Z-Flute Boxes for Kitty Litter are Purr-fect

- Published: March 16, 2014

Graphic Packaging Intl. (GPI), Atlanta, GA, once again takes home the Product of the Year award, named in honor of Peter Rigney, (former publisher of Paper, Film & Foil Converter and competition supporter) in the Assn. of Intl. Metallizers, Coaters & Laminators (AIMCAL) Vacuum Metallized or Coated Product Competition. Winning now for two years straight, this time GPI showed its converting expertise with its Composipac container for Arm & Hammer's Clump & Seal Complete Odor Sealing Litter from Church & Dwight Co., Ewing, NJ, for which GPI served as converter, metallizer, substrate supplier, and designer.

Graphic Packaging Intl. (GPI), Atlanta, GA, once again takes home the Product of the Year award, named in honor of Peter Rigney, (former publisher of Paper, Film & Foil Converter and competition supporter) in the Assn. of Intl. Metallizers, Coaters & Laminators (AIMCAL) Vacuum Metallized or Coated Product Competition. Winning now for two years straight, this time GPI showed its converting expertise with its Composipac container for Arm & Hammer's Clump & Seal Complete Odor Sealing Litter from Church & Dwight Co., Ewing, NJ, for which GPI served as converter, metallizer, substrate supplier, and designer.

On March 16, 2014, GPI, along with recipients of the Sustainability Award and the Technology of the Year Award, were honored at AIMCAL's annual Management Meeting, held this year at the Arizona Biltmore, Phoenix AZ.

Purr-fect Litter Box

Graphic Packaging Intl.'s rendition of the Z-Flute kitty litter container claims to protect the interior product from oxygen and moisture, thus preventing it from clumping inside the package. For the purchaser, however, handles from Roberts Polypro, Charlotte, NC, make this box even more "purr-fect" for carrying and handling along with a perforated tabbed opening to simplify pouring.

Graphic Packaging Intl.'s rendition of the Z-Flute kitty litter container claims to protect the interior product from oxygen and moisture, thus preventing it from clumping inside the package. For the purchaser, however, handles from Roberts Polypro, Charlotte, NC, make this box even more "purr-fect" for carrying and handling along with a perforated tabbed opening to simplify pouring.

The 6.35-, 9.1-, and 12.7-kg (14-, 19/20- and 28-lb) boxes of premium Fresh Home or Multi-Cat Formula kitty litter involved three GPI facilities: design and converting in Solon, OH; metallizing in Lawrenceburg, TN; and paper-based substrates in West Monroe, LA. Toray Plastics (America), North Kingstown, RI, supplied the polyethylene terephthalate (PET) film.

The two smaller metallized Composipac Z-Flute cartons consist of metallized, reverse-printed PET laminated to heavyweight clay-coated solid unbleached sulfate (CCSUS) then Z-Flute reinforced with additional CCSUS paperboard for bulge and stacking strength. The largest carton uses the same metallized, reverse-printed PET laminated to GPI’s lightweight CCSUS, and it's used as a top sheet for a B-Flute box to create a metallized Composipac fluted box. Transparent and opaque inks reveal and obscure the metallic effects of the metallized film.

Earthy, Fresh & Flashy

The Marketing Award in the Food Packaging Category went to Celplast Metallized Products, Toronto, ON, Canada, for metallized, light-blocking low-density polyethylene (LDPE) bags for four varieties of potatoes from EarthFresh Farms. Celplast metallizes 1.25- or 1.75-mil LDPE from Tempo Plastics Ltd., Innisfil, ON, and returns it to Tempo for conversion into wicketed bags.

The Marketing Award in the Food Packaging Category went to Celplast Metallized Products, Toronto, ON, Canada, for metallized, light-blocking low-density polyethylene (LDPE) bags for four varieties of potatoes from EarthFresh Farms. Celplast metallizes 1.25- or 1.75-mil LDPE from Tempo Plastics Ltd., Innisfil, ON, and returns it to Tempo for conversion into wicketed bags.

