Lithuanian Converter Opts for Speedmaster SX 74

- Published: May 22, 2012

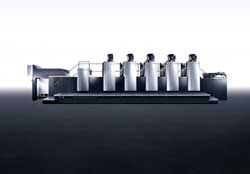

Lithuanian print shop Garsu Pasaulis in Vilnius has signed an order for a Speedmaster SX 74 from Heidelberg. The leading security printer in the Baltic States has opted for a six-color press with a chambered doctor blade coating unit.

Lithuanian print shop Garsu Pasaulis in Vilnius has signed an order for a Speedmaster SX 74 from Heidelberg. The leading security printer in the Baltic States has opted for a six-color press with a chambered doctor blade coating unit.

In addition to the print shop's core business of security printing, some 35% of the orders handled by its workforce of more than 300 are label and packaging printing jobs. In total, 70% of the labels it produces are printed on 65-90 gsm metallized special papers.

"We want to offer our customers the best products with the most advanced printing technology," explains Vytautas Vainikonis, joint owner of the print shop. "The new Speedmaster SX 74 is the best possible press for us. It enables us to meet our customers' stringent quality requirements and increase our productivity in the label segment." Currently the majority of the sheet-fed offset presses installed at the company are from another German press manufacturers.

The print shop processes jobs for customers in the beverage, food, tobacco, pharmaceuticals, cosmetics, and confectionery industries and also works with non-food manufacturers, civic institutions, banks, and insurance companies.

New SX model range offers outstanding automation

During drupa 2012, Heidelberg launched the new SX generation—a brand new model range. The new Speedmaster SX models combine the cutting-edge technology of the Speedmaster XL class with the tried-and-tested platform of the Speedmaster SM series to form a new performance class. The line is aimed directly at successful print shops that are looking to further boost their productivity.

During drupa 2012, Heidelberg launched the new SX generation—a brand new model range. The new Speedmaster SX models combine the cutting-edge technology of the Speedmaster XL class with the tried-and-tested platform of the Speedmaster SM series to form a new performance class. The line is aimed directly at successful print shops that are looking to further boost their productivity.

The new Speedmaster SX models are said to deliver outstanding print quality, high stability in production, intuitive and ergonomic operation, and a high level of automation. They offer a wide range of configurations with coating unit, perfecting device, and many additional features including various color measuring instruments. The new fully automatic plate changer AutoPlate Pro enables a complete plate change on a five-color press in less than two minutes.

In addition to the new ergonomic design, these models also benefit from the high-performance Prinect Press Center control station with the process-oriented Intellistart operator guidance system, which automatically determines and implements the optimum process sequence for job changes. The new Color Assistant Pro software ensures fully automated monitoring of the ink fountain liner, self-calibration of the ink zones, and automatic and intelligent adjustment of characteristic curves. This means that color presettings are even more precise and reproducible.

A new surface technology for the exchangeable jackets of impression and transfer cylinders—PerfectJacket Blue and TransferJacket Blue—ensures a far longer service life and much lower cleaning requirements. This increases the availability of the equipment significantly.