Show Preview | ICE USA 2015 Returns to Orlando with Added Features

- Published: January 06, 2015, By Claudia Hine

PFFC’s “Static Beat” columnist Kelly Robinson is part of expanded “Ask The Experts” program and presents at CEMA pre-show seminar along with "Coating Matters" columnist Mark Miller.

Attendees at the 2015 ICE USA Exhibition, which takes place February 10-12 at the Orange County Convention Center in Orlando, FL, will benefit from an expanded “Ask The Experts” program that offers one-on-one complimentary appointments with some of the industry’s leading consultants. Dr. Kenneth McCarthy (clean room coating) and German Laverde (doing business in Latin America) will join Dr. Edward Cohen (web coating), Vincent DiTrolio (flexo printing), Dr. Dave Roisum (web handling), Dave Rumson (slitting/rewinding), and PFFC’s own Kelly Robinson (static control).

Attendees at the 2015 ICE USA Exhibition, which takes place February 10-12 at the Orange County Convention Center in Orlando, FL, will benefit from an expanded “Ask The Experts” program that offers one-on-one complimentary appointments with some of the industry’s leading consultants. Dr. Kenneth McCarthy (clean room coating) and German Laverde (doing business in Latin America) will join Dr. Edward Cohen (web coating), Vincent DiTrolio (flexo printing), Dr. Dave Roisum (web handling), Dave Rumson (slitting/rewinding), and PFFC’s own Kelly Robinson (static control).

Bob Chiricosta, director, North American exhibitions, calls "Ask The Experts" one of the most popular and valuable features of the show. Attendees can schedule 15-min appointments with any of the experts during all three days of the show.

Mack Brooks Exhibitions, organizer of ICE USA, expects several thousand converting professionals from nearly 50 countries to attend this year’s event.

Keynote Addresses

Free for all ICE USA attendees, a daily keynote session will be presented from 9:00–10:00 a.m. At press time, the Tuesday keynote session had not yet been announced.

Wednesday, February 11

"Ask the Expert" participant German Laverde, director of Plasto Intl. LLC, will present the keynote address on Wednesday. Laverde will discuss the realities and challenges of expanding your business in Latin America.

"Ask the Expert" participant German Laverde, director of Plasto Intl. LLC, will present the keynote address on Wednesday. Laverde will discuss the realities and challenges of expanding your business in Latin America.

“Although my presentation will focus on the Latin American marketplace, I will also address specific strategies and offer valuable insights that can be beneficial to converters doing business in North America and around the world,” Laverde said. “I will provide information and examples of how cultural challenges, market trends, common misconceptions, and language barriers can affect business opportunities.”

Laverde has 30+ years of experience connected with business in Latin America, including positions in Exiplast and Plastilene in Colombia, as well as 14 years with Battenfeld Gloucester Engineering in the US. He has also worked for PTI as VP/director of sales–Latin America and for Cloeren Inc. as director of sales–Latin America.

Thursday, February 12

Thomas E. Blaige, chairman and CEO of Blaige & Co., will present “Lead, Follow or Get Out of the Way: Global Consolidation in Flexible Packaging,” on Thursday. His keynote will focus on the impact of global consolidation on the flexible packaging market, based on Blaige & Company’s comprehensive Twelve Year Plastics and Packaging Merger & Acquisition Consolidation Study. With consolidation activity showing strong momentum in the coming years, Blaige will provide summary analysis from the 70-page study, and cover valuable strategies to help company owners understand how to survive and thrive in an increasingly competitive market.

Thomas E. Blaige, chairman and CEO of Blaige & Co., will present “Lead, Follow or Get Out of the Way: Global Consolidation in Flexible Packaging,” on Thursday. His keynote will focus on the impact of global consolidation on the flexible packaging market, based on Blaige & Company’s comprehensive Twelve Year Plastics and Packaging Merger & Acquisition Consolidation Study. With consolidation activity showing strong momentum in the coming years, Blaige will provide summary analysis from the 70-page study, and cover valuable strategies to help company owners understand how to survive and thrive in an increasingly competitive market.

“There are three things owners look at in terms of selling: their company’s performance, the external market, and are they psychologically ready,” said Blaige. “My presentation will address these areas.”

Blaige established his international banking firm dedicated to the plastics, packaging, and chemical industries. He has 30 years of transaction experience, completing more than 200 transactions. He has visited more than 400 plastics, packaging, and chemical operations in 40+ countries.

The Fun Stuff

Shingle Creek Golf Club is again the site of the golf tournament, which will be held February 9. The Four Man Scramble format will allow golfers of all skill levels to participate.

ICE USA welcomes all attendees and exhibitor staff to its inaugural Networking Event on Tuesday, February 10, from 5:00-7:00 p.m. on the show floor. Enjoy a complimentary beverage, live music by the Landsharks, and snacks while mingling with your industry colleagues.

Job hunting? To help companies find qualified candidates for job openings, ICE USA will place a “Recruitment Wall” on the show floor where attendees can see current job postings by exhibiting companies.

