Winding Better Rolls

- Published: June 01, 2003, By Timothy J. Walker, TJWalker & Assoc. Inc.

It's not obvious how winding adds value to your product (it does), but it is obvious when it's done poorly.

Winding — the final step in many web converting processes — is like bagging groceries. You go through the store. Pick out bread, eggs, and milk. At the checkout line, the checkout assistant opens a bag, drops in your bread, then your eggs, then the gallon of milk — splat. Winding is like that. It seems easy enough, but done poorly, winding can turn 100% good product into waste very quickly.

One key to quality wound rolls is the winding nip. The winding nip is a roller, driven or idling, that remains in contact with the winding roll throughout its buildup. The winding nip has many aliases, including lay-on roller, pack roller, surface roller, and contact roller. Some of the same roll quality benefits also are found using a close cousin of the winding nip — the gap roller.

Q: Are winding nip rollers used in both surface and center winding?

A: Yes, winding nip rollers are used in both. You can't have a surface winding without a winding nip roller (a.k.a. surface roller). Pope reel winders have one large central drum that contacts the winding roll. A two-drum winder has two winding nips that cradle the winding roll (and often a third winding nip on top of the roll). Adding a winding nip to a center winder improves roll quality.

Q: Which is most common — surface or center winding?

A: If you survey winding equipment shown at the CMM show, center winding dominates the converting industry. This dominance is not because it is the best winding method, but because it is simpler to build and easier to automate roll transfers.

In the paper industry, you will see more surface winding for two reasons. First, paper roll properties allow winding to extremely large-diameter build-up ratios, where the final roll's diameter may be 20x the core diameter. If tensioning torque is generated from the roll's center — the definition of center winding — the torque required (tension × radius) will have a torque range impossible for most motors. Surface winding takes roll diameter out of the torque range requirements. Second, many paper winders use a simple “rip and tuck” roll transfer. If there is a core start wrinkle, the soft paper layers quickly mask them. You could never do a “rip and tuck” with films or foils without a lot of waste from wrinkles and impressions, so center winding and automated (or stopped) transfers are preferred.

Q: Which is better — surface or center winding?

A: It's not about which is better. They both have important niches. As mentioned above, surface winding is good for rolls with large build-up ratios. Surface winding often can wind at lower tensions than center winding and exerts less torque on the building roll (avoiding torque-related cinching). Center winders have more automatic cut and transfer options. For many products, center winding is better for winding multiple rolls on a common shaft, especially with differential winding bars.

Q: Why does a winding nip improve roll quality?

A: Winding nips do a better job of managing the web's last span and initial contact onto the winding roll. Mismanagement of the web's final span before winding is like the poor grocery bagger. A “well-bagged” roll will have less defects such as weave, dishing, telescoping, roll shape errors (non-cylindricity), wrinkling, excessive air entrainment, and loose winds. Understanding the importance of winding entry span length and the use of nip and gap rollers at winding will lower your waste and produce a better “package” for your next operation or customer.

Q: What are the benefits of a winding nip?

A: The winding nip has four main functions. First, it reduces the span length into the winding roll, reducing tracking errors and wrinkling. Second, it acts as a squeegee, reducing the air entrained into the winding roll. Third, it tends to form more cylindrical rolls. Finally, it tightens the winding roll.

Q: How does winding entry span length promote tracking and wrinkling defects?

A: The three sources of web tracking error are misalignment, diameter variations, and web bagginess. Winding rolls can have one or all of these errors, especially diameter variations. Because the web's flexibility goes up with span length cubed, the magnitude of tracking error from these sources will increase with longer entry spans.

Q: What is an example of span length increasing tracking error?

A: Many turret winders have wrinkles and tracking error during the index cycle. Entry-level turret winders have a winding nip in the primary winding position, but the nip doesn't contact the roll once the index cycle begins. As the roll indexes away from the winding nip, the winding entry span length increases. In many cases, the non-cylindrical winding roll and the long span formed during indexing will cause wrinkling or tracking error. For faster processes and thicker products, this will cause a high percentage of wasted product.

Q: How are indexing wrinkles eliminated?

A: In some designs, rollers on the turret that limit the span length during indexing are enough. More advanced winders keep winding nip contact throughout the index cycle.

Q: Where do roll diameter variations come from?

A: The cross-web caliper variations and slit edge quality create roll diameter variations. Winding conditions and material properties (such as the radial modulus) will determine whether winding magnifies or masks web thickness variations.

Q: How does a winding nip help?

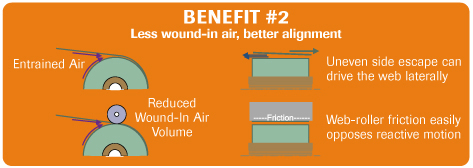

A: A winding nip, like most rollers, presents a uniform cylinder at the end of the span, therefore not inducing lateral tracking error. The winding nip then holds the web in place as it presses it onto the winding roll, ensuring a laterally aligned roll edge. The traction of the web to the winding nip holds the web in position, preventing web reaction to the airflow at the web-roll convergence.

Q: Do winding nips need to be cylindrical?

A: Yes, winding nips should be true cylinders.

Q: Should a winding nip be hard metal or compliant?

A: A compliant winding nip is best, since the compliant covering will reduce the cross-web nip pressure variations from roll diameter variations. An overly hard winding nip roller may ride only on the high diameter lanes, creating stress concentrations in the web.

Q: Can a spreader roller be used as a winding nip?

A: Since most spreader rollers are not cylindrical, they are not a good choice for a winding nip. If you need to ensure lateral tautness at winding, use a spreader roller just upstream of the winding nip. If the web is flat on the winding nip, it will be flat entering the roll.

