Does Winding Generate Static?

- Published: February 26, 2024

Static levels can build on a winding roll even when the entering web is “neutral”

By Dr. Kelly Robinson, Founder, Electrostatic Answers

A winding roll can store a lot of static charge. A winding roll can store enough static charge to threaten human health. Once as I began to measure the static level on a winding roll, I was shocked by a spark that was about 20 inches long. This shock was painful and damaged my electrostatic fieldmeter. Controlling static on winding rolls is both to protect operators from dangerous shocks and to protect products that may be damaged by static sparks.

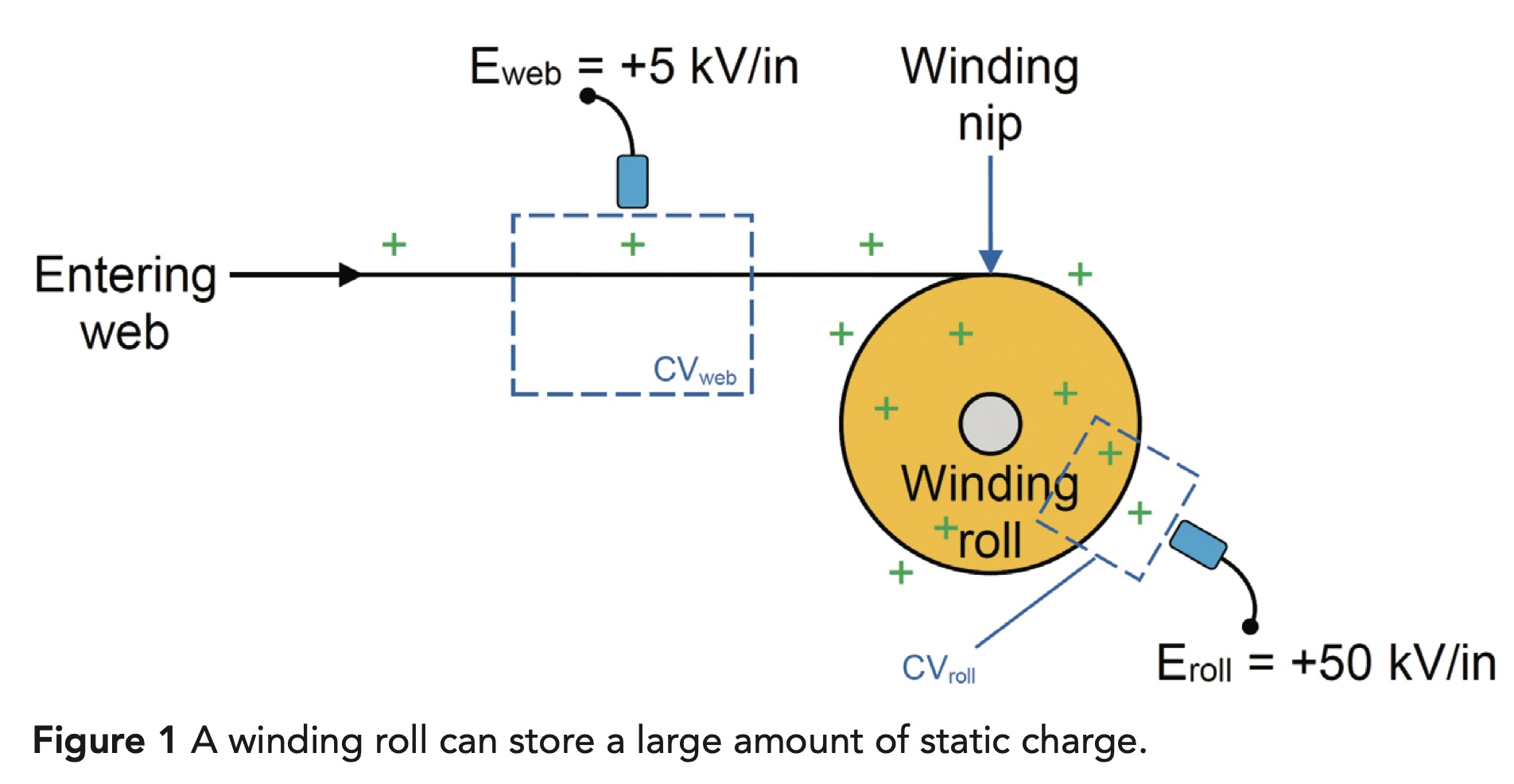

Even a little bit of static charge on the entering web in Figure 1 can cause in high static on the winding roll. Reading Eweb on the entering web responds to all the charges inside control volume CVweb. The reading of +5 kV/in shows that there is just a small amount of positive static on the entering web. Reading Eroll responds to all the charges in control volume CVroll, which extends into the winding roll. The reading of +50 kV/in, which is very high, shows that there are many charges inside the control volume.

A winding roll can store a long length web. For example, when winding a 2 mil (50 um) thick web on a 4-inch diameter core, a 20-inch (~0.5 meter) diameter winding roll stores web length of about 12,000 feet (3,700 meters). The winding roll also stores all the charge on this length of web. Even a small amount of static charge per foot on the entering web can cause a large amount of static on the winding roll.