Booth Descriptions

More than 300 exhibitors will showcase the last innovations and converting technology at this year’s show. Be sure to visit the PFFC staff at Booth 1050 to learn how we can help grow your business, to get listed in our industry-leading directories, and to sign up for a free subscription to E-Clips. Here is a sneak peek at what you’ll see on the show floor.

AccuWeb Inc. (Booth 211) will show the new EVO 150 web guide control, which can be ordered for DIN rail mounting or in one of three IP65 rated enclosures with optional switchpad or touchscreen HMI. The 24V DC operation integrates easily into existing lines or control panels. With 150 watts of power, the EVO 150 can drive all brushed or brushless actuators. The new TA Actuator is the company's smallest actuator, yet 200% faster than other actuators and with enough power to move any steering guide. Its brushless motor design means no actuator maintenance. Called ideal for web applications up to 36 in. wide. Being unveiled for the first time, DualEdge Technology will show attendees how the EVO 150 controller can provide perfect centerline guiding with the use of a single WideArray edge detector. Web widths up to 18 in. are possible.

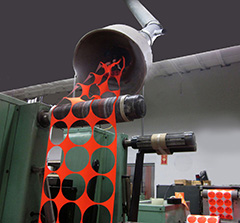

AirTrim (Booth 1166) will feature trim waste and dust removal systems for printing and converting lines. Continuous stream or chopped systems can be developed to suit any application. In addition to complete systems that can be sized for future expansion, AirTrim offers a variety of portable systems that allow a waste trim removal unit to be located when and where it is needed. Rental systems are available to verify ROI and gain capital approval. Each system is designed to provide transmission and containment optimized for that particular application, complete installation and/or start up assistance is optional.

AirTrim (Booth 1166) will feature trim waste and dust removal systems for printing and converting lines. Continuous stream or chopped systems can be developed to suit any application. In addition to complete systems that can be sized for future expansion, AirTrim offers a variety of portable systems that allow a waste trim removal unit to be located when and where it is needed. Rental systems are available to verify ROI and gain capital approval. Each system is designed to provide transmission and containment optimized for that particular application, complete installation and/or start up assistance is optional.

Alpha Converting (Booth 1214), a manufacturer of slitting, web handling, and converting machinery, is spearheading a new campaign to find more regional distributors and back its current sales in the US. The ALPHAMATIC TURRET is designed for single person operation and provides a highly efficient and flexible solution for short- and medium-run work. It runs to the length set by the operator, turrets, loads fresh cores, strips the roll from the rewind shaft, and is delivered to a roll closing system with ID labeling and bar coding. As standard, the winder is supplied with an adhesiveless start (cinching system).

American Cutting Edge, a Div. of CB Mfg. (Booth 110) will display industrial circular blades and knives. Company acquired new machinery for the manufacture of tungsten carbide blades. The machinery will focus on the manufacture of parts for the slitting and fiber markets. Will continue to stock a large inventory of tungsten carbide blades.

Anilox Roll Cleaning Systems (Booth 1172) offers Laser Cleaning Systems for cleaning all types of printing and coating rolls. Process is chemical and dust free. No cleaning media is required, so no consumables to purchase and no waste is generated. Uses only a small amount of electricity (no air or water required). Can clean ultra high line screen rolls. Company provides both on-site and off-site cleaning services.

ASHE America Inc. (Booth 201) will showcase its Sapphire S2 duplex slitter rewinder and present primary and secondary slitter rewinders for film producers as well as dedicated machines for paper and label stocks. Representatives will explain the duplex center winder's features along with the company's range of slitting machinery in varying widths, between 13 in. for the self adhesive label producer to a maximum width of 342 in. for manufacturers of biaxially oriented films.

ASHE America Inc. (Booth 201) will showcase its Sapphire S2 duplex slitter rewinder and present primary and secondary slitter rewinders for film producers as well as dedicated machines for paper and label stocks. Representatives will explain the duplex center winder's features along with the company's range of slitting machinery in varying widths, between 13 in. for the self adhesive label producer to a maximum width of 342 in. for manufacturers of biaxially oriented films.

Atlas Converting North America (Booth 721) will focus on the new generation Titan SR9 Series secondary slitter/rewinders said to provide unsurpassed levels of slitting productivity and rewind reel quality in machine widths of 65 and 88 in. (1650 and 2250 mm) for high volume production printers and converters. New features include reduced power consumption, faster set-up time, and improved sustainability showing respect for the environment. A unique Linear Tracking Slitter section (LTS) ensures a short and constant web length between the knives and rewind shafts to deliver the highest quality rewind reels with a maximum speed of 3,00 fpm (1,000 mpm). William Cowan, sales manager for Atlas and Titan in North America, will present a technical paper as part of the AIMCAL-sponsored Keynote Conference Presentations on Web Slitting at 10.30 a.m. on Thursday, February 12. The presentation will cover the efficiency of automatic knife positioning systems against manual systems by using a computer program to calculate differences in productivity.

AZCO Corp. (Booth 615) will showcase its modular FGW-1000 sheeter. Simple to use, the roll of material is placed onto an air shaft, which is supported by safety chucks for quick roll changes. A motorized unwind with a dancer assembly provides constant web tension as the material goes over the ball-bearing idler rollers. Precision ground urethane rollers are turned by a brushless servo motor, allowing for clean cut lengths while keeping maintenance low.

