Addressing Plastic Waste with Mono-web Coatings

- Published: October 26, 2023

By Rick Stokes, Vice President — Coatings Group in North America, Sun Chemical

As brands continue to focus on ways they can improve the sustainability of packaging, they feel an urgency to address plastic waste, especially plastics in the ocean. According to a survey1 conducted by McKinsey & Company in April 2023, of all the various environmental concerns consumers have about packaging, plastic waste is the largest.

A recent report2 from The Organization for Economic Co-operation and Development revealed that the amount of plastic waste generated each year has doubled during the last two decades, with about 40 percent of that coming from packaging. It’s projected to more than double again by 2040 if significant changes aren’t made.

This has led major brand owners to join various regional plastics pacts around the world to address this issue, including the US Plastics Pact, and make public commitments to increase the rate of recycling and recycled material use in their packaging by 2025 and beyond.

Single-use plastics are also a focus of legislation around the world to address the plastic waste problem. Canada, for example, published the Single-Use Plastics Prohibition Regulations3, designating six single-use plastic product types as toxic and banning them under the Canadian Environmental Protection Act (CEPA) in a staggered timeline from 2022 to 2025.

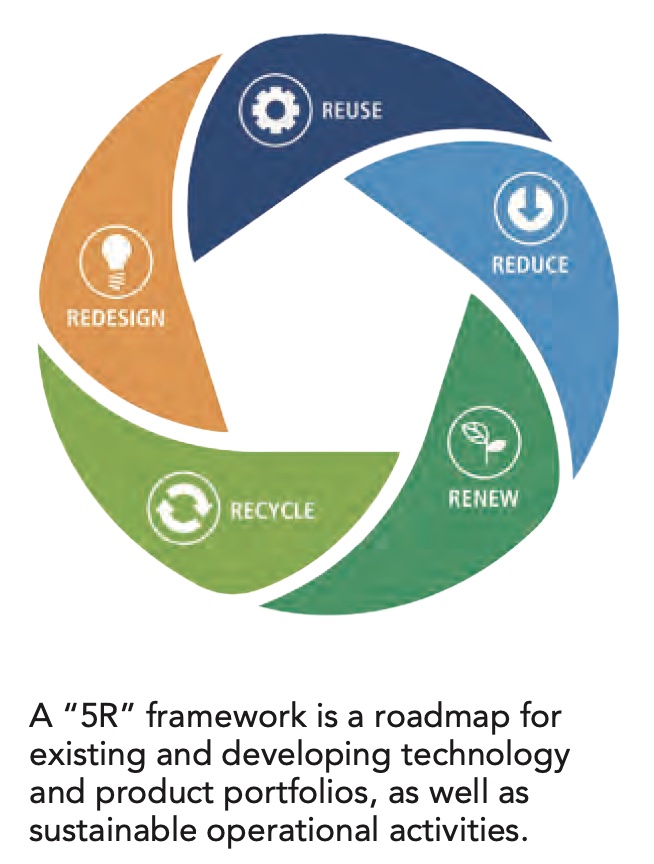

All of these trends mean that packaging producers must redesign to avoid single-use plastics designations while also enhancing recyclability, reuse or biorenewability.

The transition from lamination to mono-web structures can save on the use of adhesive, film, processing time and final label weight — all of which reduce the environmental footprint and use of virgin resources. Mono-web structures can also decrease the weight of a package, ultimately reducing transportation emissions.

That being said, lamination has been and continues to be a very popular way to protect consumer goods in packaging. It protects and improves the longevity of the packaging substrate from general wear and tear. Inks and coatings adhere to it relatively easily and it is reliable.

The challenge now is that it isn’t always sustainable. Many lamination structures combine multiple layers of plastic films that together are hard to separate from the packaging, making it virtually impossible to recycle, compost or use again in any meaningful way.

