Airlite Plastics Expands Capacity with Davis-Standard Sheet Line

- Published: March 30, 2020

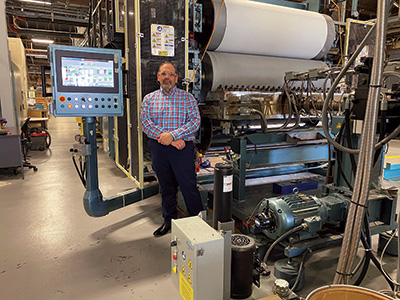

Airlite Plastics Company has reportedly expanded production capabilities at its plant in Nazareth, Penn. with a semi-custom Davis-Standard sheet line. The new line, installed in 2019, supports Airlite’s thin-gauge sheet production for products of various thicknesses and textures. This includes proprietary Orthoform® sheet used in fabricating orthotics and prosthetics, the primary market supported by the company’s Pennsylvania Division. Davis-Standard engineered the line for strict repeatability, gauge control, product consistency and low scrap, which are essential to Airlite’s highly controlled processes. Airlite operates five sheet lines at the plant, all from Davis-Standard brand companies, to support customers from the U.S. and Canada, as well as a growing international clientele.

Airlite Plastics Company has reportedly expanded production capabilities at its plant in Nazareth, Penn. with a semi-custom Davis-Standard sheet line. The new line, installed in 2019, supports Airlite’s thin-gauge sheet production for products of various thicknesses and textures. This includes proprietary Orthoform® sheet used in fabricating orthotics and prosthetics, the primary market supported by the company’s Pennsylvania Division. Davis-Standard engineered the line for strict repeatability, gauge control, product consistency and low scrap, which are essential to Airlite’s highly controlled processes. Airlite operates five sheet lines at the plant, all from Davis-Standard brand companies, to support customers from the U.S. and Canada, as well as a growing international clientele.

“Davis-Standard’s equipment has performed really well for us and that is part of the reason we are a return customer. The thing that influenced us the most is the service from Davis-Standard’s team,” said Tony Alfieri, vice president and general manager of the Pennsylvania Division, Airlite Plastics Company. “From the initial quote request through the manufacturing process and start-up, to aftersale service and support, we always get a great response. The new line is being used for our Orthoform® products and some other customized work we do in thermoforming, die-cutting, printing and lamination pplications.”

Alfieri said the right equipment combination is important because thin-gauge sheet production is challenging. His plant schedules operations around processing a unique mix of sheet thicknesses from 0.16 to .25 in. (4 to 6mm), and with different textures ranging from smooth to haircell. For example, the sheet used for Orthoform is drape-formed using a very specific resin. The ability to manufacture this type of sheet with reliability and accuracy is the company’s niche along with a “can do” mindset of taking on projects other extruders do not. Projects such as smaller batch custom colors, exotic resin blends, laminates and R&D are all part of Airlite’s service portfolio. As such, the design of the new Davis- Standard line reflects a collaborative effort between Davis-Standard and Alfieri’s team. Key components of the new line include a Thermatic® III extruder, DS-eVue control system, screen changer package, die, melt pump, and XP Express® PS series roll stand system with a unique roll configuration to ensure quality and consistency.

According to Steve DeAngelis, vice president of sheet, fiber, foam and reprocessing at Davis-Standard, “This line is a great example of how Davis-Standard is equipped to support customers who serve the medical industry. Since we are a single-source supplier, we have more control over every component, which is essential for ensuring customers like Airlite can depend on their investment. We are grateful for their business and wish them much success as they continue to grow their business.”

“Engineering and installing a complete sheet line is a huge undertaking with a lot of attention to detail. This project was smooth and on a tight schedule with Davis-Standard’s expertise benefitting us every step of the way,” added Alfieri. “Our customers choose us because we can fine-tune their process for repeatability. We focus on prioritizing the process and not pushing the pounds, which has been a key part of our success. Knowing we have the technology to make that happen is critical.”

For more information, visit www.airliteplastics.com or www.davis-standard.com/extrusion_system/sheet.