Badger Plug Co. (Booth 1251) will present a wide assortment of roll protection products, including a selection of core plug models and sizes in metal, plastic, and wood and from lightweight to heavy duty. Slit roll protection products include a selection of Double lugs and Single Plugs used to securely stack and unitize rolls. Plastic Pad Plugs are available in dozens of configurations and sizes to safely suspend light and medium weight roll products. Heavier rolls can be suspended using company's H-Pack System, which includes endboards, sleeve plugs, clips, and channels.

BERHALTER (Booth 735) is introducing PRElaser laser die-cutting technology. Multipack yogurt lids can be pre-perforated using this technology so the yogurt pots can be individually snapped off and separated without the lid being unintentionally removed. Inspection systems make it possible to inspect the print and material quality directly in-line on a BERHALTER die-cutting machine. Defective material thereby is passed through the tool area without being punched—delivering 100% controlled products.

BOBST (Booth 1121) will focus on two key innovations in vacuum metallizing. The AIOx process produces clear film with a good water and oxygen barrier level and can be used for baked goods and microwaveable food where product visibility is required. The Hawkeye Pinhole Detector is a monitoring system that detects defects at full metallizer speed, resulting in increases in production speed and final product quality. For coating, the product lines ROTOSIL, ROTOMELT, ROTOTACKY, and ROTOCOAT will be presented. These modular lines provide flexibility in the choice of the most suitable coating technology for coated and/or laminated products.

Cadence Inc. (Booth 1126) offers Endurium and Optima high performance razor slitter blades. Also introducing Diamaze Plasma sharpened blades manufactured by GFD in Germany. Made from industrial diamonds designed to last 1,000 times longer than conventional blades.

Carestream Tollcoating (Booth 242) provides enhanced contract manufacturing services that reportedly reduce customer development costs and improve product quality. Expert staff will divulge updates on the firm's expanding technologies that build on 100 years of coating leadership in photographic imaging and various advanced material applications, including security materials, packaging, and more. Structures can have up to 20 precision-coated layers in clean room environments involving several precision coating technologies, in-line corona discharge treatment, UV curing, lamination, on-line inspection, and multilayer coating from the same coating fixture or tandem coating. Also offered are formulation development, analytical/quality testing, mixing, slitting/sheeting, and supply chain management.

Catbridge Machinery (Booth 514) will show the next-generation Model 900 duplex center winder that rewinds to a 32-in. diameter, runs at speeds to 2500 fpm or more, slits to a minimum 1-in. width, and handles a broad range of materials. Advanced technologies and features precisely control roll edge quality and density. Available unloading systems include conveyors that bring finished rolls to remote packing stations. The Model 900 can integrate a variety of inline functions such as inspection or lamination, expanding to capabilities beyond just slitting and rewinding.

CoreTech Intl. (Booth 711) features an ergonomically designed core cutter with unique features, company says. S Series machines have enclosed, interlocked guard at a comfortable operator height and cut accuracy to ± 0.005 in. width tolerance; "E" & "L" upgrades respectively offer automatic mandrel height adjustments and an automatic loading system.

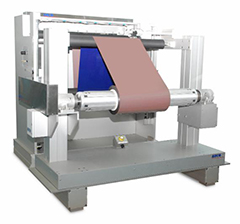

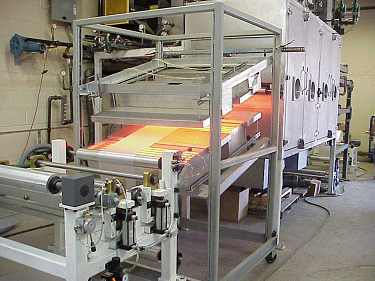

Davis-Standard LLC (Booth 411) will highlight new coating technology including a curtain slide coater and five-roll silicone coater. The curtain slide coater (pictured) applies single layer coatings at rates up to 2,800 fpm (853 mpm) with expansion capabilities up to two additional layers. The five-roll silicone coater is capable of applying 100% silicone at rates up to 2,400 fpm (732 mpm). This coater is constructed of stainless steel for ease of cleanup and includes a mist removal system. In extrusion coating, Davis-Standard recently introduced the dsX flex-pack to support cost-sensitive flexible packaging applications. This system is pre-configured to merge customer demand with the best components in the industry for better end-product quality, greater uptime and productivity, reduced production costs, and application versatility. It is also engineered with proven components and an adaptable machine configuration, making it ideal for converters, printing companies, multinational companies, and start-ups.

DiTrolio Flexographic Institute Inc. (Booth 154) offers industry-specific training seminars for all skill levels, from beginning press operations to advanced printing applications. Facility offers a state-of-the-art environment where new press operators and seasoned industry professionals, alike, can gain hands-on exposure to printing and finishing processes. Will have experts and top executives at the booth to answer all your questions.

