Why do I have these bubbles in my finished product?

- Published: January 03, 2012, By Tom Bezigian

Happy New Year to everyone. I hope you all had an enjoyable holiday season. Now that the calendar has changed again, it's back to business.

As complicated as the extrusion process is, with all its nuances of equipment variations, materials, finished product requirements, ancillary equipment, etc., I have observed over the years that there are a core set of issues that affect every processor. I will touch on the subject of degradation as manifested by bubbles or voids in the finished product.

Voids in a finished film, sheet, profile or part are generally considered to be unacceptable. Since it is difficult to have ZERO voids (or zero anything for that matter), quality standards are established to determine acceptable levels of voids. Observing voids or other defects is usually straight-forward. Eliminating them can be more challenging. It is important to not that quality cannot be inspected in... it has to be built in from the beginning.

Depending on the process used, voids can have different root causes. Simply put, a void is an empty space that should be occupied by a mass of material. With regard to extrusion, entrapped air in the feed section of the screw and polymer degradation are the main culprits behind voids. In addition to the myriad of extrusion issues, extrusion laminations can have entrapped air bubbles which appear to be voids. I will focus on voids caused by polymer degradation in the extruder and die in this article.

Polymers degrade when excessive energy is imparted to the polymer chain. As far as the actual polymer molecule is concerned, temperature is motion, and motion is temperature, and both are energy. Energy can either be thermal or mechanical, as that caused by excessive in shear rate. The bonds within the molecule have a certain bond strength, and when energy is imparted to the bond that exceeds that bond strength, the bond is broken. This is BAD. When a bond is broken, free radicals (electrons) are liberated. Free radicals are extremely energetic, and react immediately with anything in close proximity.

Depending on the polymer, one of two things can happen: either molecular weight will increase, or it will decrease. ethylene-based polymers tend to crosslink in the presence of free radicals, and thus molecular weigh is increased. This leads to the formation of gels. Propylene-based polymers are subject to chain-scission in the presence of free radicals, and thus molecular weight is reduced. While both mechanisms can lead to the formation of gaseous species, chain scission is more likely to produce voids.

One reader had an issue with voids in their propylene-based extrusion. They have a complex process which uses a twin-screw extruder to compound additives in-line to feed an extruder and die to make a finished web. Though the compound was highly stabilized, the finished web had many (thousands) of voids.

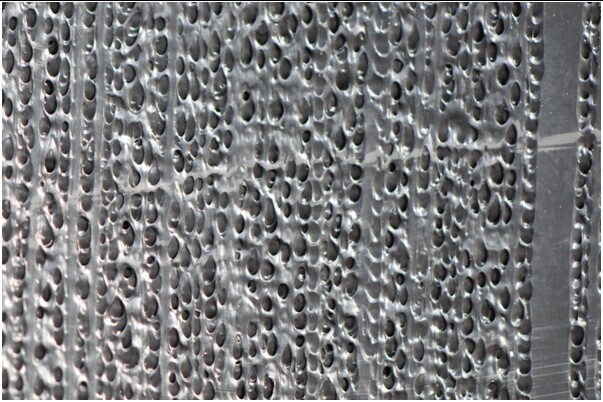

Example of voids in an extrudate. Photomicrograph at 20X.

An examination of the process showed all temperature and pressure parameters to be within specification, yet the voids existed. This points to the cause as NOT being temperature induced, but shear induced. As a consultant, I am very sensitive to the cost of taking machines off-line, so many variables were investigated. Finally, we opened one of the sealed ports in the feed-end of the twin-screw extruder and, voila... fire erupted. This is obviously not a desired condition, and sadly, it was not the first time I have seen this.

When a polymer ignites spontaneously in air, the temperature of that polymer is in excess F of 675° F (360° C). This is excessive for any polymer process, and is indicative of excessive shear rate in that zone. Screw elements were changed out, and the problem alleviated. Had this been a single screw extruder, a screw change would have been required to impart less shear energy to the polymer.

Until next time.

Tom Bezigian