A Team Effort

- Published: October 01, 2006, By Edited by Deborah Donberg Associate Managing Editor

Knife Upgrade

Founded in 1990 in rural Darien, WI, Protect-all prides itself on being a team that is determined to meet new customer application demands through the modernization of its procedures, the purchase of new equipment, and the renovation of existing machinery.

The 65-employee company is divided into two focused divisions: Thermal Laminating Films and Synthetic Papers. Thermal products include standard and premium clarity laminating films as well as specialty and custom lamination products, such as curl-resistant films; printable/gluable clear, metallized, and holographic products; colored films; and a variety of textured films.

Wide-Ranging Markets

The synthetic paper division coats, laminates, slits, and sheets all types of synthetic papers. Suppliers include ITW/Valeron Strength Films (Valeron and V-Max); Daramic (Artisyn); Yupo Corp., Arjobex America (Polyart); Granwell (Polylith); and Protect-all's own PrintMaster, to name just a few.

Protect-all serves more than 500 customers worldwide, including companies that produce folders; baggage tags; credit, ID, loyalty, and gift cards; book covers; fishing and hunting licenses; parking permits; signage; maps; ski-lift passes; event tickets; wristbands; outdoor/weather-proof banners; menus; calendars; and much more.

With more than 130,000 sq ft of manufacturing and warehouse space, the company also is able to offer toll coating, laminating, slitting, and sheeting services to the trade.

Protect-all's in-house converting equipment includes a variety of slitters, rewinders, and doctor roll machinery capable of slitting from ⅜-72 in. wide, including four Camerons (now supported by GL&V USA), six Dusenberys, two REMs, and two Stanfords; a Pemco sheeter; two Egan extruder/laminators capable of poly coating and laminating widths from 24-62 in.; a custom-engineered emulsion coater/laminator running widths to 64 in.; several Stanford roll doctors; and corona treaters on nearly every machine from suppliers that include Pillar, Enercon, and Softal.

Enter New Knives

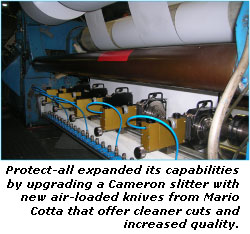

In serving such a large customer base, Protect-all makes a minimum of ten knife changes per day on many of its slitters, which operate 24 hrs/day, six days a week. To ensure the most time-efficient procedure and to deal better with typical film and synthetic paper roll profile issues, the company recently upgraded one of its Cameron slitters with Mario Cotta's knives. With the new knives, the big Cameron machine can cut all types of filmic materials ranging from a thickness of 0.5-20 mils and from 2-74 in. wide.

“Our old spring-loaded knives took workers with 30 years experience almost ten minutes to reposition each pair. With our new Mario Cotta air-loaded knives, anyone can adjust the knife within minutes,” says Steve Nimz, president of Protect-all's Print Media Div.

The Protect-all team first came across the Mario Cotta slitter knives at the 2005 CMM trade show in Chicago. After checking out other brands of knives and knife holders, they selected the Mario Cotta knives. Explains Nimz, “Mario Cotta's great service and follow-through made the purchase a very easy decision. Through the entire process, they were very accommodating, and once we received the knives, it was very easy to get our machine up and running.”

Nimz adds, “The knives have successfully expanded the range of capabilities we offer, as well as the ability to constantly meet the demands of our customers. They offer cleaner cuts and increased quality and quantity. We can run our machine longer because the knives don't require sharpening nearly as often as the old knives, which minimizes our downtime.”

Adding More Efficiency

To further increase productivity and efficiency, Protect-all also plans to upgrade its Pemco sheeter with new knives from Mario Cotta. Since the knife holders for the slitter and the sheeter then will be interchangeable, the company will be able to use the 19 new knives in both machines, further increasing productivity and efficiency.

The Protect-all team prides itself on innovative methods and equipment. Sometimes that requires expensive new equipment or challenging new technology. And sometimes it is a relatively simple upgrade to existing equipment that brings a whole new look to the process.

CONVERTER INFO:

Protect-all Inc.

109 Badger Pkwy., Darien, WI 53114

888/432-8526; protect-all.com

SUPPLIER INFO:

Mario Cotta — PFFC-ASAP 380.mariocotta-usa.com

ITW/Valeron Strength Films — PFFC-ASAP 381.valeron.com

Daramic — PFFC-ASAP 382.artisynpaper.com

Yupo Corp. — PFFC-ASAP 383.yupo.com

Arjobex America — PFFC-ASAP 384.polyart.com

Granwell — PFFC-ASAP 385.granwell.com

GL&V USA — PFFC-ASAP 386.glv.com

Dusenbery — PFFC-ASAP 387.dusenbery.com

REM Mfg. — PFFC-ASAP 388.remmfg.com

Stanford Products — PFFC-ASAP 389.stanfordproductsllc.com

Pemco — PFFC-ASAP 390.pemco.kpl.net

Egan Davis-Standard — PFFC-ASAP 391.bc-egan.com

Pillar — PFFC-ASAP 392.pillartech.com

Enercon Industries Corp. — PFFC-ASAP 393.enerconind.com

Softal Electronic — PFFC-ASAP 394.softal.de