Digital Gone Wide

- Published: December 31, 2004, By Nsenga Byrd Thompson, Associate Editor

Digital Workflows

While many within the converting industry still weigh the benefits of digital printing, Carolina Container Co., a 76-year-old corrugated converter, took a giant leap forward eight months ago. Looking to create new opportunities for its ever-growing point-of-purchase and display business (and most recently the trade show arena), the company created Digital Highpoint, a division solely dedicated to all that is digital.

Explains Charles Sanders, director of sales at Digital Highpoint, "We first learned about digital print directly onto substrates such as corrugated about three years ago. At the time, it was just a passing thing; we weren’t really looking at that opportunity. But when the time came to look, that’s when we began to [research] digital printing.

"We were looking for an opportunity to increase our customer base through our print capability. A lot of the industry [that was] in this area is no longer here, because it has moved off shore or doesn’t exist any longer," Sanders continues. "But we’re a company that’s 76 years old, and we’re looking for opportunities…and we viewed digital as an opportunity not only to increase [our] customer base but also to add profits to the bottom line."

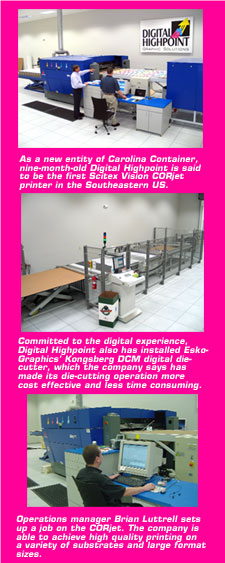

With just five employees and a busy sales force, Digital Highpoint is off and running, thanks to its installation of the Scitex Vision CORjet digital ink jet press. Hailed as the first industrial digital ink jet press for corrugated applications, the CORjet is described as a complete system comprising its own RIP software unit and system controller, automatic loader and unloader, print engine, and drying unit.

Using the same standard-format artwork files used for digital and litho production, the CORjet prints with four- or six-color configurations using environmentally friendly water-based inks developed and produced by Scitex Vision and approved for use in food packaging by the US Food and Drug Administration.

Digital Highpoint is said to be the first CORjet printer in the southeastern US. As a large-format digital printer, the division prints four colors at 600 dpi on a print area as large as 62 x 118 in. The press accepts an assortment of substrates including all corrugated board, a variety of flutes, and Plasti-Corr.

In the search to build a digital printing business, Jack Richards, director of operations, describes the road leading to the CORjet. "We really looked at a lot of different pieces of digital equipment that print on a wide variety of substrates. We were drawn to the Scitex because it is the only one set up specifically for corrugated."

Richards continues, "It’s automatic feed and automatic take-off. The speed we can produce on the CORjet is better than anything else we found in the market. And with our background being corrugated, we felt the CORjet was a better fit for us."

The Digital Edge

Adding digital solutions to its list of converting capabilities, which includes converting paper supplied by Appleton Papers, was a learning experience, but Digital Highpoint believes its installation of the CORJet has put it at the cutting edge of digital printing.

One critical aspect of the digital press, Sanders contends, has been the CORjet’s ability to create quick turnaround times for customer print jobs.

"[The customer] can supply the art or we can develop the art, and within two hours, we can have the customer approval," says Sanders.

Richards also has high regard for CORjet’s ability to handle the large print areas Digital Highpoint’s customers demand. "In our industry, the fact that we can print 62 inches by 118 inches is critical. Envision 62 inches by 118 inches—to print on a surface that big and do it without print plates or without any tooling!"

Extolling the large-format capabilities and quick turnaround, Sanders is quick to add that print quality isn’t sacrificed. "The quality and color management have been excellent, and we’ve had that comment from people within our trade."

The total package CORjet consistently offers Digital Highpoint is opening new doors for the young division. "You can envision your application as each opportunity comes to you, and that’s the truth," Sanders proclaims. "If I clearly can show [potential customers] examples—because that is something we like to do to get our prospective customers in the facility—they can then understand better what our capabilities are. Now, as clients get various requests, they come to us," Sanders adds.

All That’s Digital

Along with its digital printing capabilities, Digital Highpoint houses a 72-in.-wide Neschen Accutech UV coater, and the company also has an Esko-Graphics Kongsberg DCM digital die-cutter that Richards says has made die-cutting a snap. The DCM features a fully automatic load and unload mechanism, which reportedly handles up to a half-ton of corrugated material, and a vacuum system with a component that feeds sheets from the intake pile as it simultaneously removes finished sheets from the cutting platform.

The company has several traditional die-cutters in which an operator lays out one sheet and then cuts the sheet out manually. Esko-Graphic’s DCM 24 offers automatic feed and automatic take-off, which Richards says has made it a cost-effective die-cutting solution and a huge time-saver.

Moving Forward

With just eight months behind it, Digital Highpoint has its sights set on the future.

"We have plans, and we have room for growth based on the capabilities the CORjet gives us," comments Sanders. "We haven’t fully realized it yet; we’ve only scratched the [surface] in the markets we serve. But we feel there are many opportunities for using the CORjet. We’re exposed to markets now we have never been exposed to before."

Adds Richards, "As we continue in the process, and we want to, it might be that we end up with a different print medium in the future that allows us to print on other substrates that we’re not capable of right now. We’re looking for Scitex to show us whatever there is for the future."

As for what the future holds, Richards makes it clear, "Our competition goes where the print industry is. Digital Highpoint is going where the print industry will be."

CONVERTER INFO:

Digital Highpoint, a div. of Carolina Container Co.

909 Prospect St.

High Point, NC 27260

336/883-7146; carolinacontainer.com

SUPPLIER INFO:

Scitex Vision—scitexvision.com

Esko-Graphics—esko-graphics.com

Neschen-AccuTech Corp.—neschen-accutech.com

Appleton Papers—appletonpapers.com