of Related Parties

- Heat Technologies, Inc. Spectra HE Ultra Drying System - Patented heat and mass transfer technology that utilizes high intensity ultrasound to increase mass transfer of the moisture by disrupting the boundary layer formed on the material, whether it is coated or not. In addition, HTT's Spectra HE Ultra technology allows accelerated drying without creating migration of solids, or "skinning" of the coating, if coating is applied.

- Curran®, is Micro-Fibrillated Cellulose Platelets (MFCP) manufactured by Cellucomp Ltd. These platelets are derived from sugar beets. Curran is used as a paper pulp additive.

- Reef® - An acrylic based water dispersion, 37 percent solids, hydrophobic, also contains Curran MFCP.

- Single-serve molded paper fiber bowls (impregnated and non-impregnated) were manufactured by Kiefel Technologies (Denmark) utilizing Natureformer KFT 90 wet thermoforming line.

- Cobb 1800 is a testing procedure that determines the amount of water absorbed into the surface by uncoated and coated paper, paperboard and corrugated fiberboard samples in a set period of time, in this particular test, 1,800 seconds. Water absorbency is measured in g/m2. The water absorbency of a material has a strong influence on the variety of converting processes. Main standards regulating Cobb tests are ISO 17025, UK standard BS EN 20535, ISO 535, US - TAPPI Standard T441 and ASTM D3285.

- Moisture Transmission and Water Vapor Transmission Rate test involves a container sealed by the material to be tested, such as a cut bottom of the molded pulp tray and containing a desiccant (e.g. calcium chloride or silica-gel). The weight gain or loss due to moisture permeation of the weight gain curve is used to calculate the MTR(WTR). The main standards regulating gravimetrical MTR (WVTR) measurements are ASTM E96-22 and ISO 2528.

Methodology of the Tests

Following are the step-by-step procedures that were used in the test program:

- Identify all measured and calculated values for the data comparison.

- Measure and calculate the area of the coating, m2.

- Accurately weigh each bowl, g.

- Coat and dry the same quantity and similar coat weights of both the impregnated and non-impregnated bowls.

- Conduct the tests at the same operating parameters for impregnated (marked as C) and non-impregnated bowls (marked as NC). That means coat weight, hot air temperature, ultrasonics, line speed, etc. are the same and are provided by the Spectra HE Ultra ultrasonic dryer.

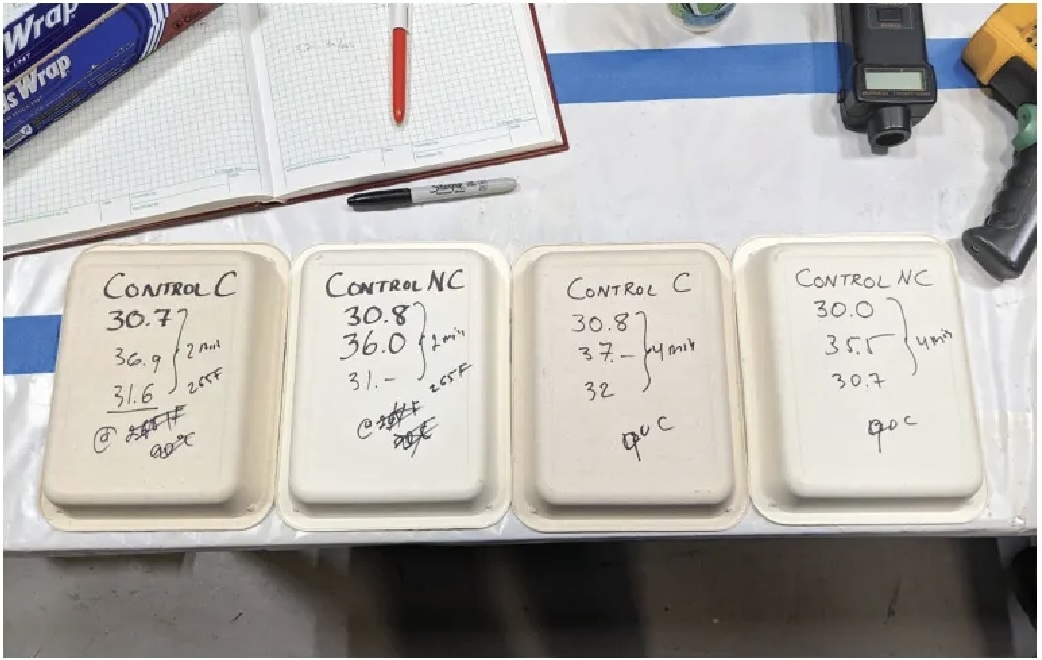

- Dry several impregnated and non-impregnated bowls (marked as CC and CNC) in the standard hot air convective laboratory oven at similar operating conditions. These are the control samples.

- Compare the control samples with the samples dried by the Spectra HE Ultra dryer.

Measured Parameters of the Bowls

- Coated area of a bowl (full inside surface), m2.

- Mass/weight of each bowl, initial weight before coating (Base Weight), g.

- Weight of each bowl after coating, g (Wet Weight).

- Difference between the base weight and wet weight, that is the weight of the coating, g.

- Weight of each bowl after drying, g.

- Temperature of the bowls after the drying (not to exceed 85C at the exit from the dryer).

Calculated Values

Calculated Values

- Base weight of each bowl, gsm.

- Area of the inside surface of a bowl to be coated, sq.m.

- Wet weight of each bowl after coating, gsm.

- Weight of the coating, gsm.

- Dry coat weight, gsm.

- Extra residual moisture re-moved/bowl is not fully dried, g and gsm.

Il. Operating Parameters of the Ultrasonic Spectra HE Ultra Dryer

- Line speed, m/min.

- Temperature of the ultrasonic air, C.

- Dwell time (drying time).

A total of 36 bowls were provided by DTI, 18 of which were impregnated with Curran platelets, and 18 were not impregnated. We chose to have 16 bowls of each type for theultrasonic drying tests and four bowls (two of each type) to be dried in the laboratory hot air high-velocity convective oven. All the bowls were coated at specific coat weights and tested.

The method of fine air spray for the coating was used. This method is simple and easy, and a controlled way to obtain the correct wet weight for each test. Watch for part three of this series, in which data matrix utilized in this test program will be shared.

About the Author

President at Heat Technologies, Gene Plavnik has more than 25 years of experience in the development, manufacturing commercialization of industrial and commercial heating and drying equipment for a variety of converting, packaging and paper industries. He is the author of nine U.S. and numerous European patents and holds a Master of Science Degree in Heat and Mass Transfer.