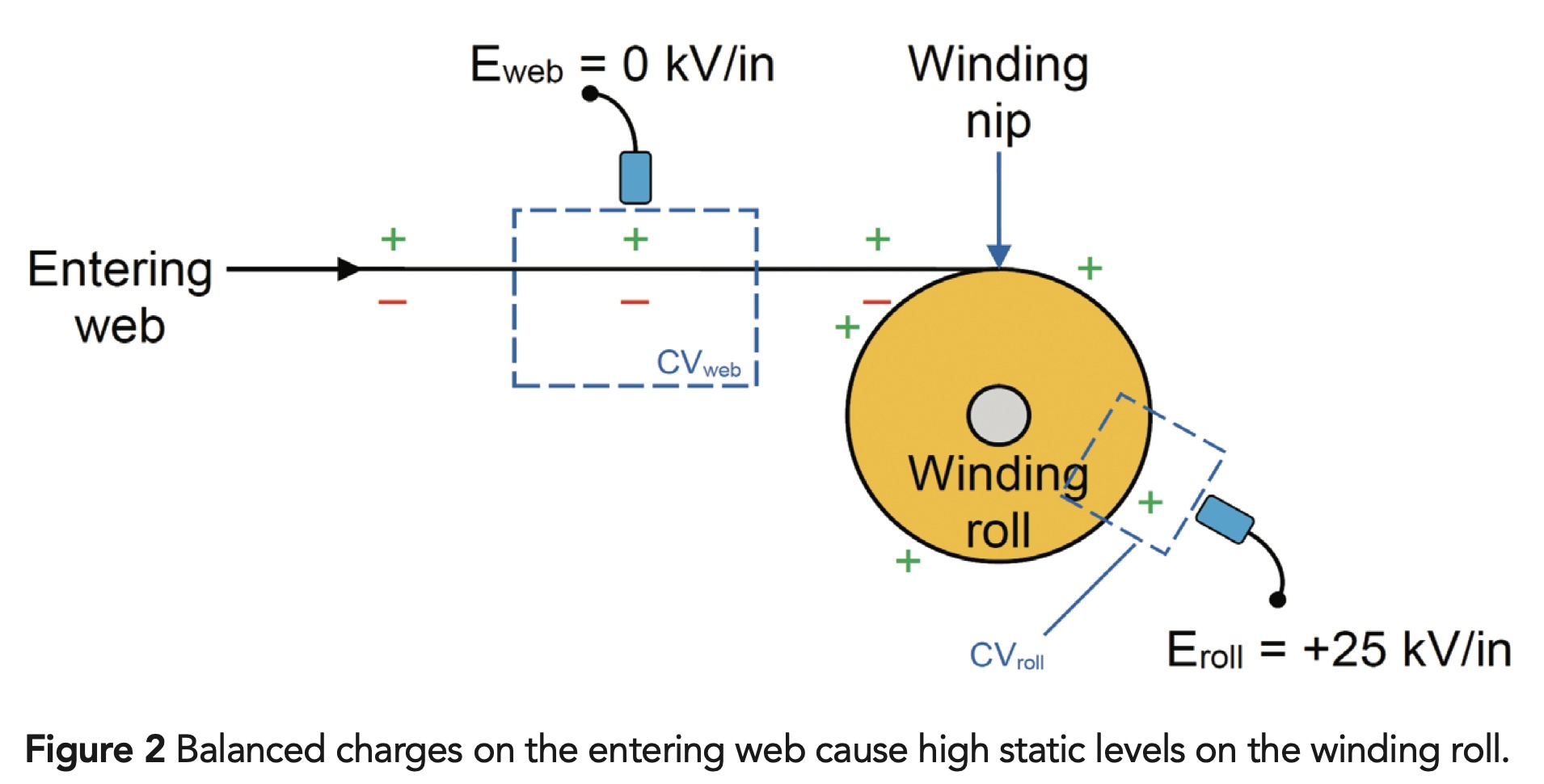

Even though the entering web in Figure 2 is charge neutral, it can cause in high static levels on the winding roll. The entering web has balanced charges where one surface has positive charges, and the other surface has an equal number of negative charges. Reading Eweb responds to all the charges inside control volume CVweb. While there may be a lot of static charges inside CVweb, there are equal numbers of positive and negative charges. So, the fieldmeter displays 0 kV/in meaning that the web is charge neutral.

As the web winds onto the winding roll, the positive charges on the top surface of the web wind onto the outside of the roll. As the winding roll turns, these positive charges enter the winding nip. If the charge density is uniform down the length of the web, for every positive charge on the outside surface of the winding roll that enters the winding nip, there is a negative charge on the bottom surface of the entering web. So, the volume of the winding roll is approximately neutral. Reading Eroll, which responds to all the charges inside control volume CVroll reads +25 kV/in indicating that there

are many positive charges on the outside surface of the winding roll.

Balanced charges are very persistent. Powered static bars and passive dissipaters cannot neutralize balanced charges because these devices respond just like fieldmeters. Since there are an equal number of positive and negative charges on the web, a static dissipater sees the web as “neutral” and contributes no neutralizing ions. Similarly, balanced charges persist through coating operations. Depositing a layer of conducting liquid on one surface of the web does not change the charges on the other surface. So, the balanced charges persist through coating.

To determine if balanced charges are causing high static levels on the winding roll, take readings Eweb and Eroll shown in Figure 1 and Figure 2. Note the polarity of the readings. If the polarities are different, then the entering web has balanced charges.

If Eroll is large (greater than ±15 kV/in) and Eweb is nearly zero (less than ±2 kV/in), then the entering web very likely has balanced charges.