Stripe metallizing allows consumers to view the product but blocks most of the light that typically would reach the potatoes in a standard poly bag. Eliminating light exposure is said to prevent the potatoes from turning green (and bitter) and more than triples shelf life to 21 days. Bags are punched with two parallel rows of ventilation holes and printed with bilingual product and brand information as well as alternate serving suggestions. Color coding identifies four varieties of potatoes.

Wine-Lovers Delight

No cork taint spills into a favorite wine with this VinPerfect Smartcap by VinPerfect, Napa, CA. Considered a new application for metallizing, a Technical Award in the Food Packaging Category was presented to Dunmore Corp., Bristol, PA, for metallizing and converting the oxygen-regulating closure system.

No cork taint spills into a favorite wine with this VinPerfect Smartcap by VinPerfect, Napa, CA. Considered a new application for metallizing, a Technical Award in the Food Packaging Category was presented to Dunmore Corp., Bristol, PA, for metallizing and converting the oxygen-regulating closure system.

Although wine quickly deteriorates when exposed to large amounts of oxygen, quality actually improves with exposure to minute amounts (less than 1 part/million/year). The pharmaceutical-grade elastomer/metallized PET/PET structure of the liner combines mechanical performance (more consistent sealing) with a controlled oxygen transmission rate. In fact, by varying the optical density of the metallization, liners can be tailored to provide the oxygen transfer rate needed by a particular wine. The two-film liner structure is said to provide a smoother, more uniform sealing surface than the heat-bonded multilayered barrier film cap liners typically seen in screw closures for wine.

Holography Hooks a Big One

Spiderwire Stealth Glow-Vis Braid, a premium fishing line from Pure Fishing, Spirit Lake, IA, hooks a Marketing Award in the Nonfood Packaging Category for Hazen Paper Co., Holyoke, MA. The prize recognizes Hazen's role in a metallized carton with a print-in-register custom hologram the company designed that features a radiating glowing burst with a discreet image of the spider legs, in conjunction with OlymPak Packaging & Printing, Minneapolis, Minnesota. Hazen also applied an embossable gravure coating to 48-gauge metallized polyester, embossed and metallized the film to create the hologram, laminated the film to 16-pt solid bleached sulfate (SBS) and sheeted the material into 24x36-inch sheets.

Spiderwire Stealth Glow-Vis Braid, a premium fishing line from Pure Fishing, Spirit Lake, IA, hooks a Marketing Award in the Nonfood Packaging Category for Hazen Paper Co., Holyoke, MA. The prize recognizes Hazen's role in a metallized carton with a print-in-register custom hologram the company designed that features a radiating glowing burst with a discreet image of the spider legs, in conjunction with OlymPak Packaging & Printing, Minneapolis, Minnesota. Hazen also applied an embossable gravure coating to 48-gauge metallized polyester, embossed and metallized the film to create the hologram, laminated the film to 16-pt solid bleached sulfate (SBS) and sheeted the material into 24x36-inch sheets.

OlymPak Packaging & Printing prints the sheets in register and converts the folding carton. The combination of holographic elements with registered printing is said to be unique for fishing line and a reflection of its first-of-its-kind status for a fishing line that glows above water, but not below. The carton, which consists of 100% recycled paperboard with a minimum of 35% post-consumer-recycled content, is credited with generating reorders more quickly than anticipated.

Golf Ball Package Has No Handicap

Hazen Paper captured a second Technical Award in the Nonfood Packaging Category for its role in producing three-pack folding cartons and 12-pack setup boxes for Titleist Pro V1 and Pro V1x golf balls from Titleist, Fairhaven, MA. Hazen transfer-metallized the 16-pt SBS from Clear Water Paper, Canton, GA. The transfer-metallized SBS replaces an SBS/foil lamination to achieve source reduction (95+% less aluminum), enhance recyclability and improve appearance. Actually, the brightness and reflectivity of the transfer-metallized surface reads more than 800 gloss meter units, roughly double the reading of the foil laminate. (A perfect mirror reads 1,000 units.)

