Novel Method for Testing the Grease Resistance of Plastic-Based Dry Pet Food Packaging

- Published: March 31, 2004, By Yves Wyser, Chantal Pelletier & Jakob Lange, Nestle Research Center

Email the author(s) at:

yves.wyser@rdles.nestle.com

Application: Dry pet food packaging needing high resistance to staining from or migration of fat content requires rapid and reliable standardized tests for development and quality control purposes. New tests show high reproducibility and good correlation with field performance for a wide range of multi-wall paper bags, folding boxes, and multilayer polymeric materials.

Dry pet food packaging generally uses paper-based packaging materials such as folding boxes and multi-wall bags or multilayer polymeric materials. The application requires good resistance to migration through the packaging material of the fat contained in the product. For paper-based packaging materials, migration will cause staining of the package. With polymeric packages, a fatty film will form on the surface of the material. These are cosmetic problems, not product quality ones, but they still need attention. Judging the stain resistance of packaging materials requires reliable tests that reflect performance observed during actual package use. No commonly accepted standard test for evaluating pet food packaging materials is currently available.

The fat migration mechanism for pet food packaging is complex. Transportation and storage conditions of temperature and humidity influence migration and staining behaviour. The primary factors influencing staining are the contact pressure between pet food and packaging and the amount of available fat in the pet food. Although the recent introduction of plastic-based materials for dry pet food packaging is growing rapidly, no staining tests currently exist except long-lasting storage tests. This paper describes the development of a test method for paper- and plastic-based packaging materials. Test Method Development

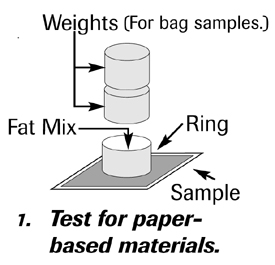

A test method exists for paper-based material. It involves placing a mixture of chicken fat and silica gel in contact with a folded 10 × 10 cm2 sample of the packaging material at 60 °C and 65% RH for 16 hours using the setup of Figure 1.

To reflect the pressure or absence of pressure acting on a packaging material from the product during storage, a pressure of approximately 7 kPa applies to materials used for fabrication of multi-wall bags, and no pressure applies to folding-box materials.

The test involves visual observation of the samples on the inner and outer sides with assessment of the resistance of a material using a scale ranging from 0 (no staining) to 4 (more than 30% of the tested surface stained). Due to significant sample-to-sample variation, the procedure tests six specimens where the final score given to a material is the worst individual result. The test conditions described above are the result of an in-depth optimization on temperature, relative humidity, time, mechanical aggressiveness, and fat composition.

With the increasing use of polymer-based materials for dry pet food packaging, a test method for this type of materials is desirable. The development aimed for a procedure lying as close as possible to the one used for paper-based materials described above. Evaluation of different types of plastic laminates used stain resistance by conventional (storage) tests. A series of plastic films of non-packaging origin was part of the preliminary testing and test development.

The test development involved selection of the visualization technique, selection of the testing substance, and selection of testing conditions. Validation of the test procedure followed.

Conclusions

This work has developed a test procedure for evaluating the grease resistance of all-plastic dry pet food packaging materials. It is similar to a recently developed test method for paper-based materials employing chicken fat as the testing substance under conditions of elevated temperature and pressure. The procedure uses thin layer chromatography plates under the sample to allow visualization of fat migration under UV light.