Migration of Fluorescent Whitening Agents from Food Packaging Made from Recycled Paper

- Published: February 29, 2004, By Etela Milanova & Bruce Sitholé, Pulp and Paper Research Inst. of Canada

Email the author(s) at: bsithole@paprican.ca

Effort to increase the utilization rate of recovered fibers implies that deinked pulps should have use in as many products as possible while still maintaining product quality and the economics of production. In North America, regulations for the use of recycled fibers in the manufacture of direct food contact packaging are still under development. Concerns exist that some contaminants may migrate from packaging into the food such as wrappers for broiled hamburgers and therefore become indirect food additives. Any company planning to produce food packaging from recycled papers must now seek a pre-market approval from regulatory agencies such as the Food and Drug Administration (FDA) and Health Canada. To obtain the approval, a petition to the agencies must be accompanied by extensive data showing that certain specified contaminants are either not present in the proposed packaging or will not migrate above the defined threshold levels. FDA guidelines recommend the use of food-simulating solvents (FSS) to generate the data on migration.

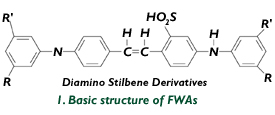

Potential contaminants in food packaging made from recycled papers are optical brighteners or fluorescent whitening agents (FWAs). Deinked pulps made from papers treated with FWAs exhibit a high degree of fluorescence that is attributed to residual FWAs still attached to the fiber. All optical brighteners used for paper whitening are compounds of the same structural type as symmetrical bis-triazinyl derivatives of 4,4'-diaminostilbene-2,2'-disulfonic acid shown in Figure 1. They have the same spectral characteristics in terms of the wavelength maxima of absorption and emission: ˜350 and ˜425 nm, respectively. These maxima positions coincide with those observed for pure cellulose that exhibits “natural” but much weaker fluorescence than FWAs. A paper sample exhibiting weak fluorescence does not necessarily indicate the presence of FWAs.

This report describes work on method development and results for the migration of FWAs from recycled paper obtained with a sensitive research-grade spectrofluorimeter and an in-house designed migration cell. Generated data and conclusions from the results were used in preparation of a petition to the FDA for approval to manufacture certain types of food-contact packaging from recycled fibers. The data are also useful as general observations about the behavior of the dyes in pulp suspensions and about the analytical chemistry of ionic FWAs.

EXPERIMENTAL

In exploratory testing of migration into FSS, paper samples underwent extraction according to FDA regulation 176.170. In all extractions of the paper sandwich samples, the solvent-to-paper ratio was 5 mL/in2. These extraction studies yield information on the presence of total FWAs present in uncoated papers.

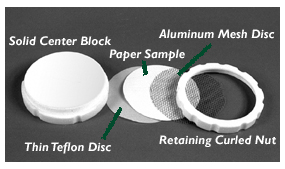

Food packaging papers are often impregnated with barrier coatings that act to prevent or minimize migration of contaminants into foods that are in contact with the coated side of the packaging. Potential migration of contaminants across such barriers is best evaluated by determining migration of compounds across the barrier coating. One way to do the evaluation is by employing one-sided extraction cells. For one-sided extractions, paper samples were cut into circular disks and inserted onto two faces of extraction blocks designed specifically for these experiments. Figure 2 shows a photograph of an extraction block with one side open to reveal its components. From the left, the figure shows a solid center, then a thin Teflon disk (to provide slippage and prevent the wrinkling of paper while tightening the nut), a paper sample, aluminum mesh disk, and retaining curled nut. The latter has a 1/4 in. extending flat lip to keep the three disks in place. Only the coated side of the paper facing the aluminum screen is in contact with solvent.

Paper samples were made in a pilot paper machine from 100% virgin kraft, 100% mixed office waste DIP, or a 50:50 mixture of the two furnishes. Papers with barrier coatings were made by coating on one side using an off-line coater. The coating materials included two types of waxes, a hot melt product, and a polyethylene coating.