Hazen Paper captured a second Technical Award in the Nonfood Packaging Category for its role in producing three-pack folding cartons and 12-pack setup boxes for Titleist Pro V1 and Pro V1x golf balls from Titleist, Fairhaven, MA. Hazen transfer-metallized the 16-pt SBS from Clear Water Paper, Canton, GA. The transfer-metallized SBS replaces an SBS/foil lamination to achieve source reduction (95+% less aluminum), enhance recyclability and improve appearance. Actually, the brightness and reflectivity of the transfer-metallized surface reads more than 800 gloss meter units, roughly double the reading of the foil laminate. (A perfect mirror reads 1,000 units.)

Transfer-metallized board is claimed to exhibit less curl than a foil or film lamination for jam-free handling on folding, gluing, and filling machinery. The package's lower aluminum content also reportedly minimizes the chance of accidentally tripping electronic security or radio frequency identification systems. The sheeted board is hot-leaf stamped and offset printed. Curtis Packaging, Sandy Hook, CT, provides converting and design.

Visual + Tactile Appeal Sells

Opalescence Go Tooth Whitening System from Ultradent Products Inc., South Jordan, UT, earned Hazen Paper another Marketing Award in the Healthcare, Cosmetics and Toiletries Packaging Category for auto-bottom folding cartons in three versions: mint, melon, and peach. A double rainbow hologram draws consumers to touch the velvet-smooth carton featuring round die-cut windows to mimic the bubbles found in the product’s active ingredient, hydrogen peroxide.

Opalescence Go Tooth Whitening System from Ultradent Products Inc., South Jordan, UT, earned Hazen Paper another Marketing Award in the Healthcare, Cosmetics and Toiletries Packaging Category for auto-bottom folding cartons in three versions: mint, melon, and peach. A double rainbow hologram draws consumers to touch the velvet-smooth carton featuring round die-cut windows to mimic the bubbles found in the product’s active ingredient, hydrogen peroxide.

Hazen Paper, working in conjunction with broker Henderson Specialty Paper LLC, Anaheim, CA, served as metallizer and converter, metallizing Ultracure acrylic-coated Double Rainbow Holographic film and laminating it to the coated side of 0.018-caliper SBS. International Paper Box, Salt Lake City, UT, served as package designer and contract packager.

Masculine Attraction

Hazen Paper won yet another award in the Healthcare, Cosmetics and Toiletries Packaging Category for Technical superiority for Gucci Pour Homme and Made to Measure gift sets from Procter & Gamble Co., Cincinnati, OH. Hazen supplied Ultracure acrylic silver 48-gauge metallized polyester and laminated it to the coated side of 80# litho paper.

Hazen Paper won yet another award in the Healthcare, Cosmetics and Toiletries Packaging Category for Technical superiority for Gucci Pour Homme and Made to Measure gift sets from Procter & Gamble Co., Cincinnati, OH. Hazen supplied Ultracure acrylic silver 48-gauge metallized polyester and laminated it to the coated side of 80# litho paper.

The film laminates well and smoothly stretches around the padded top of the Pour Homme box. McLean Packaging, Moorestown, N.J., provided package design and contract packaging services. Outstanding features of the pillow-top setup boxes included metallization, lamination, ink laydown, and a fingerprint-repelling surface.

Holographic Wizardry

Hazen Paper's holographic wizardry is commended again with the production of a litho label for a setup box designed by Warner Home Video, Burbank, CA. The 75th Anniversary Limited Edition of the Wizard of Oz earned Hazen Paper the Marketing Award in the Label: Retail Category.

Hazen Paper's holographic wizardry is commended again with the production of a litho label for a setup box designed by Warner Home Video, Burbank, CA. The 75th Anniversary Limited Edition of the Wizard of Oz earned Hazen Paper the Marketing Award in the Label: Retail Category.

Label composition features custom-registered, acrylic-lacquered 0.5-mil holographic film/80-pound coated-one-side paper with tightly registered holographic stars and rings for the top and embossed lettering for the top and side. Printing, finishing and box converting required a substrate with excellent lay-flat and stay-flat characteristics. Multi Packaging Solutions, Inc., New York, NY, converted the box at its Indianapolis, IN, facility.

Poster Rocks!

Earning yet another Marketing Award, this time in the Decorative/Display Category, is Hazen Paper, acting as metallizer and substrate supplier for a poster designed by Dwight Maddox, Atlanta, GA, for Don Miggs, Tampa, FL, and his pop/rock band miggs.