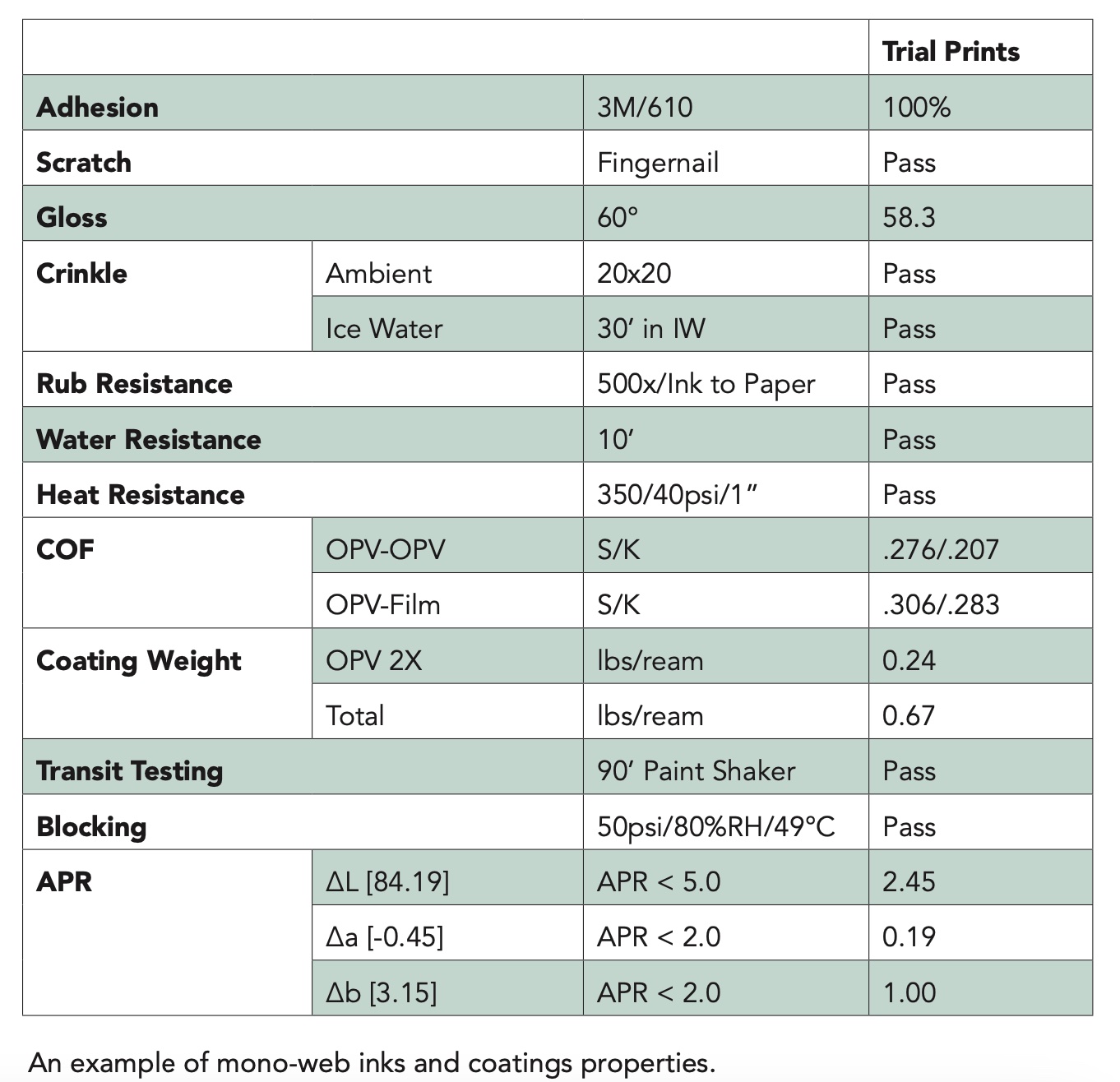

Mono-web inks and coatings have been developed to replace multi-play laminate structures using surface printing inks and an overprint varnish. Concern about mono-web packaging structures is that it could give up the protections that lamination offers.

The new mono-web coatings, however, can be very effective at providing many of these same properties. Although not readily visible and seldom recognized by consumers, these coatings bring unique attributes which allow today’s packaging to perform as well as it does.

Not only can these coatings provide the scuff and scratch resistance needed to replace a protective layer of film, they can continue to provide the benefits that coatings provide in laminated structures. Shelf appeal can be improved through matte and tactile effects which can attract customers and promote sales. Slip packages within the coatings provide proper frictional properties to allow for high-speed filling, which reduces waste and production time. Oxygen barrier coatings can be incorporated to improve the shelf- life of the packaged foods. The protective coatings can also pull double duty as a release coating so that cold-seal adhesives can be used to facilitate high-speed package filling.

To achieve both the sustainability and performance attributes required for packaging involves inks, coatings and adhesives working together seamlessly. Being able to provide the full scope of solutions from one source can lead to synergistic benefits where the layers work together for a sum greater than the parts. A mono-web packaging structure, for example, must use inks and coatings designed specifically for that mono-web material.

Mono-web coatings can reduce the amount of plastic used and make plastic waste more recyclable. Investment will be needed in recycling facilities to capitalize on the generation of more recyclable plastic packaging.

About the Author

Rick Stokes advances and diversifies Sun Chemical’s portfolio of coatings, adhesives and sealants by leading an experienced and accomplished team of product management, business development and application professionals. Building on its leadership position in inks, Sun Chemical has grown into one of the world’s leading suppliers of coatings and adhesives to the printing and packaging industries. Rick can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..