Addressing Bio-film/Compostables and Plastic Film Processing Challenges

- Published: March 18, 2024

By Tom Kerchiss, Chairman, RK PrintCoat Instruments Ltd.

There are a number of bio-based and other materials becoming available that go some way towards meeting environmental concerns. The one that perhaps everyone will be familiar with is cellulose, the main cell wall constituent of plants.

Typically associated with paper and board, the fibers when separated and processed using small amounts of natural and synthetic binders lead to the production of cellulose film or cellophane. Cellulose can also be made into cellulose acetate. This is manufactured by cellulose reacting with acetic anhydride.

The formulae is precipitated in water, dried and dissolved in acetone prior to being cast as a film. In its uncoated form it is highly permeable to moisture but is highly resistant to bacteria, aroma and flavor. Most cellulose-based films are coated, metallised or laminated. Coatings can be synthetic or bio based.

Biopolymers can be obtained directly from natural substances that include polysaccharides and proteins or by the polymerisation of monomers derived from

Biopolymers can be obtained directly from natural substances that include polysaccharides and proteins or by the polymerisation of monomers derived from

a biomass. An example that most packaging technologists will be aware of is polylactic acid or PLA.

Bio-based polymers can be an alternative to materials such as petroleum-based plastic rigid and flexible filmic materials. Bio-based materials are being developed, as we all know, to be biodegradable and/or are compostable when they reach the end of their life cycle. But it is far from a straightforward process; ink manufacturers, coating suppliers and other supply chain partners are involved in any development program. Also, in the loop are those connected with determining whether materials will run effectively on the various types of processing machines without compromising on product viability and commercial objectives.

The production of plastic film and subsequent conversion will undoubtedly become more focused. Customer bespoke filmic production for specialist applications is likely to remain important and for the reasons now outlined.

The technical characteristics and performance properties of filmic-related materials have enabled converters to produce products that would have been impossible to create with paper-based materials. Structured filmic multi-web or combo materials have enabled converters to produce packaging with graphics that could withstand not only the temperature extremes associated with frozen foods and pasteurization, but also the wear and tear of product filling lines.

Consider for example oriented polypropylene. Films such as oriented polypropylene (OPP) films when surface treated are often suitable for conversion with water-based inks, adhesives and cold seal, as well as with heat-activated sealants and coatings.

OPP films that have the ability to be convertible on both sides can be printed primarily by flexo, gravure or conceivably by a hybrid arrangement, laminated or metallized to produce cost-effective packaging products that look good and with good barrier properties. However, and from an ink formulator’s perspective, polypropylene is perhaps the film with the greatest potential for variance owing to the presence of antioxidants, stabilizers and slip compounds.

OPP films that have the ability to be convertible on both sides can be printed primarily by flexo, gravure or conceivably by a hybrid arrangement, laminated or metallized to produce cost-effective packaging products that look good and with good barrier properties. However, and from an ink formulator’s perspective, polypropylene is perhaps the film with the greatest potential for variance owing to the presence of antioxidants, stabilizers and slip compounds.

Filmic structures including OPP present problems if an operator treats them in a cavalier fashion. Not all films are the same; all have their quirks. But this can also be said of other materials, including synthetic papers, co-joined structures such as pouches and probably the same will be said of bio-based and compostable materials when they become more widely available and acceptable.

Oriented polypropylene (OPP) is a well-known and versatile material. It is strong, dimensionally stable and is suitable for applications that require a degree of permeability. Alternatively OPP can be engineered to provide the desired barrier resistance not only for many flexible packaging purposes but also for many industrial applications.

Specialization — the product, print and conversion of ultra-thin films for non-woven applications, the construction sector, scientific and technical, electronics and countless other areas of perhaps, low volume but high value — may well be the future for many films.

About the Author

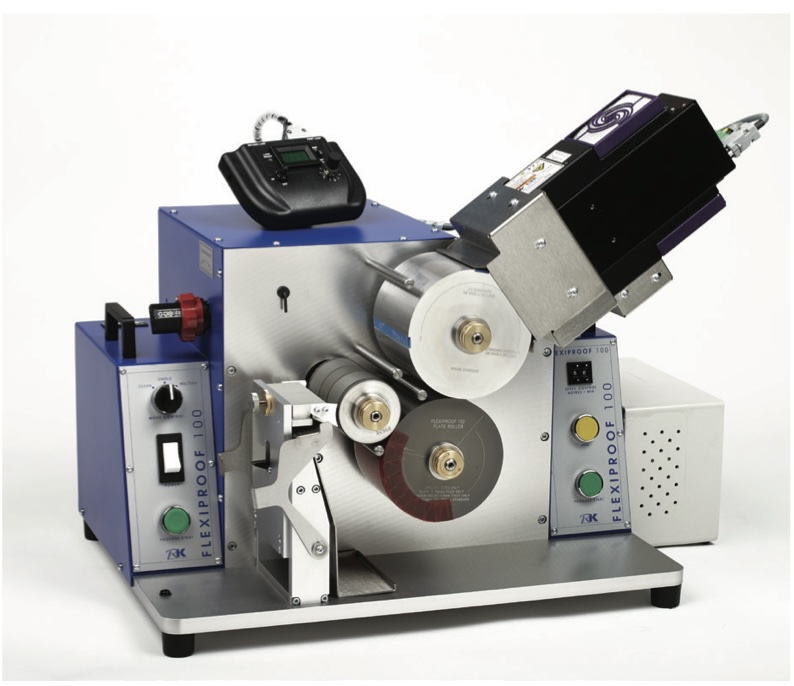

Tom Kerchiss is the chairman of sample preparation system and print/coat/laminating technology specialist for RK Print-Coat Instruments Ltd. The company, which won an Innovator in Pre-Press Award for the FlexiProof 100, supplies printing ink manufacturers, both large and small, as well as printers, converters and other businesses with color communication devices for all of the major print disciplines.