Toray Carbon Fiber Recycled from Boeing 787 Wing Production Process Applied in Lenovo ThinkPad X1 Carbon Gen 12

- Published: December 15, 2023

Toray Industries, Inc. Has announced the successful development of recycled carbon fiber (rCF) derived from the production process of the Boeing 787 components using Toray’s advanced carbon fiber, TORAYCA™. The rCF, which is based on pyrolysis recycling process, has been integrated into the Lenovo ThinkPad X1 Carbon Gen 12 as reinforcement filler for thermoplastic pellets. Toray and Lenovo will continue to collaborate to expand the usage of rCF in other Lenovo products.

Toray rCF is the outcome of Boeing and Lenovo’s shared commitment to minimize their environmental impact. Boeing’s objective is to reduce solid waste going to landfill and produce recyclable materials, while Lenovo has been exploring materials to reduce the carbon footprint of their products. Toray rCF connects these visions by repurposing Toray’s high-performance carbon fiber from the Boeing aircraft production process into Lenovo’s ultra-light laptop PC.

Mr. Yasumichi Tsukamoto, executive director and distinguished engineer, Commercial Product Solutions Development, stated, “Lenovo is committed to implementing sustainable practices and strive to make a positive social and environmental impact through our business. Working with Toray and Boeing to integrate recycled carbon fiber material into our next generation ThinkPad X1 Carbon is another step in our transition to a circular economy.”

Collaborating with universities and industry, Boeing has helped advance technology for recovering carbon fiber from composite materials – diverting it from landfill and creating a market for this high-value recycled material as feedstock for new products, including laptop casings. Using carbon fiber composite materials on Boeing airplanes reduces weight thereby increasing fuel efficiency. As reuse of residual carbon fiber composite materials from airplane manufacturing processes increases, product lifecycle impacts are further reduced.

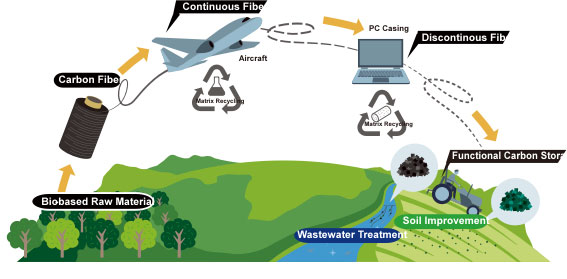

TORAYCA™ is an established aerospace material known for its high strength, stiffness, and lightweighting properties. These qualities have led to its adoption in other applications such as electrical and electronic equipment housings, sports equipment, and other industrial applications. As a carbon fiber leader, Toray aims to pursue and highlight efforts to achieve carbon neutrality by helping its customers enhance its product life cycle assessment (LCA)1, reducing the life cycle inventories (LCI)2 of carbon fibers, prepregs, and other products, and building a carbon fiber “materials ecosystem” (recycling and using bio-based raw materials)3.

A key advantage of carbon fiber is the ability to retain its primary mechanical properties even after the recycling process. Toray is actively advancing recycling technologies and establishing a strategic business model for rCF. Given that the carbon footprint of rCF is lower than that of virgin carbon fiber, Toray is proactively recommending the adoption of rCF to reduce the environmental impact of customers’ products. This commitment aligns with Toray’s dedication to fostering a circular economy, thereby reducing landfill waste.

One of the perspectives of the Toray Group’s Sustainability Vision for 2050 is a world in which people manage resources sustainably. The company will continue to pursue research and development to help materialize a sustainable, circular economy and realize its corporate philosophy of contributing to society by creating new value with innovative ideas, technologies, and products.

1 A life cycle assessment (LCA) is a methodology for quantitatively evaluating resource inputs, environmental impacts, and their effects on the planet and its ecosystems across the life cycles of products or other goods.

2 A life cycle inventory (LCI) is an analysis method for collecting, verifying, and compile input and output data on raw materials usages, resources consumption, environmentally hazardous substance emissions, and wastes at each lifecycle stage.

3 Carbon fiber is the only bio-based structural material. It is extremely stable, retaining its key mechanical properties even after recycling. Toray aims to build an ecosystem that leverages the unique characteristics of carbon fiber.