Static Charges: Production Mishaps and Product Misbehavior

- Published: May 27, 2024

By Matt Fyffe, VP and General Manager, Meech

Reducing downtime and maximizing productivity is a key aim for any converter, but the generation of static on production lines poses a major threat to this. With today's high-speed webs, fast-paced operations and a variety of lightweight materials being processed, it's important to understand why this phenomenon happens, and how to prevent it from impacting on business operations.

In many cases static charges will slowly decrease over a period of time, but in fast-moving business environments this is less than ideal. Some materials, such as plastic, have very high resistivities which allows them to maintain static charges for long periods of time.

Static charges are generated when an external force causes an electrical charge to move from one material to another, leaving one positively charged and the other negatively charged. If one of the materials is conductive, it won't hold the charge, but if the material is non-conductive, the charge is unable to move across the surface, creating a static "pool" of electrical charges.

The size of the charge is determined by the force of the friction, speed, pressure and separation, with increased force and faster processes leading to larger charges. The type of material involved, humidity levels in the facility, repetition of actions (friction or separation, for example), and changes in temperature can all influence the generation and maintenance of a static charge.

The impact of uncontrolled static can result in distorted finished products, out of register printed products or damaged extruded films — this can lead to increased product rejections and wastage. Machinery on the production line can also be affected

— dust attraction can lead to blockages — increasing downtime and maintenance costs. These issues are of particular significance when product cleanliness is essential to the end use for the web material: Food packaging for example, or packaging for medical supplies.

Static control technology has advanced rapidly in recent years and the latest static control and web cleaning systems play a vital role in ensuring that converters have fluid and uninterrupted production.

Static Control Solutions

Active static control provides the most effective means of neutralizing charges. This technology uses ionization, or ionized air, whereby a voltage is fed to an array of emitter pins mounted on an ionizing bar, creating a high-energy "cloud" of positive and negative ions. Any statically-charged surface, of either polarity, passing close to the cloud is quickly neutralized.

Today's pulsed DC systems come in a variety of forms to suit short-, medium- and long-range applications. Built to last, ionization bars found across many converting lines are now more resilient to buildup and even provide feedback on their performance — in fact, the most advanced static control technology now incorporates automation, allowing operators to see the performance information of the static control devices on a local user-friendly display, such as a mobile phone, tablet, touch screen or monitor, and make instantaneous amends to the operating settings. These devices can be connected to static bar controllers, which alter the level of ionization supplied from the static bar.

While static control can help deter issues surrounding product quality and staff safety, these devices alone will not solve all problems associated with a statically charged web.

Static control devices employ high voltage AC or 'pulsed' DC to produce ionized air that creates a high-energy cloud of positive and negative ions to neutralize static electricity present on production equipment. This ensures that many potentially costly production problems are avoided.

Certain DC ionizing bars provide short, medium and long-distance static elimination, and can be installed quickly and easily onto converter's lines. The application being converted, the flexographic equipment being used and the speed that the line is moving are all factors in deciding which bar is most appropriate.

What's more, automation is being incorporated into innovations. One example is smart controls, which enable the user to remotely monitor and adjust the performance of connected equipment through a mobile phone, tablet or remote desktop. Smart controls then track equipment performance using monitoring technology, allowing the user to easily assess the ionizing performance.

It achieves this through LAN or WAN networks, which allow access to performance information at any place or time, enabling operating settings to be easily amended to ensure maximum productivity and quality of output. Remote monitoring enables operators to control, alter and adjust up to six static control devices placed across various locations, significantly speeding up production processes and improving functionality.

Web Cleaners

The introduction of effective web cleaning systems alongside static control increases productivity by reducing maintenance downtime and minimizing the waste caused by sub-quality product.

A contact cleaning system is employed mostly in the print and label printing sectors. The design of the system allows operators to see the contamination being collected on a second adhesive roll, which removes debris from the first roll that makes contact with the web surface. Due to the limited life-span of adhesive rolls, contact web cleaning may not be suitable for more heavily contaminated substrate materials.

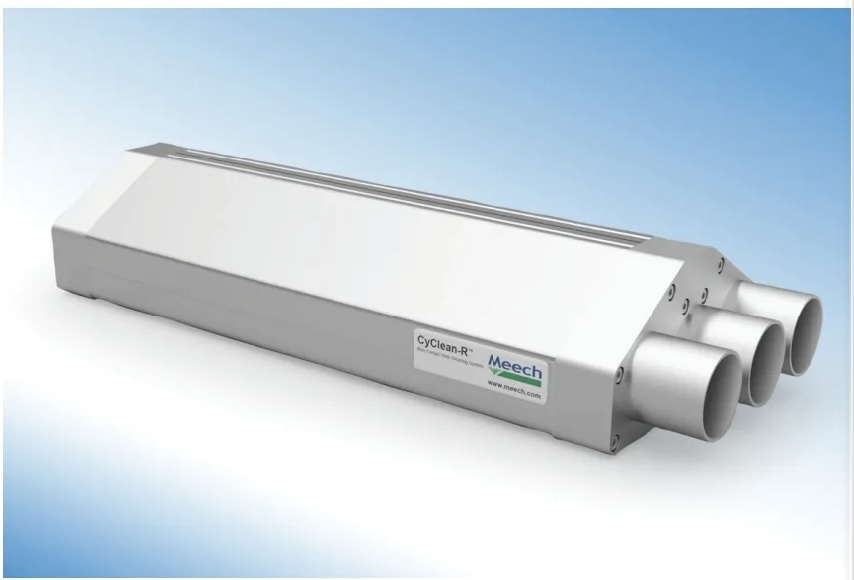

Non-contact or vacuum contact cleaners are unaffected by contamination levels. These systems are suitable for a variety of surfaces and with no consumables required for operation, running costs are reduced Certain non-contact web cleaning systems are capable of removing contamination to below 1 micron and incorporating fluid dynamic principles to deliver higher levels of cleanliness.

Using a blow-and-vacuum system, these cleaners produce a powerful blowing airflow on either side of the web to strip the boundary layer and all traces of contamination from the web's surface. The presence of vacuum airflows ensure that turbulent air is captured and subsequently removed.

The latest contact web cleaners deliver excellent surface cleaning results for the battery film manufacturing industry as well as other applications demanding exceptional cleaning standards. Featuring brush rollers, these cleaners are positioned above or below a guide roller on the web production line, to avoid all issues of tension in order to provide a high level of surface cleaning. For double-sided cleaning, two units may be used consecutively on the line.

Conclusion

Determining which types of static control and web cleaning equipment is most appropriate will require an assessment of current converting machinery and production demands. It is vital that any ionization bars and web cleaners are able to fit seamlessly into the production line, keep up the speed of production and be fitting with the budget available. Assessments should also be performed first to help determine the levels of static and contamination that are currently being generated on the line — only then can the appropriate equipment be selected.

About the Author

Matt Fyffe, VP/General Manager for Meech International, is responsible for all of Meech's operations in the USA. Having joined Meech in 1994, he has developed a vast knowledge of the plastics, packaging, automotive, medical, converting and electronics industries. He heads up the five principal sector solutions for Meech in the USA; Static Control, Web Cleaning, Energy Saving Compressed Air equipment, JetStream air knife systems and the lonRinse™ lonised air rinsing and air cleaning systems.