Earning yet another Marketing Award, this time in the Decorative/Display Category, is Hazen Paper, acting as metallizer and substrate supplier for a poster designed by Dwight Maddox, Atlanta, GA, for Don Miggs, Tampa, FL, and his pop/rock band miggs.

Designed to be printed in four colors plus white on an HP 7500 Indigo digital press, the poster comprises HP Indigo-compatible overlacquer/transfer-metallized 12-pt coated-two-side Hazen Burst Holojet Digital stock. This design is the first use of the Burst Holojet stock for a poster and is said to meet the band’s desire for explosive graphics and recyclable material that permits autographing because of a UV overlacquer.

Pouches Preserve Part Integrity

The Technical Award in the Industrial Category was bestowed on Technical Coating Intl., Leland, NC as converter of the Ribs Ultra Metallized laminate used by COMPtrade Technologies, GmbH, Eisenach, Germany, for two-side-sealed pouches. The pouches, which are used for long-term storage of automotive electronics and metal parts, are 48-mil PET with 3.7 optical aluminum/92-ga PET with 3.7 optical aluminum/coextrusion of PE/conductive PE/Corrosion Intercept.

The Technical Award in the Industrial Category was bestowed on Technical Coating Intl., Leland, NC as converter of the Ribs Ultra Metallized laminate used by COMPtrade Technologies, GmbH, Eisenach, Germany, for two-side-sealed pouches. The pouches, which are used for long-term storage of automotive electronics and metal parts, are 48-mil PET with 3.7 optical aluminum/92-ga PET with 3.7 optical aluminum/coextrusion of PE/conductive PE/Corrosion Intercept.

Engineered Materials, Buffalo Grove, IL, designed the package to deliver low water vapor transmission along with permanent protection against electrostatic discharge (ESD) and corrosion. The ESD protection and bronze color of the inner layer is claimed difficult to duplicate while securing authenticity. The structure enables parts suppliers to meet the 15-year storage-life requirements of the German automotive industry without repacking every few years. Filmtech, Bean Station, TN, served as metallizer; Purestat Engineered Technologies, Lewiston, ME, supplied the substrate.

Mesmerizing Light Effects

Rounding out the final Other Category with yet another Marketing Award was Hazen Paper for the cover of Gap Dream's Shine Your Light album for Burger Records, Fullerton, CA. Responsible for metallizing the Ultracure-coated, 48-gauge film/0.018-caliper SBS, Hazen Paper features a copyrighted, custom hologram with two focal points: one on the front and smaller version on the back. Stoughton Printing, City of Industry, CA, provided design and contract packaging services.

Rounding out the final Other Category with yet another Marketing Award was Hazen Paper for the cover of Gap Dream's Shine Your Light album for Burger Records, Fullerton, CA. Responsible for metallizing the Ultracure-coated, 48-gauge film/0.018-caliper SBS, Hazen Paper features a copyrighted, custom hologram with two focal points: one on the front and smaller version on the back. Stoughton Printing, City of Industry, CA, provided design and contract packaging services.

Downgauged Laminate Gets Green Credit

For the second consecutive year, UFLEX Ltd., Noida, India, parent company of AIMCAL member, Flex America Inc., Elizabethtown, KY, is recognized with the Sustainability Award. This time getting credit is a downgauged metallized laminate used by Pepsico India Holdings Pvt. Ltd. (Frito-Lay Division), Gurgaon, Haryana, India, for Lehar brand potato chips in four flavors: Tangy Tomato, Spicy Masala, Simply Salted, and Chatpateet Chatka.

Running on vertical form-fill-seal (VFFS) machines, composition of the laminate is 8-micron BOPP/rotogravure printing/8-micron LDPE/8-micron metallized BOPET/18-micron LDPE. It replaces a substantially thicker, heavier laminate of 12-micron BOPP/10-micron LDPE/12-micron metalized BOPET/20-micron LDPE. The 23% source reduction achieved with the lighter, thinner film means lower transportation costs for inbound packaging materials and outbound product shipments and fewer material roll changes on the VFFS equipment.