Dover Flexo Electronics (Booth 102) will offer interactive demonstrations of its tension measurement, display, and control solutions. See the FireGuard2 Intrinsically Safe Tension Amplifier, which measures process tension while providing peace of mind to operators whose machines may be exposed to flammable solvent vapor. The EasyWeb Torque Controller keeps tension stable and within a desired tension range by tapering the torque down or up on a center-driven unwind or rewind based on an input signal from line-speed and roll-speed tachs, or from an ultrasonic sensor or rider roll. The SteadyWeb5 Tension Controller maintains set tension on a web in any zone. With Quik-Cal, it is configured in the demo to take a tension input signal from a narrow web tension transducer mounted on an adjacent display stand. A web-server option allows Ethernet communication for setup and control via connected PC or remotely from a wi-fi-enabled smart device.

EC Designs (USA) Ltd. (Booth 1101) manufactures the Elite Cameron range of core cutters, slitting and rewinding machines, and coating and laminating machines. Company will show the new CW800 slitter, a cost-effective solution for converters that require high running speeds and high quality finished rolls. Combines an overhead web feed, auto knife setting, knife cleaning, and a double sided contact web cleaning unit after slitting. Finished product is clean and free of any dust or contamination for medical, food, and digital printing customers.

Enercon Industries (Booth 1111) will show Compak ProFlex, its newest power supply innovation that provides a set of advanced features from an intuitive touch screen control interface. Unit is said to improve corona treating control. Highlights include universal input voltage compatibility; integrated start up features such as exhaust blower, electrode assemblies, and wet start for humid environments; local/remote/network control options; recipes, operator lockout, custom functions, and more.

Energy Sciences Inc. (Booth 1265) addresses your questions regarding electron beam (EB) cutting-edge green technology, including overall reduced costs, improved product quality, reduction of VOCs, adhesive choices without isocyanides, and who to contact for specific coating, ink, or substrate requirements.

Energy Sciences Inc. (Booth 1265) addresses your questions regarding electron beam (EB) cutting-edge green technology, including overall reduced costs, improved product quality, reduction of VOCs, adhesive choices without isocyanides, and who to contact for specific coating, ink, or substrate requirements.

Filmquest Group, Inc. (Booth 247) offers new proprietary Questar products to meet converters needs, including CP NanoShield clear PVdC-free barrier film with improved adhesion and new optional barrier levels; CP267 ultra low gloss/high COF matte film for a unique look and feel with reportedly the lowest gloss level of any film having a velvet touch; and CP270 high molecular bond metallized film that claims superior bond performance for solventless lamination. Representatives will explain company's demand-based supply chain management available through its PODS Program.

Filmquest Group, Inc. (Booth 247) offers new proprietary Questar products to meet converters needs, including CP NanoShield clear PVdC-free barrier film with improved adhesion and new optional barrier levels; CP267 ultra low gloss/high COF matte film for a unique look and feel with reportedly the lowest gloss level of any film having a velvet touch; and CP270 high molecular bond metallized film that claims superior bond performance for solventless lamination. Representatives will explain company's demand-based supply chain management available through its PODS Program.

GL&V USA (Booth 1134) will present information on its Cameron, Beloit, and Lenox line of slitter/rewinders. Will present new Magtrim automatic slitter positioning system, which is capable of setting all required knives in 5 seconds with an accuracy of ±0.004 in. Eight units have been installed with four more units on order. Slitter automation and safety upgrades will be featured. Company also offers equipment rebuilds, technical service, and engineering support.

Harper Corp. of America (Booth 848) will exhibit its patented, award-winning QD ink proofing system, the HIVE (High Image Volume Engraving) anilox rolls for high resolution printing, and high quality carbon fiber bridge and plate sleeves from Harper's newest HEX division. Company representatives will be on hand to showcase these products and services and provide additional information and insight regarding this technology.

Heraeus Noblelight America LLC (Booth 867) demonstrates its Light Hammer 10 Mark II with the latest versionn of the Advanced Integrated Monitoring System (AIMS). Staff will acquaint visitors with a diversity of product platforms, including Microwave UV curing systems, AMBA arc lamps, UV-LEDs, and low-pressure arc lamps. Company also offers UV process education, user training, lab facilities, demonstration equipment, and application assistance.

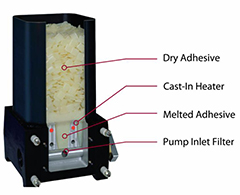

ITW Dynatec (Booth 325) will demonstrate the "char-proof" characteristics of its adhesive supply units said to eliminate the number one cause of performance issues when working with hot melt adhesives. Will be highlighting the numerous features of its extensive line of adhesive supply units and maintenance tips to prevent charring in your operation. Offerings range from small table top units to large, 2,000 lb capacity units that can pump thousands of pounds an hour.

ITW Dynatec (Booth 325) will demonstrate the "char-proof" characteristics of its adhesive supply units said to eliminate the number one cause of performance issues when working with hot melt adhesives. Will be highlighting the numerous features of its extensive line of adhesive supply units and maintenance tips to prevent charring in your operation. Offerings range from small table top units to large, 2,000 lb capacity units that can pump thousands of pounds an hour.

