Coating Matters | Patch Coating for Precision Fluid Placement, Pt. 2

- Published: October 21, 2014, By Mark Miller

If you'd like to hear from Mark Miller's own lips rather than read his column, titled "Coating Matters | Patch Coating for Precision Fluid Placement, Pt. 2," click on his podcast below:

{mp3}patch-coating-part-two-voice{/mp3}

In Part 2 of this two-part series on intermittent or patch coating, fluid control and physical movement were investigated.

EXPERIMENTAL

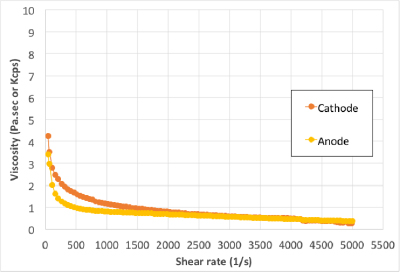

Water-base anode and NMP-based cathode slurries were utilized with aluminum and copper substrates for coating understanding. These raw materials are typical for lithium-ion battery applications. Rheological data shows shear thinning behavior for both fluids across the shear rate range experienced in slot die coating (1–5,000 sec-1).

After anode and cathode were coated, cut-outs and cross sections were taken and analyzed to determine the relative heights to the average crossweb profile. These are final dried profiles, and not wet.

The slot die was of uniform dimensions for all applications:

- Offset = 0

- Lip face (upstream and downstream) = 762 micron (0.030 in.)

- Shim thickness = 500 micron (20 mil)

- Coating gap = 25 micron (1 mil)

- Coating width = 340 mm (13.38 in.)

RESULTS AND DISCUSSION

It is damaging to the final battery cell assembly if the head, tail, or edges of coating differ in height in comparison to the bulk of the coated anode or cathode slurry. In addition to height variation, the width of the unwanted bead and the parallel nature of the coated line is important.

What was found in experimental results was that the parallel line is a function of line speed. As line speed increased, the parallel nature was less difficult to maintain. This is a combination of the wetting effects of the shear thinning fluid and the reduced pulsation at the higher line speeds.

Another important phenomena is the effect of obtaining steady-state flow conditions for the fluid prior to engaging the slot die. The critical concern is making sure the flow rate is smooth at the exit and air is not trapped in the system. In the “head” of the coating, if there is a pressure overshoot, then the fluid comes out as an increased velocity. Even if the pressure is stabilized, air in the system will allow the fluid to flow excessively. Measuring and balancing pressure within the slot die valve system improved head and tail development.

In edge effects, whether considering surface tension, film stretching, or die swell, stresses are imparted in the fluid from the slot die. These stresses develop a draw ratio D, which is defined as a ratio of the substrate speed (vsubstrate) to the fluid speed (vfluid). The edge height is taller by a factor of the draw ratio (D1/2). Proper mechanical design of the slot die for the rheology and similar fluid to substrate speed improved edge effects.

CONCLUSIONS

Intermittent coating continues to be an important and growing field in the world of slot die coating technology in general, and the flexible electronics and energy storage industries in particular.

With lithium-ion battery coating applications, the ability to meet the current production requirements for a simultaneous dual-sided, intermittent coated anode and cathode are possible in the 10-30 m/min range. The question is where the upper limit is and what advances need to be developed for higher production speeds and improved energy density.

Fluid control and physical movement were investigated for this experiment. Utilization of both seemed to create the best effects for reduced head/tail development, reduced edge bead, and improved parallel edge effects. Surface modification and vacuum were not considered for this work.

Developing a deeper understanding of raw material rheology, process limitations will provide the framework for new developments and breakthroughs in the intermittent coating industries.

REFERENCES

- Kistler, S.F., Schweizer, P.M., Liquid Film Coating: Scientific Principles and Their Technological Implications. Chapman & Hall, New York (1997).

- Gutoff, E.B., Cohen, E.D., Kheboian, G.I., Coating and Drying Defects: Troubleshooting Operating Problems. Wiley-Inter-science, New York (2006).

- Choinski, E.J., 1990, Method and apparatus for patch coating printed circuit boards, U.S. Patent 4,938,994.

- Milbourn, T.M. and J.J. Barth, 1994, Method of applying discrete coating patches to a moving web, U.S. Patent 5,360,629.

- Watanabe M., Y. Ueyama, T. Nakamura, Y. Ohana, T. Hayashi, 1998, Intermittent coating apparatus, intermittent coating method and manufacturing method of battery electrodes, and non aqueous electrolyte cell, U.S. Patent 5,824,156.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.

Mark D. Miller, author of PFFC's Coating Matters column, is a fluid coating expert with experience and knowledge in the converting industry accumulated since 1996. Mark holds a Bachelor's degree in Chemical Engineering from the Univ. of Wisconsin-Madison and a Master's degree in Polymer Science & Engineering from Lehigh Univ. and a Juris Doctor from Hamline Univ. Mark is a technical consultant and CEO of Coating Tech Service LLC. He has worked in web coating technologies and chemical manufacturing operations and is a certified Six Sigma Black Belt trained in both DMAIC and DFSS disciplines. Coating Tech Service provides process troubleshooting and project management for precision coated products. Mark has extensive process knowledge in high precision coating applications including thin film photo voltaic, Li-Ion battery, and optical systems technology. Mark has been integral to new developments and technology that minimize product waste and improve process scalability.