Running on vertical form-fill-seal (VFFS) machines, composition of the laminate is 8-micron BOPP/rotogravure printing/8-micron LDPE/8-micron metallized BOPET/18-micron LDPE. It replaces a substantially thicker, heavier laminate of 12-micron BOPP/10-micron LDPE/12-micron metalized BOPET/20-micron LDPE. The 23% source reduction achieved with the lighter, thinner film means lower transportation costs for inbound packaging materials and outbound product shipments and fewer material roll changes on the VFFS equipment.

Key to the downgauging achievement is the development of 8-micron BOPP film by UFLEX’s Flex Film subsidiary. The 8-micron film is claimed to offer the same dimensional stability and stiffness of standard 12- and 15-micron BOPP, reportedly making it suitable for printing and lamination without any negative impact on handling or registration.

Technology Award Recognizes Menges + Finalists

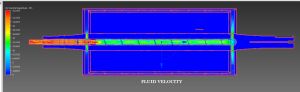

Menges Roller Co., Wauconda, IL, earned Technology of the Year Award status for its thermal modeling technology for heat-transfer rolls, called Computational Fluid Dynamic (CFD). It also was given Finalist standing in the Coating/Laminating Equipment/Accessories Category. Judges cited the ability to predict roller performance at a lower cost with CFD means the elimination of trial and error in customizing a roller to a job while also providing confidence prior to installation that a roller will function properly.

Menges Roller Co., Wauconda, IL, earned Technology of the Year Award status for its thermal modeling technology for heat-transfer rolls, called Computational Fluid Dynamic (CFD). It also was given Finalist standing in the Coating/Laminating Equipment/Accessories Category. Judges cited the ability to predict roller performance at a lower cost with CFD means the elimination of trial and error in customizing a roller to a job while also providing confidence prior to installation that a roller will function properly.

The new way to design thermal (heat-transfer or chill) rollers relies on  simulation of thermal, chemical, physical, motion, and reactive characteristics to quickly optimize performance, reduce waste and lower maintenance costs. By modeling performance, Menges reports it can predict every aspect of a roller’s behavior before it’s made. As a result, heat-transfer rollers can be guaranteed to vary less than 1 degree, thus preventing poor laminating results caused by inconsistent temperatures and missed target temperatures. In addition, the modeling is said to save time and expense by eliminating the need to rebuild rollers, tweak thermal fluid temperatures, or modify pumps.

simulation of thermal, chemical, physical, motion, and reactive characteristics to quickly optimize performance, reduce waste and lower maintenance costs. By modeling performance, Menges reports it can predict every aspect of a roller’s behavior before it’s made. As a result, heat-transfer rollers can be guaranteed to vary less than 1 degree, thus preventing poor laminating results caused by inconsistent temperatures and missed target temperatures. In addition, the modeling is said to save time and expense by eliminating the need to rebuild rollers, tweak thermal fluid temperatures, or modify pumps.

Also cited as a Finalist was Flexitube Decoseam Tubes from UFLEX in the Coated, Laminated or Metallized Product Category, featuring custom laminations with a layer of metallized film. The metallized layer is said not only to improves barrier properties, but it also can include eye-catching holographic, optically variable, or metallic effects. Reverse gravure printing of the outer layer of BOPET reportedly delivers excellent tonal reproduction while protecting the graphics from scuffing and chemical attack. The optimized laminate structure reduces wall thickness without loss of stiffness or collapsibility versus conventional multilayer tubes and seamless tubes made from extruded resins or impact-extruded metals. With a wide choice of dispensing systems and closures, the tubes are claimed suitable for a broad range of cosmetic and health-care products.

Also cited as a Finalist was Flexitube Decoseam Tubes from UFLEX in the Coated, Laminated or Metallized Product Category, featuring custom laminations with a layer of metallized film. The metallized layer is said not only to improves barrier properties, but it also can include eye-catching holographic, optically variable, or metallic effects. Reverse gravure printing of the outer layer of BOPET reportedly delivers excellent tonal reproduction while protecting the graphics from scuffing and chemical attack. The optimized laminate structure reduces wall thickness without loss of stiffness or collapsibility versus conventional multilayer tubes and seamless tubes made from extruded resins or impact-extruded metals. With a wide choice of dispensing systems and closures, the tubes are claimed suitable for a broad range of cosmetic and health-care products.