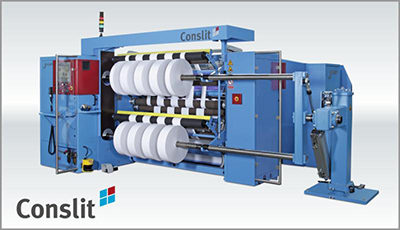

KAMPF Machinery (Booth 205) will present slitting and rewinding machinery that serves BOPP and BOPET film manufacturing, flexible packaging, paper, films and laminates, imaging, and aluminum foils. Conslit machine offers an extensive catalog of options. Also provides customized winding and spooling machines for these markets.

Lever Mfg. Corp. (Booth 621) will display the new Lever LS-7000 heavy duty, automatic single knife roll slitter, designed for converters that want to automatically slit a variety of materials and laminates on rolls with an outside diameter of up to 584 mm (23 in.) It features PLC operation with a color touch screen operator interface. Knife carriage movement is powered by a servo-driven linear actuator with a second linear actuator controlling automatic knife angling. A servomotor powered precision lead screw provides precise cutting tolerances.

Mahlo America Inc. (Booth 939) will exhibit on-line measurement solutions for light weight silicone coatings down to 0.25 micron and non-nuclear solutions for coating add on, thickness, moisture, calculated density, and air permeability. Will display patented DFI flutter independent beta gauge that is insensitive to web path position change in the measurement gap created from web tension variation, sag, or edge curl.

Montalvo (Booth 511) will debut three product lines along with their lineup of load cells, brakes, controllers, and sensors. The Z4 Tension Controller, Guardian Safety Chucks, and Open Loop Torque Sensing Control System (TSC) offer a variety of new functions, features, and patent-pending technology to improve the capabilities of existing and new machines. The Z4 (pictured) features a 7-in. HD display screen and is available in 110–240VAC and 24VDC versions. The Guardian chucks have a redesigned handwheel and journal seat and replaceable handwheel inserts that eliminate the need to replace worn handwheels. The TSC system is compact to save space and works with multiple control methods.

Montalvo (Booth 511) will debut three product lines along with their lineup of load cells, brakes, controllers, and sensors. The Z4 Tension Controller, Guardian Safety Chucks, and Open Loop Torque Sensing Control System (TSC) offer a variety of new functions, features, and patent-pending technology to improve the capabilities of existing and new machines. The Z4 (pictured) features a 7-in. HD display screen and is available in 110–240VAC and 24VDC versions. The Guardian chucks have a redesigned handwheel and journal seat and replaceable handwheel inserts that eliminate the need to replace worn handwheels. The TSC system is compact to save space and works with multiple control methods.

MTorres Disenos Industriales (Booth 351) will introduce the TorresWINDER surface rewinder. Designed for web widths to up 100 in. (2,540 mm), diameters up to 87 in. (2,130 mm) and winding speeds of up to 2,600 fpm (800 mpm) and capable of handling a wide range of substrates. Offers a contactless cutting system with latest safety and control technology. Options are available for shaft handling (extraction and loading) and can be included, depending on the customer's requirements. Can offer either Allen-Bradley or Siemens controls as standards.

NDC Technologies (Booth 901) will exhibit its latest offering of gauging systems. Sensor portfolio includes 12 technologies that can be configured to measure thickness, basis weight, moisture, and coat weight across a wide range of coating and converted products. Can be arranged as either fixed point or scanning measurements. Company also provides measurement and control solutions for continuous coating operations, plus specialty patch and stripe coaters. Infrared sensors include its IG710S backscatter sensor that can discriminate up to six components for high-resolution measurement of adhesives, wax, polymers, acrylic and water-based coatings. In addition, NDC’s SR710S infrared reflectance gauge is able to measure thin, clear coatings on metallic foils or metalized paper and plastics. Beta LaserMike LaserSpeed encoder measures the length and speed of any moving surface with better than ±0.05% accuracy without contacting the product. Uses laser-based technology to precisely measure both web and packaging products for paper, film, sheet, and foil. Applications include measuring product length and speed at the slitter/rewinder, regulating coating/laminating applications, controlling critical length cutting operations, adjusting roll speeds in flying-splice processes and monitoring web tension of products. Converters realize numerous production efficiencies and material savings.

NDC Technologies (Booth 901) will exhibit its latest offering of gauging systems. Sensor portfolio includes 12 technologies that can be configured to measure thickness, basis weight, moisture, and coat weight across a wide range of coating and converted products. Can be arranged as either fixed point or scanning measurements. Company also provides measurement and control solutions for continuous coating operations, plus specialty patch and stripe coaters. Infrared sensors include its IG710S backscatter sensor that can discriminate up to six components for high-resolution measurement of adhesives, wax, polymers, acrylic and water-based coatings. In addition, NDC’s SR710S infrared reflectance gauge is able to measure thin, clear coatings on metallic foils or metalized paper and plastics. Beta LaserMike LaserSpeed encoder measures the length and speed of any moving surface with better than ±0.05% accuracy without contacting the product. Uses laser-based technology to precisely measure both web and packaging products for paper, film, sheet, and foil. Applications include measuring product length and speed at the slitter/rewinder, regulating coating/laminating applications, controlling critical length cutting operations, adjusting roll speeds in flying-splice processes and monitoring web tension of products. Converters realize numerous production efficiencies and material savings.