INITIAL TESTS

Initial testing on migration of FWAs from recycled paper was assessed in two FSS — 8% ethanol and 95% ethanol. The solvents represent aqueous and fatty foods, respectively. Extractions were conducted at 20°C and 66°C for 30 minutes to represent short-term contact of the paper with foods under room temperature and hot-fill conditions. Test results indicated that a spiked virgin sample displayed the most migration of FWAs. The migration was greatest in 8% ethanol and at 66°C. In 95% ethanol, the extent of migration was reduced by more than two orders of magnitude. The migration patterns observed in the spiked virgin pulp were also observed in two other highly fluorescent paper samples made from 100% DIP and from 50% DIP/50% virgin except that the amounts of FWAs that migrated were lower. The migration of FWAs to the aqueous food simulants at 66°C was 4.2 ppm for paper made from 100% DIP and 2.3 ppm for paper made from 50% DIP.

Direct fluorescence measurements on paper samples before and after extraction and on extracts deposited onto filter papers were also conducted. We observed that highly fluorescent paper samples still exhibited high fluorescence intensity even after extractions under the most favorable conditions — 8% ethanol at 66°C or pure water at 121°C. This suggests two possibilities. In these batch-type extractions, FWAs tend to equilibrate between the substrate paper and solution. The fluorescence intensity of paper is not linearly related to the amount of fixed FWAs. These observations also imply that a method of estimation of amounts of FWAs that migrate into FSS based on fluorescence measurement of paper samples would be unreliable.

To explore whether the measurement sensitivity of extracts could be further enhanced in comparison with the determination of FWAs in solution, we have also measured the fluorescence of extracts deposited on filter paper. The results showed that FWAs could not be detected at below-ppm concentrations in the extracts deposited on a filter paper. The direct measurement of extracts in solution is the best method for estimating the concentration of migrated FWAs.

DISCUSSION

The aim of our extraction experiments was to assess the migration levels of FWAs from uncoated and coated paper samples made from recycled pulp. Depending on the actual results, it was then necessary to establish whether these compounds should be categorized as indirect food additives from the paper packaging for intended use. As such, they would be subject to the regulations on food additives. Exemptions from this definition were set by the final FDA rule in 1995 for such migration levels that would result in or below the “threshold” dietary concentration of 0.5 ppb of the contaminant in food. (This applies only to substances known to be non-carcinogens with the feeding dose of TD50 > 6.25 mg/kg of body weight per day). A standard amount of food for man including drinks is 3 kg. The daily intake of a contaminant should therefore be 1.5 µg.

From our data and considering the amount of packaging in possible direct contact with a single portion of food, it can be calculated that the levels of FWAs that migrate into 95% ethanol are below the threshold for all samples and conditions. If we consider about 10 in.2 of paper to be a representative area of wrapping in contact with a hamburger, the maximum amount of FWAs migrated into 100 mL of solvent from a 100% DIP sample without a barrier at 24 hours for example is 0.25 µg of fluorescent dye. The extent of migration of FWAs into nonaqueous foods as simulated by 95% ethanol would therefore be well below the threshold. Consequently, the amounts of FWAs that migrate into solvents are miniscule. Therefore, FWAs should not be categorized as indirect food additives. This implies that food packaging papers made from recycled papers do not require barrier coatings. Applying a barrier coating would nevertheless allay public fears and more importantly would improve the properties of the packaging.Recent reports indicate water-based recyclable functional barrier coatings are effective in inhibiting migration of inorganic and organic contaminants from recycled liner into packaged foods. In that work, lead and gram negative bacteria were used to simulate inorganic and organic contaminants, respectively. It is not evident from the data that these barriers would be effective for optical brighteners too.

CONCLUSION

Migration of optical brighteners as measured from their release into food-simulating solvents in contact with paper samples depends on the type of solvent used. For 95% ethanol simulating fatty foods, the migrated amounts are below the threshold value set for indirect food additives. In an aqueous solvent (at least 90% water), the migration is extensive. Among various barriers investigated, only a polyethylene-type of coating reduced migration of FWAs across the barrier.