Claiming Finalist standing again is UFLEX in the Material Category for Tata Water Plus Pouch. Used for nutrient-enhanced drinking water by NourishCo Beverages Ltd., a joint venture between Tata Global Beverages, Uxbridge, West London, U.K., and PepsiCo India, Gurgaon, Haryana, India, the pouch weighs only 2.5 grams and represents an 800% source reduction compared to PET bottles typically used for water. The lighter weight also means lower inbound and outbound transportation costs and better cube utilization. At $0.033 per 200-ml pouch, the water reportedly sells for an affordable price in developing markets. The proprietary lamination runs on VFFS machines and delivers the requisite shelf life without any deterioration in organoleptic properties, meets migration and extraction standards, and suffers no degradation when exposed to intense tropical UV light.

Claiming Finalist standing again is UFLEX in the Material Category for Tata Water Plus Pouch. Used for nutrient-enhanced drinking water by NourishCo Beverages Ltd., a joint venture between Tata Global Beverages, Uxbridge, West London, U.K., and PepsiCo India, Gurgaon, Haryana, India, the pouch weighs only 2.5 grams and represents an 800% source reduction compared to PET bottles typically used for water. The lighter weight also means lower inbound and outbound transportation costs and better cube utilization. At $0.033 per 200-ml pouch, the water reportedly sells for an affordable price in developing markets. The proprietary lamination runs on VFFS machines and delivers the requisite shelf life without any deterioration in organoleptic properties, meets migration and extraction standards, and suffers no degradation when exposed to intense tropical UV light.

Wielding the Gavel

The judging panel for the 2014 Vacuum Metallized or Coated Product Competition and the Sustainability Awards Competition included Vince DiTrolio, vice president/owner of DiTrolio Flexographic Inst., Broadview, Illinois; Jeffrey T. Weber, research principal, Mondelez International Inc., (formerly Kraft Foods), Glenview, Illinois; Stan Kopecky, principal, SJK Packaging Assoc., Prospect Heights, Illinois; Yolanda Simonsis, president/editorial director, Paper, Film & Foil Converter, Chicago, Illinois; Pat Reynolds, editor-in-chief, Packaging World magazine, Chicago, Illinois; and Mark Spaulding, editor-in-chief and associate publisher, Converting Quarterly, Fort Mill, South Carolina. Randy Apperson of Finzer Roller, Des Plaines, Illinois, chairman of AIMCAL’s Awards & Competition Committee, served as moderator. The judging session was co-hosted by Simonsis and Reynolds at Packaging World’s office.

The judging panel for the 2014 Vacuum Metallized or Coated Product Competition and the Sustainability Awards Competition included Vince DiTrolio, vice president/owner of DiTrolio Flexographic Inst., Broadview, Illinois; Jeffrey T. Weber, research principal, Mondelez International Inc., (formerly Kraft Foods), Glenview, Illinois; Stan Kopecky, principal, SJK Packaging Assoc., Prospect Heights, Illinois; Yolanda Simonsis, president/editorial director, Paper, Film & Foil Converter, Chicago, Illinois; Pat Reynolds, editor-in-chief, Packaging World magazine, Chicago, Illinois; and Mark Spaulding, editor-in-chief and associate publisher, Converting Quarterly, Fort Mill, South Carolina. Randy Apperson of Finzer Roller, Des Plaines, Illinois, chairman of AIMCAL’s Awards & Competition Committee, served as moderator. The judging session was co-hosted by Simonsis and Reynolds at Packaging World’s office.

The judging panel for the 2014 Technology of the Year Competition included four well-known experts in the converting field: Dr. Charles A. Bishop of C.A. Bishop Consulting, Loughborough, U.K.; Dr. Edward D. Cohen of Edward D. Cohen Consulting, Fountain Hills, Arizona; Larry Gogolin of Gogolin Assoc., Bolton, Massachusetts; and Dr. Eldridge M. Mount of EMMOUNT Technologies, LLC, Canadaigua, New York. Craig Sheppard, executive director of AIMCAL, moderated the judging teleconference.

For more information regarding AIMCAL competitions, visit www.aimcal.org.