New Era Converting Machinery Inc. (Booth 501) will accent its high speed, wide web turret unwind that allows automatic roll changeover at full production speeds. View a taped installation at Evergreen Packaging, Waynesville, NC, to see an identical system unwind 14,000-lb rolls of paper at speeds to 1,400 fpm. Also featured is a custom-built off-set slot die coater module for narrow web coating and a multi-roll kiss coater that simultaneously applies coating to both sides of a web. Said to reduce coat weights, eliminate scrap, and improve product performance. Last is a multi-bay drive panel incorporating Allen-Bradley drives and ControlLogix processor.

New Era Converting Machinery Inc. (Booth 501) will accent its high speed, wide web turret unwind that allows automatic roll changeover at full production speeds. View a taped installation at Evergreen Packaging, Waynesville, NC, to see an identical system unwind 14,000-lb rolls of paper at speeds to 1,400 fpm. Also featured is a custom-built off-set slot die coater module for narrow web coating and a multi-roll kiss coater that simultaneously applies coating to both sides of a web. Said to reduce coat weights, eliminate scrap, and improve product performance. Last is a multi-bay drive panel incorporating Allen-Bradley drives and ControlLogix processor.

New Way (Booth 456) launches Porous Media Technology that provides non-contact web handling for substrates. Enables flexible films to float over non-rotating air turns rather than contact rollers. The ability to drive the substrate in a directional and non-contact manner without the use of motors is also made possible using air bearings. Air Turns operate by attaching a pressurized air hose to the side of the unit, which allows air to pass through the Porous Media, thereby causing the moving substrate to float on a cushion or air. The Air Turn does not rotate, hence there are no moving components. Porous carbon surfaces feature millions of sub-micron-sized holes, which enable a thin, but robust air film across the bearing surface.

New Way (Booth 456) launches Porous Media Technology that provides non-contact web handling for substrates. Enables flexible films to float over non-rotating air turns rather than contact rollers. The ability to drive the substrate in a directional and non-contact manner without the use of motors is also made possible using air bearings. Air Turns operate by attaching a pressurized air hose to the side of the unit, which allows air to pass through the Porous Media, thereby causing the moving substrate to float on a cushion or air. The Air Turn does not rotate, hence there are no moving components. Porous carbon surfaces feature millions of sub-micron-sized holes, which enable a thin, but robust air film across the bearing surface.

Novation Inc. (Booth 753) will demonstrate the ScrapTracker system, which creates a data file or "roll map" associated with each roll of material manufactured, processed, or printed. The data file contains all information about the locations and types of defects within the roll. System uses the AF2 Web Flagger to apply flags with unique ID numbers. The flags are pre-printed with a unique number and a corresponding bar code. A flag can be triggered by an operator push-button or a signal from the machine. When a flag is signaled to be applied, the flag's ID number is recorded along with the type of defect and its location within the roll. Six different types of defects can be logged.

Novation Inc. (Booth 753) will demonstrate the ScrapTracker system, which creates a data file or "roll map" associated with each roll of material manufactured, processed, or printed. The data file contains all information about the locations and types of defects within the roll. System uses the AF2 Web Flagger to apply flags with unique ID numbers. The flags are pre-printed with a unique number and a corresponding bar code. A flag can be triggered by an operator push-button or a signal from the machine. When a flag is signaled to be applied, the flag's ID number is recorded along with the type of defect and its location within the roll. Six different types of defects can be logged.

PFFC | Paper, Film & Foil Converter (Booth 1050) will provide expert advice offered by our columnists on web handling, coating & laminating, printing, and static control. Editorial staff on hand to help you share your company news with our converter community. Expert columnists will be available to help with troubleshooting problems. Our sales staff can show you how we can help grow your business. Visit our booth to get listed in our industry-leading directories, join our Message Board forum, and sign up for a free subscription to E-Clips.

Pinnacle Systems Inc. (Booth 842) will present the NSD (New Switching Device) Safety Mat system. Feature advanced flexible electrodes (no rigid steel plates in mats) and a large 6x12 ft single mat capability. Any mat shape or contour is available. Provide visual recognition of the guarded zone and no programming is required.

Precision AirConvey (Booth 550) has released EnviroPulse 14, its latest oil mist system for the automated removal of pressure-sensitive adhesive label matrix waste. Unit applies a micro-thin film of food-grade mineral oil to the internal surfaces of the path via a fine mist. This coating is critical for keeping the adhesive material from adhering to tubing or other system components, eliminating expensive system clogs and costly downtime. The EnviroPulse 14 uses a 100 psi atomizer at the infeed nozzle to produce such a fine mist that very little oil is required. A typical application involves a single 1-second shot of oil every 5 minutes. This translates into less than 1 gallon of oil for every 24 hours of continuous operation. For most applications the unit will only need to be refilled every 14 days.

