Finding Hidden Value: Did You Know that Parts can be "Plasma Coated?"

- Published: September 05, 2024

In our industry we are always looking to improve and refine the process. It can be rewarding when we do, but often the timeline can be lengthy, capital expenditures are required, and we don't always get quite the results anticipated. Large improvement initiatives move us forward, but are we missing the small changes that can make a huge impact? Hidden gems that we don't always notice?

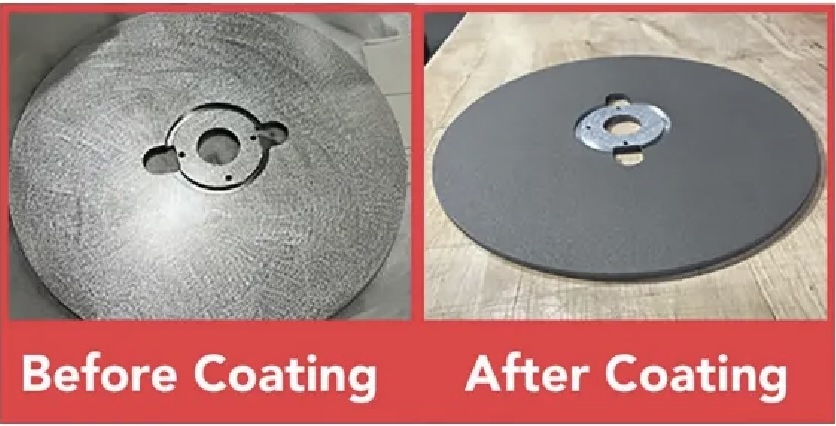

Single and Dual Layer Release and Wear Resistant Coating Systems have been used in many markets for decades. Mostly recognizable on critical rollers used in the web handling process. Regardless of the application, coating systems can provide extended life cycles and run times, performance enhancements to the end product, or solve standard web handling issues. But when we look further, these same systems can be applied to other areas of the process. Guide tables in conveying, adhesive or ink tank build up, or even interior oven parts and doors to eliminate down time and frequent cleaning.

When we look closer at smaller opportunities to improve, the payback can be realized in days or weeks. These solutions can be modest in cost, not requiring 3 signatures for a trial. However, the payback can make a real impact. Reach out to your coatings expert to take a closer look at your process outside of web processing, you might be surprised at what is discovered!

William Bradley, Vice President, Business Development

American Roller