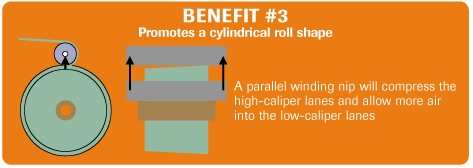

Q: Will a winding nip promote a cylindrical roll shape?

A: Yes. For many products, the winding nip pressure will compress the high diameter areas. With higher-speed winding, winding nips will allow more air to wind into the low diameter areas. Both effects tend to improve roll cylindricity.

Q: Should a winding nip be held parallel or allowed to float to the roll's profile?

A: Floating winding nips can promote tracking errors. Most winding nips are designed to maintain their tram and level (parallelism).

Q: How does a winding nip reduce air wound into a roll?

A: Air is entrained with the moving web's surface on both the entering web and the outside of the winding roll. The boundary layer of air travels at nearly the web's speed. Without a winding nip, the high- velocity air creates high pressure at the web-roll convergence. An unnipped web, which creates only low pressure (less than 1 psi), can be lifted by the air velocity pressure. A winding nip can create more than 100 psi, opposing and compressing the entrained air's pressure.

Q: Is entrained air bad for roll quality?

A: Not always. Air can be a great masker of caliper and diameter variations. However, if the air bleeds out over time, the roll layers will settle to a small diameter and loosen the roll. More air inside a roll will increase pump downtime for vacuum processes, such as metallizing. Winding in a vacuum process quickly reveals the benefits of entrained air. Without entrained air, caliper variations translate strongly into diameter variations, and often wrinkling.

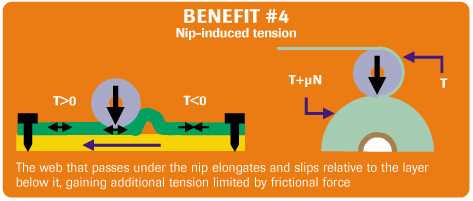

Q: How does a winding nip increase roll tightness?

A: More winding nip force creates a tighter roll, similar to winding with higher tension. Dr. Keith Good at the Oklahoma State University Web Handling Research Center did some excellent work over the last decade to understand and predict how a winding nip increases tension.

To understand the “nip induced tension” effect, think about rolling a cart over a rug. The nip force of the cart's weight on the wheels has a rolling pin action, elongating the rug. As the cart rolls in one direction, the rolling wheels elongate and pin down the stretched rug. The elongated material is pushed ahead of the cart, forming a bulge in the carpet.

If you held the rug at both ends while you rolled the cart, you would find the rug behind the cart got tighter and the rug section ahead of the cart got looser. This same elongating and pinning happens with a winding nip, only in the reverse direction. The web moving under the nip is elongated and pinned onto the winding roll. Therefore, the web tension increases as the web passes under the winding nip.

Q: What determines how much added tension is created by a winding nip?

A: In both the rug and winding nip case, the top layer (or rug) must slide relative to the surface below it to elongate. If the layer (or rug) can't slide, it can't elongate. The interesting finding from Dr. Good's work is the winding nip tightening must exceed the break-away friction, but it also is limited by it. The winding nip cannot induce more tension than the frictional force at the sliding point. Therefore, front-to-back web coefficient of friction (or rug to floor friction) determines how much elongation or tensioning occurs for a given winding nip load.

Q: Is wound-in tension from a winding nip a benefit?

A: It may be a benefit, but mostly it is important to understand when it increases roller tightness and when it doesn't. The benefit of nip-induced tension is that it can reduce the tension that must be transmitted through a center winding roll. Too much center torque can lead to cinching and telescoping. Winding nip tension can create a tighter roll without these defects.

Q: What is the best geometry for the winding nip?

A: There should be some wrap on the winding nip, so the web is placed onto the roll by the nip. If the web touches the roll then later is nipped, some of the anti-wrinkle and improved tracking benefits are lost. A winding nip after the web tangent point still will have some air squeegee and induced-tension benefits.

The best winding nip geometry is a 180-deg wrap. This does two things. First, it orients web tension perpendicular to winding nip force, making the winding nip load independent of tension. Second, if the winding nip roller deflects or skews, a 180-deg nip wrap ensures it will be perpendicular to the entry span, reducing the likelihood of tracking or wrinkling.

Q: What is a gap winding?

A: A gap winding is similar to a nip winding, but it does not contact or load against the winding roll. Instead, as the name implies, the gap winding positions the final roller at a small gap from the winding roll's outer surface, creating an extremely short entry span.

Q: What are the benefits of a gap roller relative to a winding nip?

A: A gap roller has the same anti-wrinkle and improved tracking benefits of a pack roller. However, since it doesn't create pressure or force on the outer layer, there is no air squeegee or nip-induced tension benefits.

Q: When is a gap roller used instead of a winding nip?

A: If you want the tracking and wrinkling benefits, but have a pressure- or tension-sensitive product, then gap winding is a better option. If your product has high friction or adhesive coating, the outer layer will not slip relative to the winding roll, so you can't benefit from nip-induced tension. If you find entrained air improves your winding quality, gap winding is better for your product.

The function of the last roller before entering the winding roll is critical to optimized roll quality. Nip and gap winding both will reduce lateral errors and wrinkling associated with long entry spans and roll variations. Winding nips will reduce entrapped air, and the associated loose wind or vacuum process pump downtimes. Winding nips are an alternate variable to increase roll tightness and may promote roll cylindricity.

Just like a good grocery assistant will put your milk and eggs in a bag safely, nip and gap winding will secure your web safely onto the winding roll.

Timothy J. Walker has 20+ years of experience in web handling processes. He specializes in web handling education, process development, and production problem solving. Tim writes the monthly “Web Lines” column in PFFC. Contact him at 404/373-3771; This email address is being protected from spambots. You need JavaScript enabled to view it.

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).