Process Sensors Corp. (Booth 943) will be showing its Guardian System Series of Web Profile Systems featuring the multiple scanner and transmitter PC-based system, standalone scanning system with Operator Interface, and economically priced starter system. The Guardian Series includes the MCT Nova series Near Infrared Transmitter, automatic scanning system with position encoder and web edge detection. The Guardian maps the measurement and position on large display with Ethernet communications and analog outputs. Wet end water-based coatings, dry end organic solid deposition, hot melt and film thickness and web temperature can be profiled accurately with a reasonable investment. Also showing the standalone MCT460 Near IR Transmitter.

QuadTech (Booth 931) highlights its newest in-line inspection and color measurement systems for the packaging market, including automated press control technologies. Color Quality Solution is an in-line color and ink control system with QuadTech Color Measurement System and SpectralCam to reduce make-ready time; an Inspection System performs 100% defect detection while printing (flexo, gravure and offset), rewinding, and laminating. PDF Verification provides absolute repeatability and the Web Viewing System is customizable, automated, and provides real-time digital view of the moving web for defect detection and minimized waste. Also displayed are Data Central for live/historical data integration with existing software and a Waste Management System.

QuadTech (Booth 931) highlights its newest in-line inspection and color measurement systems for the packaging market, including automated press control technologies. Color Quality Solution is an in-line color and ink control system with QuadTech Color Measurement System and SpectralCam to reduce make-ready time; an Inspection System performs 100% defect detection while printing (flexo, gravure and offset), rewinding, and laminating. PDF Verification provides absolute repeatability and the Web Viewing System is customizable, automated, and provides real-time digital view of the moving web for defect detection and minimized waste. Also displayed are Data Central for live/historical data integration with existing software and a Waste Management System.

Radiant Energy Systems Inc. (Booth 515) will exhibit drying, curing, and heating solutions. Can develop customized solutions using hot air, infrared, and combined hot air/IR technology. Pilot coating line is designed to help develop new products or improve existing processes for a wide range of converting applications. Is flexible for processes that include coating, drying, curing, laminating, annealing of plastic films, and printing on various substrates. Runs paper, film, foil, nonwovens, and other types of webs. Rick Luedtke will present at CEMA's educational sessions on Monday, February 9, at 1:30 p.m. He will discuss "Basic Industrial Drying Methods," including heat transfer variables, efficiency considerations, and the pros and cons of common drying techniques. Convention drying methods, infrared heating, and combination systems will be covered.

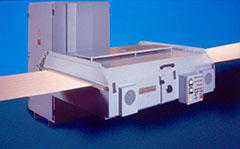

Radio Frequency Co. Inc. (Booth 969) will introduce the Macrowave (Radio Frequency-RF) Drying System for high-speed drying of water-based patterned glue and coatings. It selectively heats only the patterned coatings (wetted section) on the web and leaves the bound moisture in the substrate intact, thus preventing overdrying, distortion, and shrinking. Capable of operating at speeds up to 1,500 fpm, this system needs one-third to one-fifth of the floor space required for hot air and IR dryers, permits lower web temperatures, and provides up to 80% energy savings. Eliminates long dwell times associated with conventional heating methods, reduces make-ready because RF power is instant on/off, and handles webs up to 120 in. wide.

Radio Frequency Co. Inc. (Booth 969) will introduce the Macrowave (Radio Frequency-RF) Drying System for high-speed drying of water-based patterned glue and coatings. It selectively heats only the patterned coatings (wetted section) on the web and leaves the bound moisture in the substrate intact, thus preventing overdrying, distortion, and shrinking. Capable of operating at speeds up to 1,500 fpm, this system needs one-third to one-fifth of the floor space required for hot air and IR dryers, permits lower web temperatures, and provides up to 80% energy savings. Eliminates long dwell times associated with conventional heating methods, reduces make-ready because RF power is instant on/off, and handles webs up to 120 in. wide.

Sensortech Systems Inc. (Booth 356) will show the NIR 6000 Series of precision instruments for moisture measurement, coat weight, basis weight, and coating consistency. All are measured in real time providing in-line control capability. Analyzers offer reliable performance to measure and control paper, nonwovens, films, and other specialty web converting applications.

Sonic Solutions (Booth 1066) will show ultrasonic cleaning systems for anilox rolls. Company recently introduced the Phoenix line of cleaning systems. With this upgrade, your rolls are even more protected during the cleaning process. Can easily and effectively scale the system to clean rolls and sleeves of any size.

Speedmet Aluminum Ltd. (Booth 253) is now partnered with Non Ferrous Traders Inc. of New York, which will offer the full range of Speedmet products in the US, Mexico, and Canada. Company supplies wires for vacuum metallizing, offering three purity levels of aluminum for the most popular Speedmet 98 (99.80% Al) through Speedmet 99 for more demanding barrier applications, to Speedmet 100 (99.99%) for yarn grade and electrical applications. Also offers high purity copper wire, which is gaining demand for security hologram production.

Spooner Industries Ltd. (Booth 624) will demonstrate the latest developments in Spooner flotation and impingement technology, offering air flotation dryers and coolers, air impingement dryers and coolers, Air Turns, and Yankee Hoods for a wide range of converting processes. Typical applications include paper, adhesives, flexible packaging, films, tissues, board, nonwovens, and more. Learn more about the company’s state-of-the-art Test and R&D Centre at its UK-based head office, which is available to hire for confidential product and process trials and development work. New and existing customers can take advantage of Spooner’s High Speed Coating Machine (HSCM), along with various hand sample machines that can be used for the in-depth study and simulation of coating, heating, curing, drying, and cooling processes.