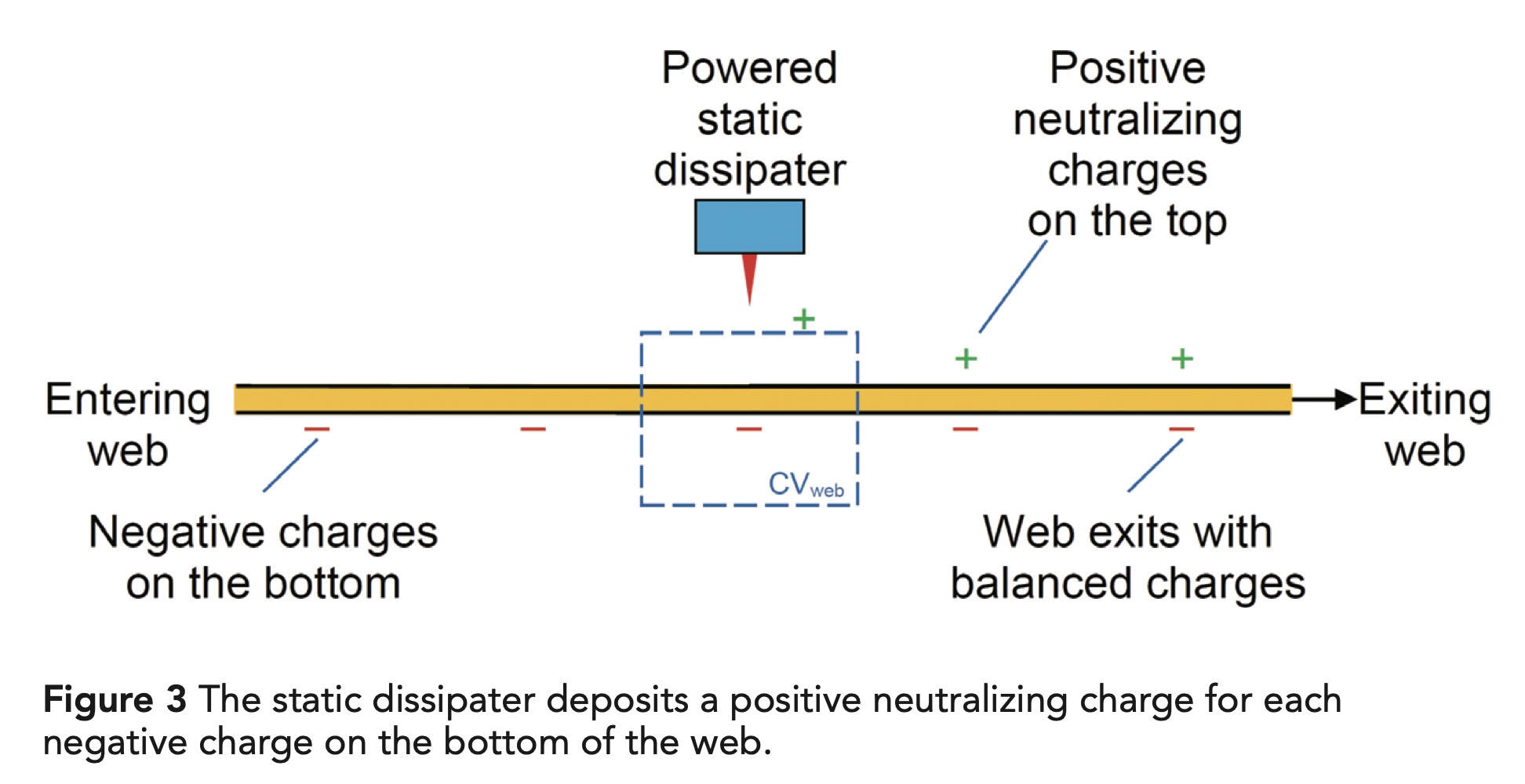

Solve this problem by practicing good static control upstream of the winding roll. Balanced charges are usually caused by installing a static dissipater on the wrong side of the web. In Figure 3, the entering web has negative static charges on the bottom surface perhaps from touching a rubber nip roller or other source of static charging. The powered static dissipater, facing the uncharged, top surface, responds to all the static charges inside control volume CVweb. The static dissipater deposits one positive, neutralizing charge on the top surface for each negative charge on the bottom surface.

The exiting web has one positive neutralizing charge on the top surface for each negative charge on the bottom surface. The charges on the bottom surface of the web are not changed by the static dissipater because the dissipater faces the other surface.

Fix this problem simply by moving the powered static dissipater so that it faces the bottom, charged surface.

Winding rolls can store large amounts of charge even when the entering web is “neutral.” To see if balanced charges are causing high static on a winding roll, measure the static level on the web entering the winding roll and on the winding roll. Solve this problem by practicing good static control upstream of the winding roll.

About the Author

Dr. Kelly Robinson writes on static issues occurring in converting processes. Robinson founded Electrostatic Answers, has 40-plus years experience in industrial problem solving and was named Top Manufacturing Consulting Services Provider 2023 by Managing MFG. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..