OMET Press Is a Research Aid

- Published: December 04, 2014

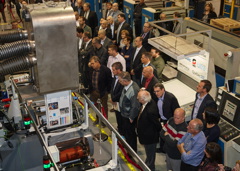

LECCO, ITALY | OMET recently helped celebrate the opening of the Print Workshop of the Printability and Graphic Communications Institute (ICI) in Montreal, QC, Canada, where a newly installed OMET Varyflex V2 multi-process press was on view.

Planned technological projects using the Varyflex will be mainly in the field of printable electronics and their prototyping. OMET says the press is one of a kind, a Varyflex V2 platform in-line multi-process press that has been adapted to the needs of ICI and its partners. It is said offer full interchangeability of the printing processes and the greatest register accuracy.

ICI chose a full-size press in order to come close to the reality of printers and to be able to easily transfer the prototypes. The goal was to get closer to manufacturing and not make something that exists only in a laboratory.

Reportedly, the new press is able to go from silkscreen printing to gravure or flexography in the order needed to make the prototypes. “We needed a unique flexibility,” explains ICI’s Régent Bernier. “We can print thin plastic films or thick cardboard but also paper on the same printing press, and we can use three different printing processes in five stations.” The press was made so that additional units can be added to allow ICI to offer more possibilities.

One of the goals is to add something more than color to printed products and the final goal is to give them functionalities. “Conducting current, changing colors, or ensuring a controlled release of an active substance” are examples of processes given by Christine Canet, director of ICI’s consulting services and applied research. According to her, the goal is to target applications that are made for rotary presses and that are both innovative and industrial.

The team behind the project wants a register positioning accuracy that it says does not exist yet. Changes will be made to the printing press in association with OMET to reach the desired results under a three-year partnership contract. “Together, we will push register accuracy to the limit of technology,” says Canet.

Alain Bergeron, ICI’s director of business development, says that it is important to have a quick turnaround while keeping the costs as low as possible. According to Canet, the savings are due to the efficiency of the process and the fact that the Varyflex V2 can print products that are really different on the same production line, in one single pass. “The printing processes allow us to put the substance exactly where it is needed,” says Chloé Bois, ICI’s projects manager.

ICI says the Varyflex V2 was developed so that it could work with small amounts of ink while minimizing waste.

Canet says OMET is more than just a supplier. “It is also a partner that will be part of the adventure for the next three years. It is a big player that has decided to invest in modifications to enter into a highly specialized market.”

This email address is being protected from spambots. You need JavaScript enabled to view it.