Coating Matters | The Effects of Viscoelastic Behavior, Pt. 2

- Published: April 26, 2016, By Mark Miller

Viscoelasticity is a feature of a given adhesive system that needs to be taken into account when designing a process, equipment, or application technique.

If you'd like to hear from Mark Miller's own lips rather than read his column, titled "Coating Matters | The Effects of Viscoelastic Behavior, Part 2," click on his podcast below:

{mp3}edit-effects-viscoelastic-behavior-pt2{/mp3}

In the world of hot melt adhesive coating, the engineer or operator has to understand the fundamentals of fluid dynamics and polymer extrusion. Both phenomena play a role in the complex world of hot melt adhesive coating.

When viscoelasticity controls the fluid polymer behavior, the concerns shift based off the amount of time the polymer sees stresses. If the hot melt adhesive polymer experiences stresses for a short time, the viscoelasticity is considered linear and slow deformations of the molecules occur. During these interactions, the following principles control flow:

When viscoelasticity controls the fluid polymer behavior, the concerns shift based off the amount of time the polymer sees stresses. If the hot melt adhesive polymer experiences stresses for a short time, the viscoelasticity is considered linear and slow deformations of the molecules occur. During these interactions, the following principles control flow:

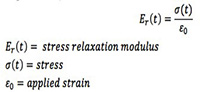

• Stress relaxation test (the same curvature at various temperatures, simply shifted by response time)

There is a measurable time it takes for the stresses to relax. These times are greater at lower temperatures.

• Time-Temperature superposition principle—Taking the stress relaxation data and superimposing onto one time plot provides the master curve described by the time-temperature superposition principle.

• Boltzmann superposition principle—The concept that deformation of a polymer can be calculated by combining all the strain responses along the path of stresses applied.

Long term stresses are measured by the following tests:

• Stress relaxation—This criteria is usually measured as the inverse of creep.

• Creep—This measurement of flow under a constant load provides strain as a function of time, temperature, and stress. Typically the power law shape of this data is material dependent and can provide insight into the flow of material at constant temperature or a set time.

These data sets can properly feed finite element analysis of flow of a polymer through an area with defined boundary conditions. The short and long term viscoelasticity help a user develop an understanding of elongational viscosity (which is the proportional factor between stress and velocity within rheological measurements) and kinetic viscosity (which is the shear rate versus viscosity data).

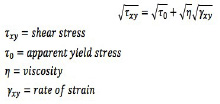

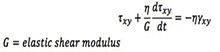

With these non-Newtonian flows, the models that provide the best approximation include the Casson and Maxwell models:

- Casson

- Maxwell

The Maxwell model is tied closely to the creep behavior, as the viscosity over elastic shear modulus is referred to as the relaxation time.

These mathematical models provide excellent correlation for internal flow of polymeric materials through set geometries. By themselves, the models do not complete the viscoelastic picture, but they provide a great starting point for finite element analysis. The questions that remain include understanding flow of the polymer melt in a three-dimensional setting of coating.

COATING

In the process of coating, the polymer that is having stress applied has its molecular chain relax and the deformation is irreversible. In some cases, this is a good thing. As in self-leveling, where the polymer flows out and forms a structure prior to curing. In other cases, the deformation can provide coating defects.

One example of the need to study polymeric flow beyond the simple test methods is roll spatter. If a Brookfield test was run on a viscoelastic material, the resultant data would be enough to understand the equipment setup for a roll coating technique, but not enough to understand flow through a pre-metered system. A viscosity versus shear rate rheological test would be enough to describe the flow characteristics through a pre-metered system, but not understand the external flow of either the pre-metered system or the roll coating technique. Previous experiments have shown that low viscosity and shear modulus does not predict roll spatter, but high elongational results from viscoelastic testing does predict roll spatter.

To describe this behavior, imagine a paint roller. Moving at the same speed, the higher molecular weight paint would splatter more than a lower molecular weight polymer paint. This is not because of the viscosity or shear modulus, but because of the decreasing elongational viscosity associated with the lower molecular weight. Higher elongational viscosity leads to large roll spatter.

Self-leveling also may be hindered by the viscoelastic nature of the polymer melt. Wanting the coating to create an even surface, the stresses placed in the polymer by the coating technique need to be allowed to relax before application to a substrate. If the polymer is coated onto the substrate in a highly stressed position, the substrate can wrinkle or retract. The key is to understand the stresses placed on the polymer within the coating system at the point of application.

DEFECTS

Coating defects associated with viscoelastic forces include curing defects that occur due to the polymer not relaxing prior to curing. This could appear as a mottled look on the coated sheet or retracted polymer against the substrate. If the viscoelastic forces override the viscous only forces, the coated surface can become fractured and look rough.

In the use of pre-metered coating techniques, care needs to be taken in the slot opening when operating the equipment with a viscoelastic polymer. The stresses involved are directly related to the volumetric flow rate of the polymer melt through the system, which in turn is controlled to the cubic power by the slot opening. Therefore, changing the lip opening by 1 unit of measure will effect the stresses on the polymer by a tremendous amount. These additional stresses will require more time for relaxation to occur post application and prior to curing.

External to the slot die, viscoelasticity can develop ribbing defects. Ribbing is a downweb pattern that appears as evenly spaced defects in the coating. In an extreme case, ribbing will present as filaments and fail to relax into a full web coating. One solution for ribbing of polymeric coatings is to adjust the attack angle of the slot die against the substrate. In essence, encouraging the polymer melt to stick to the substrate more than the metal surface of the slot die.

In addition, die swell of a viscoelastic polymer can occur external to the slot opening in pre-metered coating. This can present an edge bead to the coating or simple spreading of the polymer outside the expected coat width. Because the substrate is moving faster than the polymer is exiting the slot die, the edge effects are multiplied. To reduce this edge bead, the gap between the slot die and the substrate should be minimized. Decreasing the slot opening can have some effect (by increasing velocity), but the effect will be minimal.

CONCLUSION

Viscoelasticity is a feature of a given adhesive system that needs to be taken into account when designing a process, equipment, or application technique. The coating window for a viscoselastic fluid is more limited than the fluid with simply viscous behavior. Understanding the controlling equations will help the development of the process, design of the equipment, and implementation of the technique for the given application.

REFERENCES

- Kistler, SF, Schweizer, PM, Liquid Film Coating: Scientific Principles and Their Technological Implications. Chapman & Hall, New York (1997).

- Gutoff, EB, Cohen, ED, Kheboian, GI, Coating and Drying Defects: Troubleshooting Operating Problems. Wiley-Inter-science, New York (2006).

- Osswald, Tim A., Polymer Processing Fundamentals. Hanser Publishers, Munich (1998).

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.