HYBRID Software Brings Leadership in Innovation to LabelExpo Europe

HYBRID Software brings a presence to Hall 8, Stand B/45, as Labelexpo Europe returns to Brussels September 11-14. This is a challenging time for the label industry, with a perfect storm of high prices for energy and substrates, a shortage of skilled labor, and higher interest rates that make capital equipment purchases more challenging. At Labelexpo, HYBRID Software will demonstrate its continued innovation to boost productivity and improve the competitiveness of its customers who print and convert labels.

HYBRID’s CLOUDFLOW software is used for workflow automation by thousands of label printers and converters worldwide. But industry consolidation has resulted in many printers with multiple printing locations, so centralizing prepress automation in the cloud provides a real advantage. MyCLOUDFLOW delivers all the power of CLOUDFLOW in a multi-tenant workflow solution hosted in the AWS cloud and managed by HYBRID Software to provide ease of use and extreme performance that is scalable on demand. MyCLOUDFLOW is not just for multi-site printers; even smaller label companies can benefit from lower infrastructure costs, with no servers to purchase or local IT support required, and a new customer can be up and running in a matter of hours.

True workflow automation requires a tight link between workflow and MIS/ERP systems so that the parameters for an order can be used to create the job layout and drive platemaking systems or digital presses. At Labelexpo, HYBRID Software will highlight MyCLOUDFLOW’s turnkey integrations with CERM, Label Traxx, and Radius, the leading MIS systems used in labels and packaging today. HYBRID Software will also demonstrate a major new release of Packzimizer for automated lane planning of label repetitions for digital print production as well as stacked label imposition for sheet-fed “cut & stack” label production.

With many label converters producing shrink sleeves and in-mold labels, 3D modeling has become an important prepress tool for the label industry. HYBRID Software acquired industry-leader iC3D last year and has now integrated their technology into Proofscope for high quality 3D rendering of labels and shrink sleeves, including photorealistic ray tracing and visualization of embellishments. This process can be automated with MyCLOUDFLOW for efficient production.

Workflow is only part of the story; creating high quality, press-ready labels remains a challenge for the industry, and HYBRID Software has continued to innovate with many new capabilities in the PACKZ editor. Content XML is a new technology in PACKZ and CLOUDFLOW which provides data-driven creation of labels and packaging by inserting text, graphics, and other design elements dynamically from an asset database. This is especially useful for creating multiple copies of a label in different sizes or languages and for managing nutrition facts and ingredients panels, but it can be extended for many other complex label applications.

PACKZ Advanced Color uses technology from HYBRID’s ColorLogic division to provide an accurate snapshot of printed artwork under various printing conditions, including different spot color strategies. The feature is designed to help label and packaging producers accurately reproduce brand colors using the fewest number of inks and the least amount of each ink to achieve the lowest production cost. Once the spot color strategy has been selected, it can be applied automatically using MyCLOUDFLOW for all future instances of that color.

HYBRID’s variable data printing (VDP) software has been enhanced for easier preparation of variable data labels for digital printing. Its output format is standard PDF which is compatible with any RIP, but it has been especially optimized for HYBRID’s own Harlequin RIP, the world’s fastest RIP used by many preeminent manufacturers of digital presses as well as HYBRID’s own Digital Front Ends: Xitron NavigatorDFE and Global Graphics SmartDFE. Customers tell us that PACKZ VDP jobs print up to four times faster than VDP jobs created with other software, enabling digital presses to run faster and produce more labels per shift.

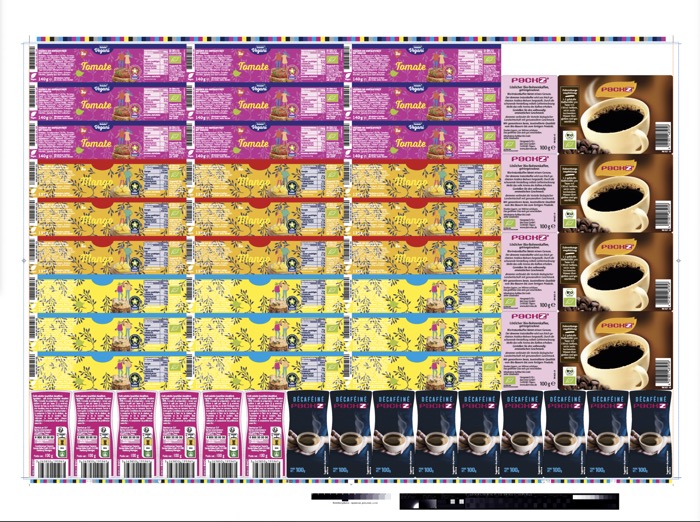

But digital printing isn’t the only game in town; most labels are still printed with flexo, offset, or gravure presses, and HYBRID Software continues to innovate in analog printing as well as digital printing. At Labelexpo, visitors can see a variety of print samples from HYBRID Software’s new Velvet Screening, the next generation hybrid AM/FM screening technology for flexo printing which provides unprecedented control of highlight dots and smoother gradations on all types of flexo plates, even at lower output resolutions. Velvet Screening can also be combined with Intelligent Flexo, the surface screening solution for high quality flexo printing across a wide variety of plates and substrates.

For more information, visit www.hybridsoftware.com.