TAKK Industries (Booth 1217) will show IonStorm XR2 static eliminator, which projects a powerful field of ionization to effectively eliminate static electricity from a distance of more than 36 in. Unit emits pulsing waves of ions from dedicated negative and positive emitters, propelling waves of ions towards the static-charged surface. This neutralizes the charge on the surface, resulting in a powerful shockless pulsed DC ionization system. Models available in a variety of lengths. Easy to install and maintain, and multiple units can be connected and powered by a single standard electrical source.

TAKK Industries (Booth 1217) will show IonStorm XR2 static eliminator, which projects a powerful field of ionization to effectively eliminate static electricity from a distance of more than 36 in. Unit emits pulsing waves of ions from dedicated negative and positive emitters, propelling waves of ions towards the static-charged surface. This neutralizes the charge on the surface, resulting in a powerful shockless pulsed DC ionization system. Models available in a variety of lengths. Easy to install and maintain, and multiple units can be connected and powered by a single standard electrical source.

Unilux Inc. (Booth 634) will introduce the LED1 and LED3, the next two members of its H2LED Series of handheld strobe lights. The company also will have UV models for both these lights as well as its LED 2000 family of strobes. The LED1 replaces the Pocket Pixel, and the LED3 replaces the LED1XS (spotlight pattern) and LED1XF (floodlight pattern). The new lights are five times brighter than their predecessors, which were part of Unilux’s original LED lights, and the LED3 will be available as fixed-mount light with regular or UV LED diodes. They join the LED12 handheld strobe light, which debuted last year. Being able to use UV diodes in the LED strobes is a major advantage for converters and printers who use clear coatings and cold adhesives for their products.

Unilux Inc. (Booth 634) will introduce the LED1 and LED3, the next two members of its H2LED Series of handheld strobe lights. The company also will have UV models for both these lights as well as its LED 2000 family of strobes. The LED1 replaces the Pocket Pixel, and the LED3 replaces the LED1XS (spotlight pattern) and LED1XF (floodlight pattern). The new lights are five times brighter than their predecessors, which were part of Unilux’s original LED lights, and the LED3 will be available as fixed-mount light with regular or UV LED diodes. They join the LED12 handheld strobe light, which debuted last year. Being able to use UV diodes in the LED strobes is a major advantage for converters and printers who use clear coatings and cold adhesives for their products.

Vetaphone (Booth 521) will exhibit its range of corona and plasma treaters and iCorona and iPlasma generators, designed to offer premium solutions for the converting, coating, extrusion, printing, and laminating industries on web widths from 100 to 9,000 mm at all production speeds on one or both sides of the substrate. Company has introduced EASI-Plasma in cooperation with Coating Plasma Industrie in France. By replacing oxygen with gases and monomers, EASI-Plasms creates a range of new surface capabilities, including higher and longer lasting dyne values that can eliminate the need for use of primer or coating unit and hydrophobic or hydrophilic properties for anti-fog surfaces with only 5-50 nm thick nano-coating, for example.

Yazoo Mills (Booth 118) expands its Stock Core program to 103 sizes, including nine additional sizes of 3-in. I.D. x .250 cores.All stock cores range from 1/2 in to 60 in. long.

Yazoo Mills (Booth 118) expands its Stock Core program to 103 sizes, including nine additional sizes of 3-in. I.D. x .250 cores.All stock cores range from 1/2 in to 60 in. long.

For a complete list of exhibitors, click here

To view the floor plan, click here.

Conference Program

Sponsored by AIMCAL, there are nearly 40 educational sessions scheduled daily from 10:00 a.m to noon. The conference is divided into three parallel tracks each day as follows:

Tuesday, February 10

- Coating Quality

- Web Handling

- Extrusion Coating

Wednesday, February 11

- Coating Productivity

- Winding

- Web Slitting

Thursday, February 12

- Surface Treatment

- Coating Process

- Web Slitting

Sessions are 30 min each and attendees can mix and match based on their interests. For full details, click here.

In addition to the AIMCAL technical conference, CEMA (Converting Equipment Manufacturers Assn.) will hold two concurrent sessions on Monday, February 9, the day before the exhibit opens. These full-day seminars run from 8:30 a.m. to 5:00 pm. and cover “Coating & Drying” and “Slitting & Rewinding.”

PFFC's expert columnists and bloggers Kelly Robinson (Static Beat) and Mark Miller (Coating Matters) will present at the CEMA seminar. Kelly will present "Dealing With Static Electricity" at 9:00 a.m. and Mark will present "Coating Methods–Premetered" at 11:15 a.m.

For full details, click here.

Exhibit Hours

- Tuesday, February 10: 9:00 a.m. – 5:00 p.m.

- Wednesday, February 11: 9:00 a.m. – 5:00 p.m.

- Thursday, February 12 9:00 a.m. – 4:00 p.m.

For more information or to register, visit http://www.ice-x-usa.com.