Iggesund Invercote Paperboard Used for Jimmy Choo Perfume Box

- Published: April 17, 2018

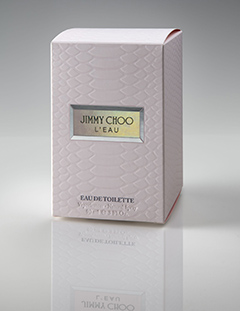

IGGESUND, SWEDEN | In the world of packaging, it is sometimes complicated to achieve something that looks simple, minimalist and elegant. The paperboard carton for Jimmy Choo’s L’EAU that was launched in summer 2017 is a clear example of this. Its color is pale pink apart from the brand, the name of the contents, and the fact that it is an eau de toilette. Yet the packaging has passed through 12 finishing stages.

The carton is made of Invercote from Iggesund Paperboard. Conversion is by the distinguished French printing company Draeger on behalf of Interparfums. The packaging is offset printed on both the inside and outside. The printing on the inside is in a pale pink shade, which creates the mood around the bottle. Externally the packaging has a blind-embossed snakeskin pattern plus two rows of text on the front. The outside is also laminated with soft touch film, matte varnished, and foil embossed with both silver film and holographic film.

“Our choice to use Invercote G was motivated by the fact that its smooth surface allowed a very faithful reproduction of our design in terms of color and hot foil stamping. It also brings great embossing properties to achieve the impressive snakeskin pattern on the whole packaging” says Axel Marot, supply chain & operations director at Interparfums. For producers of advanced paperboard packaging involving many finishing stages, one paperboard property can be of critical importance to the end result: dimensional stability. This may not be the first thing people consider when choosing a material but experienced converters always include it in their calculations.

“If you have twelve finishing stages and get a misregister at stage ten, you don’t just lose the material but also all the work you invested prior to that,” explains Edvin Thurfjell, product manager for Invercote. “In today’s world of ever-increasing time pressure you also risk missing delivery times – and for many projects that just cannot be allowed to happen.”

In Invercote’s case the secret is a combination of a high proportion of long cellulose fibers from pine and spruce plus the sulphate process that extracts these fibres in a gentle way. In addition, the paperboard is constructed in several layers. This is not only important for dimensional stability; it also reduces the risk of cracks in creases compared with single-ply paperboard and paper. However, there is no simple measurement of dimensional stability that customers can find among the lists of specifications from paperboard manufacturers.

“For people who do read these specifications, two clues are high values for tearing strength and tensile strength. But I believe that a large proportion of our customers have discovered this strength from their own experience,” Thurfjell says.

As a product manager he believes, naturally enough, that people should pay more attention to their choice of material.

“As someone who is interested in packaging, I think it’s a pity when people compromise on their choice of material and endanger all the work that’s been invested before the production even starts. When people hire the best creatives and choose star photographers and models but don’t understand that the quality of the packaging material must be correspondingly high, then I do wonder if they’re thinking along the right lines.”